A lithium ion battery material and its preparation method using superassembly and dealloying

A lithium-ion battery and dealloying technology, applied in nanotechnology for materials and surface science, battery electrodes, secondary batteries, etc., can solve problems such as poor controllability, complexity, and low performance of lithium-ion batteries, and achieve composition Controllable structure, improved electrochemical performance, suitable for large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

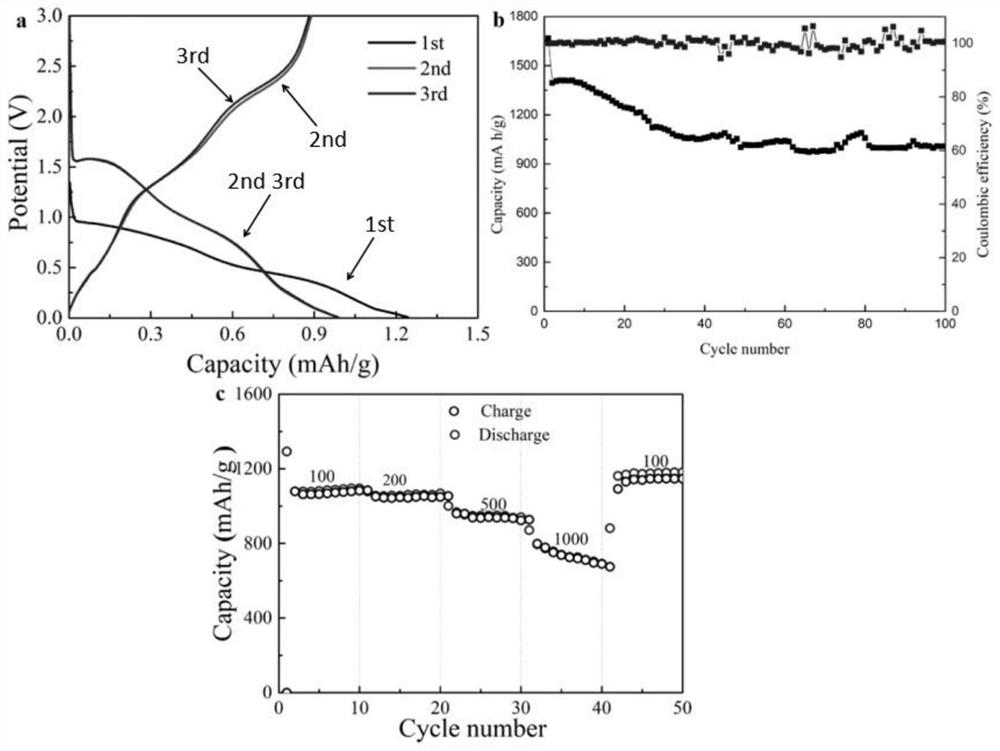

Embodiment 1

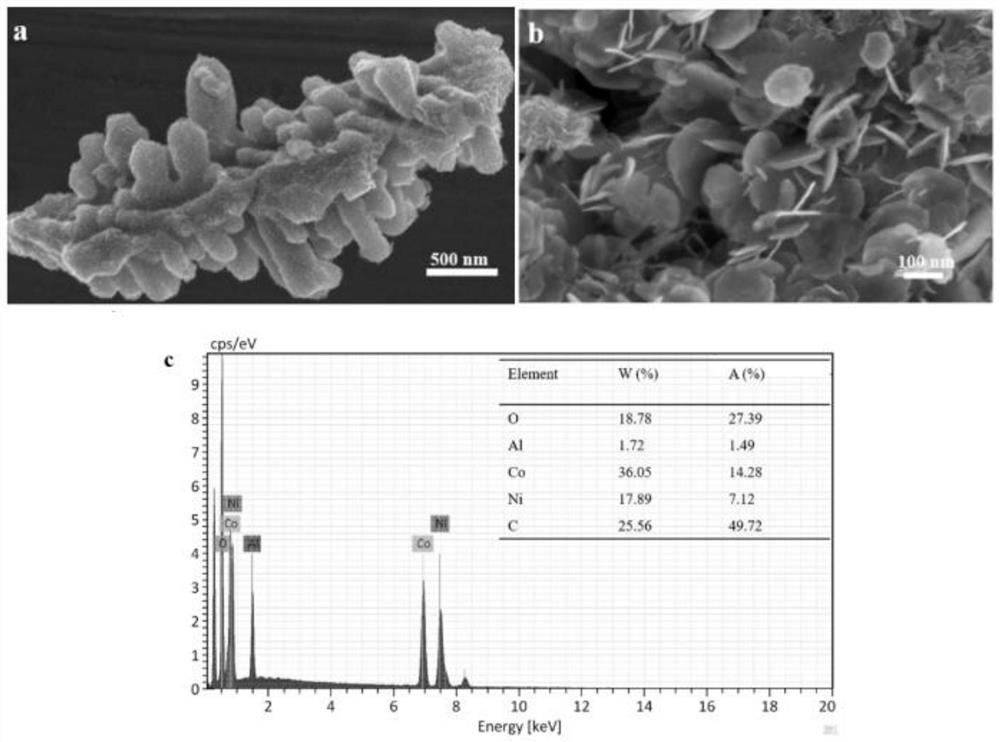

[0044] Step S1, 1g Co 5 Ni 15 Al 80 The alloy flakes were placed in 10 mL of hydrogen peroxide solution (3M), 100 mL of sodium hydroxide solution (2M) was added, magnetically stirred at 2000 rpm, and freely corroded at room temperature of 25 °C for 8 h to obtain corroded dealloyed materials.

[0045] Step S2, take 0.2 g of the corroded dealloyed material, place it in 50 mL of ethanol and ultrasonicate for 30 min, add 1 mL of aminopropyltrimethoxysilane, ultrasonicate for 30 min, stir for 1 h, centrifuge, and wash with ultrapure water 3 times to obtain a precursor.

[0046] In step S3, graphene oxide powder is prepared by the hummers method, and 20 mg of graphene oxide is added into 40 mL of ultrapure water and ultrasonicated for 1 h to prepare a graphene oxide dispersion liquid. Mix the precursor obtained in step S2 with the graphene oxide solution, and magnetically stir for 1 h at 25° C. and a rotating speed of 2000 rpm to obtain a mixed solution.

[0047] Step S4, add 50 ...

Embodiment 2

[0059] On the basis of embodiment 1, the difference is:

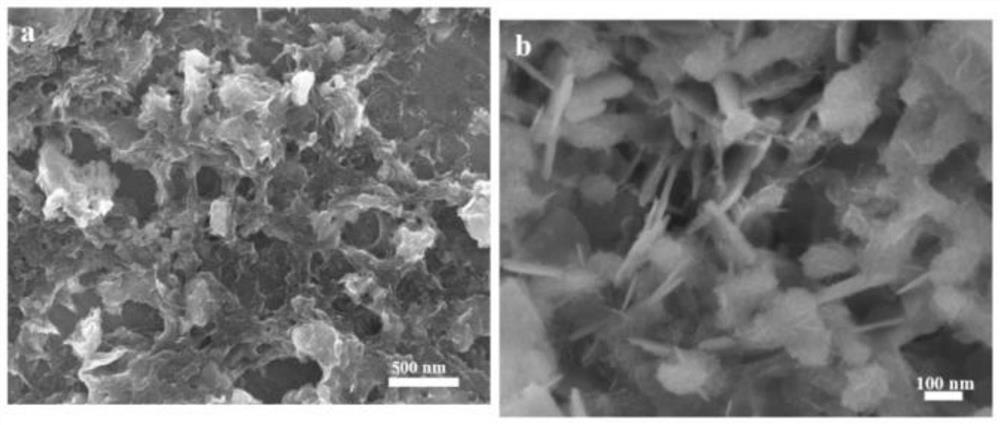

[0060] In step S1, free etching was performed at room temperature of 25°C for 2 hours.

Embodiment 3

[0062] On the basis of embodiment 1, the difference is:

[0063] In step S1, free etching was performed at room temperature of 25°C for 12 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com