Nano silver capable of being scattered in hydrophobic system and preparation method and application thereof

A hydrophobic, nano-silver technology, applied in the field of nano-materials, can solve the problems that have not been mentioned, narrow application range, reduce the conductivity of nano-silver, etc., and achieve the effect of good dispersion and strong chemical bonding ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0059] 1. Synthesis of nano-silver modifier:

[0060] Take 4.2g polyoxyethylene 400 fatty acid ester, 2.5g N-tert-butyl-L-serine, 3.2gDMAP, 4.2gEDC HCl, put them into a 250ml reaction flask, add 180ml dichloromethane, and place at room temperature, The reaction was stopped after 2-3 days of high-speed stirring, and the sample was taken out and washed and purified to remove unreacted serine and catalysts DMAP and EDC hydrochloride. Obtain the desired one end containing amino group, the other end contains the nano-silver modification agent of hydrophobic component. The structural formula of the modifier is as follows:

[0061]

[0062] 2. Synthesis of spherical nano silver:

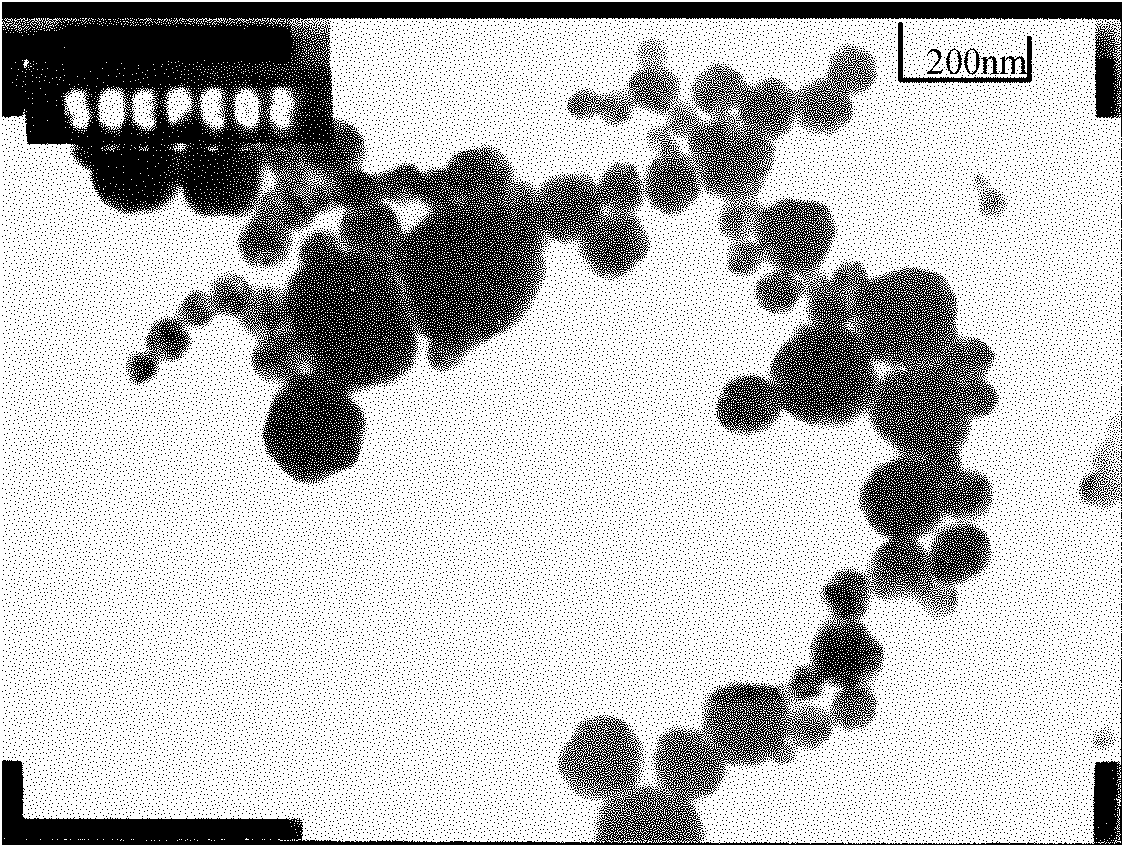

[0063] Dissolve 0.17g of silver nitrate in 20ml of deionized water, put it in a 100ml reaction bottle, stir at a high speed at 25°C, then slowly add 20ml of hydrazine hydrate (purity: 60%) to the aqueous solution of silver nitrate, and the addition ends Then react for about 2-3 hours. The TEM photogr...

example 2

[0078] 1. Synthesis of nano-silver modifier:

[0079] Feed nitrogen into the 500ml three-necked reaction flask, and maintain high-speed mechanical stirring, remove the oxygen in the reaction flask, then dissolve 0.121mol N-tert-butyl-L-serine and 0.109mol triethylamine in 300ml treated anhydrous Tetrahydrofuran, and the solution was added to the above-mentioned three-necked reaction flask, then it was placed under cooling and stirring at -20°C, and 0.198mol of treated anhydrous lauroyl chloride was slowly added, and the reaction was maintained at -20°C for 10 hours, and then reacted at -5°C for 5 hours, and then distilled off the solvent in the system under reduced pressure. Obtain the initial product lauroyl-N-tert-butyl-L-serine, then take 60.2mmol of lauroyl-N-tert-butyl-L-serine and 0.301mol of trifluoroacetic acid, add to 100cm 2 Reaction in dichloromethane at room temperature for about one hour, and then remove the unreacted TFA in the solution system. Then use 4mol·dm...

example 3

[0095] 1. Synthesis of modifiers:

[0096] Take 160ml of styrene, 150mg of initiator AIBN (azobisisobutyronitrile), and 510mg of chain transfer agent thioacetic acid, make a solution and add it to a 250ml single-port reaction flask, and continuously feed nitrogen gas for 1h under ice-water bath conditions to thoroughly Oxygen was replaced therein, and then the water bath was heated to 60° C. under the protection of nitrogen and stirring slowly to start the polymerization reaction. After 60min, change the water bath into an ice bath to terminate the reaction to obtain thioacetoxypolystyrene. The structural formula of the modifier is shown in the figure below, where n=10000:

[0097]

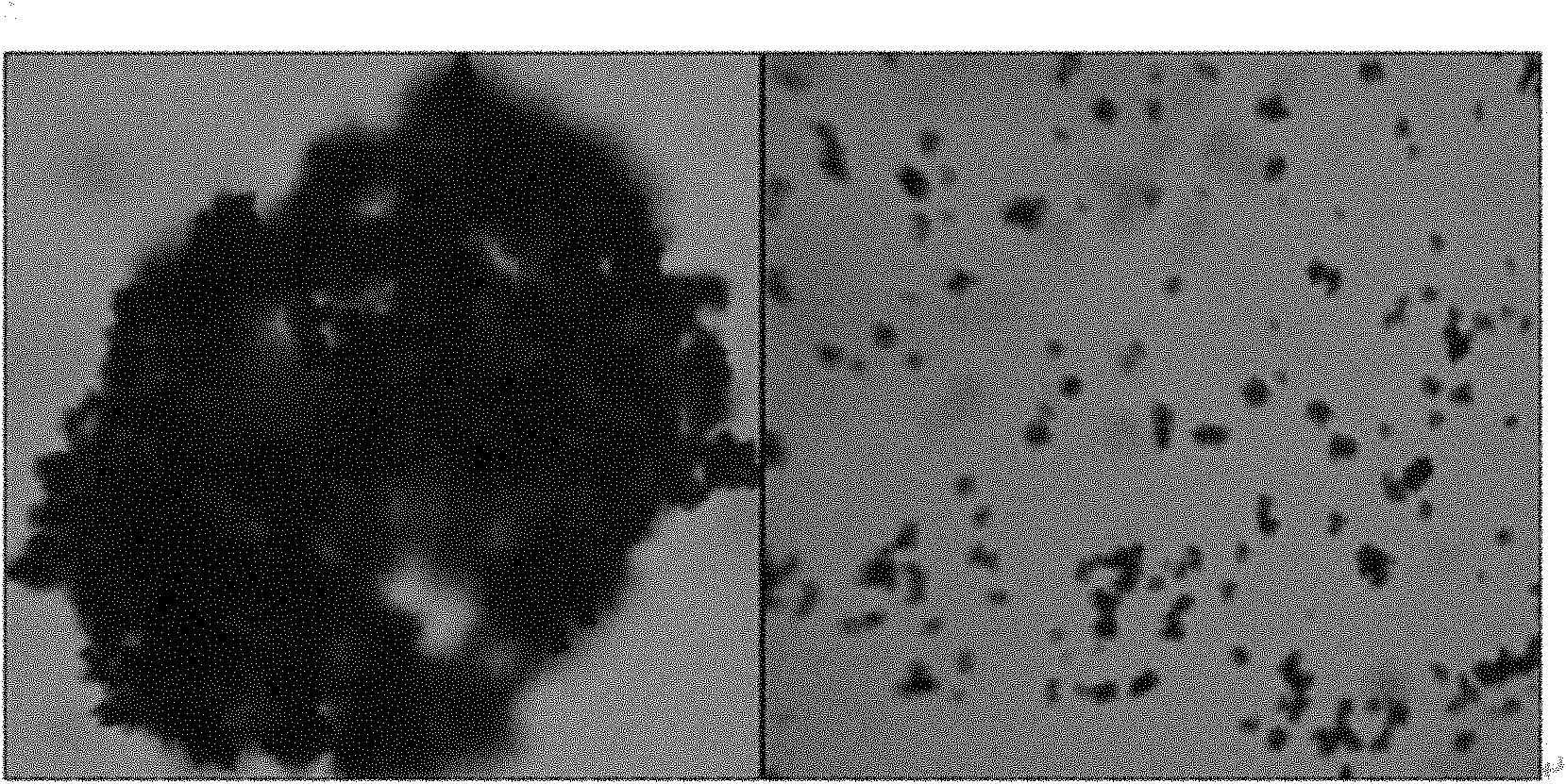

[0098] 2. Synthesis of rod-shaped silver nanoparticles

[0099] Take 5ml of ethylene glycol with water removed, add it to a 25ml single-necked reaction flask, stir at 180°C for about 1 hour, then add 0.5ml of ethylene glycol solution containing sodium sulfide (concentration: 1mM), after 5min,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com