High performance composite long fiber reinforced polypropylene material and preparation method thereof

A polypropylene material and long fiber technology, which is applied in the field of high-performance composite long glass fiber reinforced polypropylene material and its preparation, can solve the problems of poor interphase compatibility, increased material processing flow and cost, etc. The effect of strong resistance, rigidity and impact resistance improvement, and high fiber surface activation energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

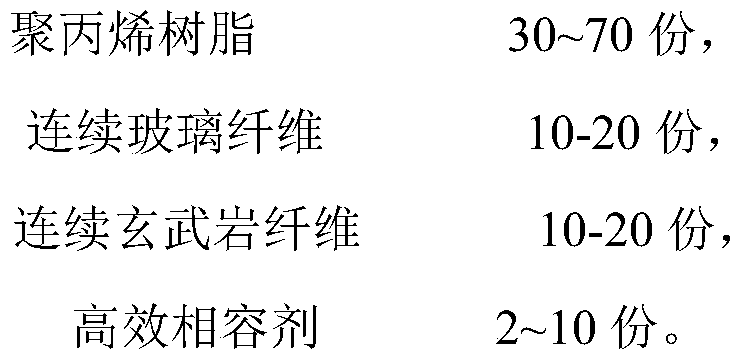

Method used

Image

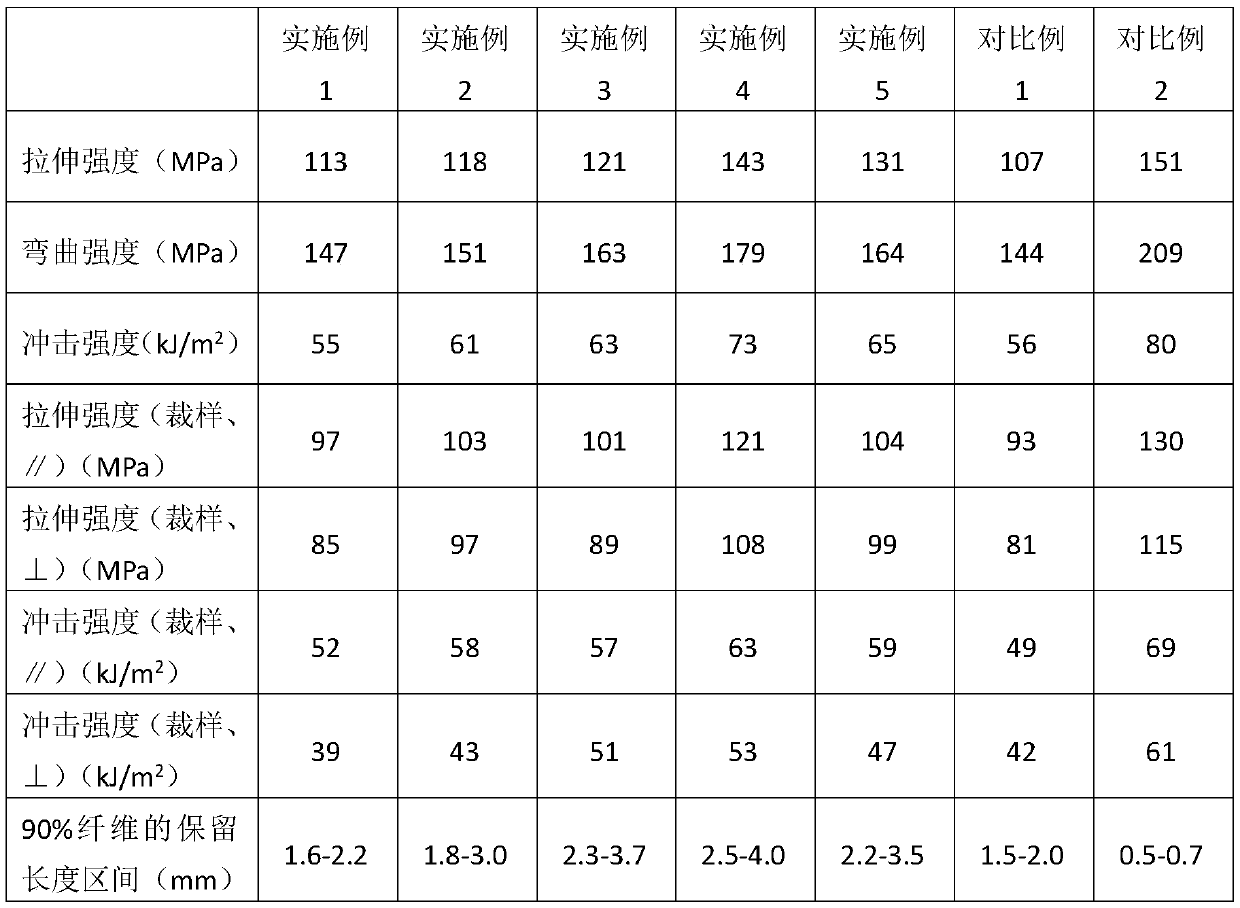

Examples

Embodiment 1

[0036] Take by weighing polypropylene resin, high-efficiency compatibilizer by the embodiment 1 data shown in table 1, mix homogeneously, obtain mixed raw material:

[0037] The dried mixed raw materials are placed in the main feeding bin of a tightly meshed co-rotating twin-screw extruder, and fed into the barrel of the extruder through the feeding screw. The diameter of the extruder screw is 36mm. The length-to-diameter ratio L / D is 44, and the temperature of each zone of the main barrel from the feeding port to the nozzle outlet is set as: 100°C, 190°C, 200°C, 215°C, 220°C, 220°C, 220°C, and the main engine speed is 300 rpm, the resulting molten polypropylene resin is injected into the impregnation cavity through the die of the extruder.

[0038] The continuous glass fiber and continuous basalt fiber are respectively placed on the creel, pre-tensioned by the tension roller to divide the yarn, and then they are exported from different bobbins and arranged in parallel, and th...

Embodiment 2

[0042] Take by weighing polypropylene resin, high-efficiency compatibilizer by the embodiment 2 data shown in table 1, mix homogeneously, obtain mixed raw material:

[0043] The dried mixed raw materials are placed in the main feeding bin of a tightly meshed co-rotating twin-screw extruder, and fed into the barrel of the extruder through the feeding screw. The diameter of the extruder screw is 36mm. The length-to-diameter ratio L / D is 44, and the temperature of each zone of the main barrel from the feeding port to the nozzle outlet is set as: 100°C, 190°C, 200°C, 215°C, 220°C, 220°C, 220°C, and the main engine speed is 300 rpm, the resulting molten polypropylene resin is injected into the impregnation cavity through the die of the extruder.

[0044] The continuous glass fiber and continuous basalt fiber are respectively placed on the creel, pre-tensioned by the tension roller to divide the yarn, and then they are exported from different bobbins and arranged in parallel, and th...

Embodiment 3

[0046] Take by weighing polypropylene resin, high-efficiency compatibilizer by the embodiment 3 data shown in table 1, mix homogeneously, obtain mixed raw material:

[0047] The dried mixed raw materials are placed in the main feeding bin of a tightly meshed co-rotating twin-screw extruder, and fed into the barrel of the extruder through the feeding screw. The diameter of the extruder screw is 36mm. The length-to-diameter ratio L / D is 44, and the temperature of each zone of the main barrel from the feeding port to the nozzle outlet is set as: 100°C, 190°C, 200°C, 215°C, 220°C, 220°C, 220°C, and the main engine speed is 300 rpm, the resulting molten polypropylene resin is injected into the impregnation cavity through the die of the extruder.

[0048] The continuous glass fiber and continuous basalt fiber are respectively placed on the creel, pre-tensioned by the tension roller to divide the yarn, and then they are exported from different bobbins and arranged in parallel, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com