High-strength Mo-Ti-Zr-CNT molybdenum alloy composite material and preparation method thereof

A mo-ti-zr-cnt, composite material technology, applied in the field of high-strength Mo-Ti-Zr-CNT molybdenum alloy composite material and its preparation, can solve the problems of unsuitability for large-scale production, high price, etc. The effect of increasing hardness, enhancing grain boundary bonding force and increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

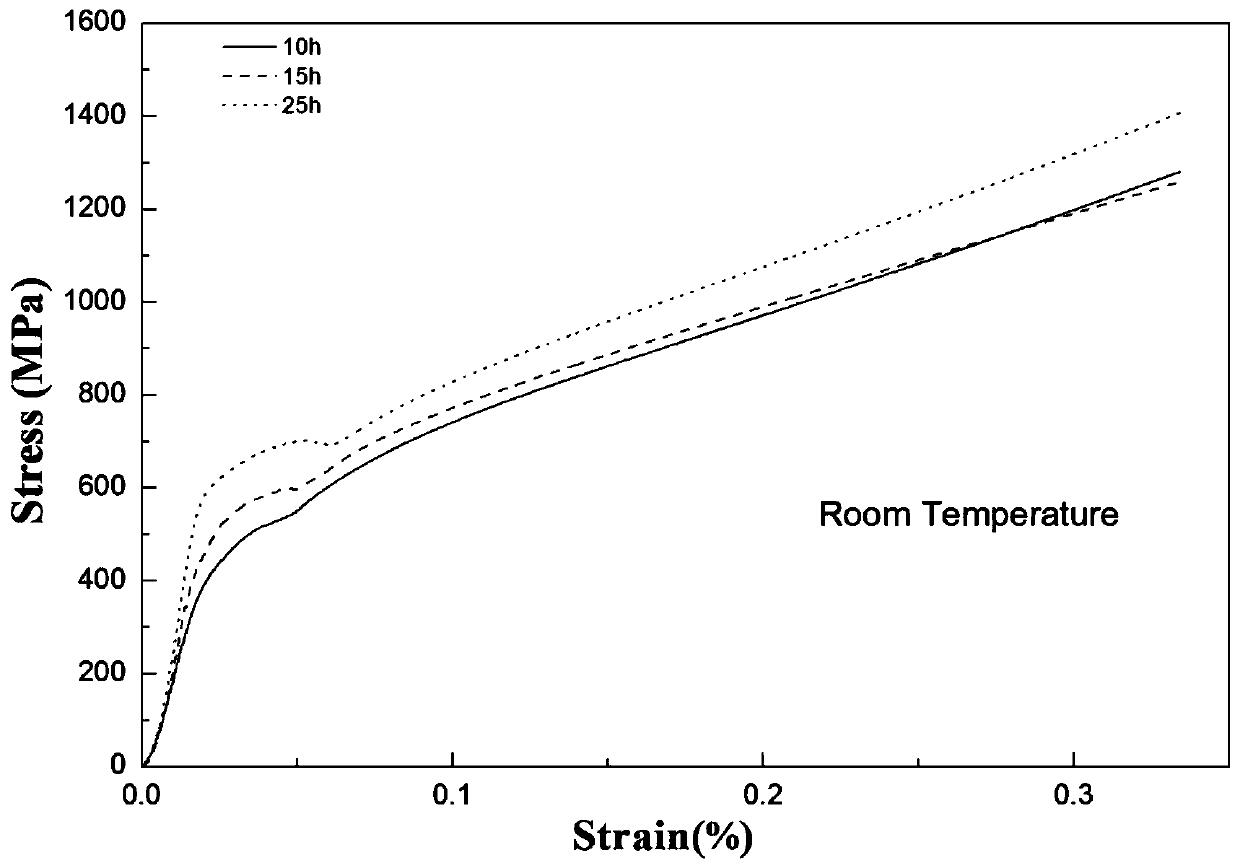

Embodiment 1

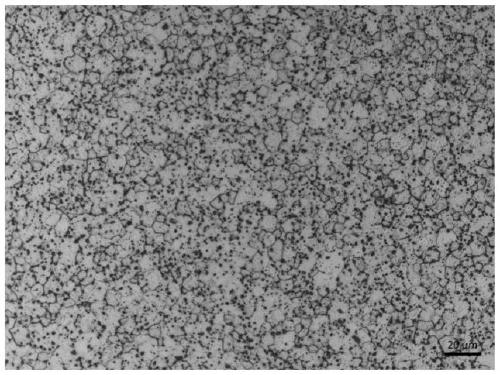

[0025] In this embodiment, the Mo-Ti-Zr-CNT molybdenum alloy composite material is doped with carbon nanotubes as a carbon source, wherein each component is constituted by mass ratio as follows: Ti 0.5%, Zr 0.1 %, CNT 0.03%, the balance is Mo.

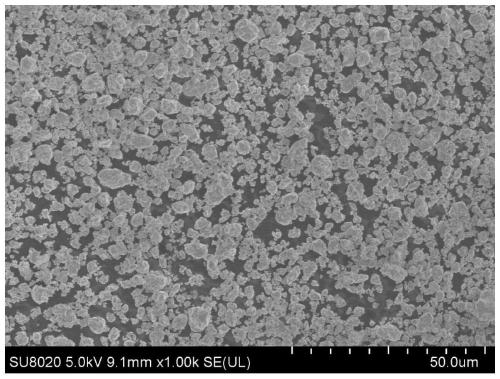

[0026] The original powder particle size is: TiH 2 Powder particle size is 30-40 microns, ZrH 2 The particle size of the powder is 30-50 microns, the particle size of the multi-wall CNT powder is 30-50 nanometers, and the particle size of the molybdenum powder is 3-5 microns.

[0027] The preparation method of high-strength Mo-Ti-Zr-CNT molybdenum alloy composite material in the present embodiment comprises the following steps:

[0028] 1. Powder mixing: According to the doping ratio, weigh 29.811g molybdenum powder, 0.156g TiH 2 Powder, 0.031g ZrH 2 powder and 0.009g of carbon nanotube powder were placed in a mixing tank, and placed in a three-dimensional powder mixer for powder mixing for 2 hours.

[0029] 2. Ball milling: Put t...

Embodiment 2

[0033] In this embodiment, the Mo-Ti-Zr-CNT molybdenum alloy composite material is doped with carbon nanotubes as a carbon source, wherein each component is constituted by mass ratio as follows: Ti 0.5%, Zr 0.1 %, CNT 0.03%, the balance is Mo.

[0034] The original powder particle size is: TiH 2 Powder particle size is 30-40 microns, ZrH 2 The particle size of the powder is 30-50 microns, the particle size of the multi-wall CNT powder is 30-50 nanometers, and the particle size of the molybdenum powder is 3-5 microns.

[0035] The preparation method of high-strength Mo-Ti-Zr-CNT molybdenum alloy composite material in the present embodiment comprises the following steps:

[0036] 1. Powder mixing: According to the doping ratio, weigh 49.685g molybdenum powder, 0.26g TiH 2 Powder, 0.051g ZrH 2 powder and 0.015g of carbon nanotube powder were placed in a mixing tank, and placed in a three-dimensional powder mixer for powder mixing for 2 hours.

[0037] 2. Ball milling: put th...

Embodiment 3

[0041] In this embodiment, the Mo-Ti-Zr-CNT molybdenum alloy composite material is doped with carbon nanotubes as a carbon source, wherein each component is constituted by mass ratio as follows: Ti 0.5%, Zr 0.1 %, CNT 0.03%, the balance is Mo.

[0042] The original powder particle size is: TiH 2 Powder particle size is 30-40 microns, ZrH 2 The particle size of the powder is 30-50 microns, the particle size of the multi-wall CNT powder is 30-50 nanometers, and the particle size of the molybdenum powder is 3-5 microns.

[0043] The preparation method of high-strength Mo-Ti-Zr-CNT molybdenum alloy composite material in the present embodiment comprises the following steps:

[0044] 1. Powder mixing: According to the doping ratio, weigh 49.685g molybdenum powder, 0.26g TiH 2 Powder, 0.051g ZrH 2 powder and 0.015g of carbon nanotube powder were placed in a mixing tank, and placed in a three-dimensional powder mixer for powder mixing for 2 hours.

[0045] 2. Ball milling: put th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com