Preparation method of ultra-pure high-activity battery-grade lithium fluoride

A lithium fluoride, battery-grade technology, applied in the field of preparation of ultra-pure and high-activity battery-grade lithium fluoride, can solve the problems of insufficient material purity, unstable lithium fluoride activity, affecting the purity of LiPF6 materials, and achieve low energy consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

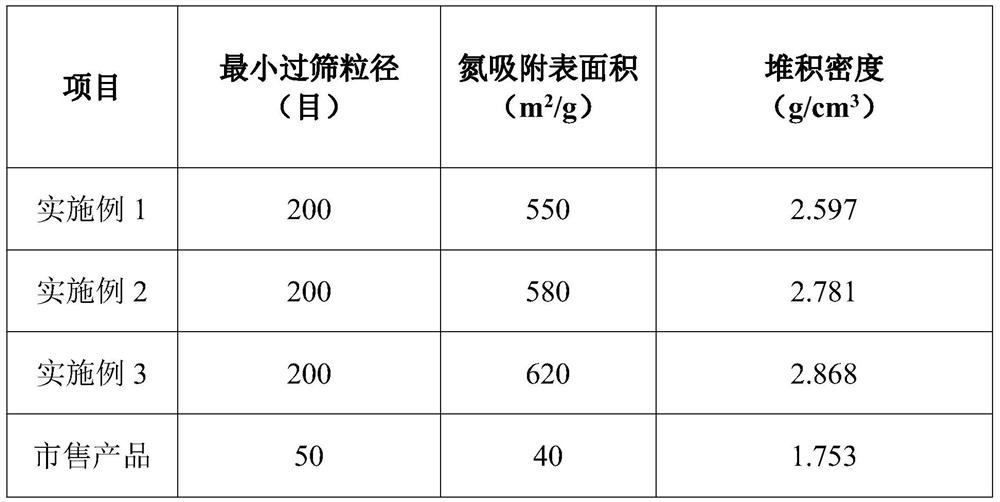

Examples

preparation example Construction

[0031] A method for preparing ultra-pure and highly active battery-grade lithium fluoride, the method comprising the following steps:

[0032] Step 1, using ultrapure water to prepare anhydrous hydrogen fluoride into aqueous hydrofluoric acid, and blending the aqueous hydrofluoric acid and crude lithium fluoride into lithium fluoride slurry;

[0033] Step 2. Under continuous stirring, the lithium fluoride slurry is continuously fed into a ball mill for ball milling. The temperature of the suspension in the ball mill is 50-100 degrees Celsius. After the materials in the ball mill are dissolved, filter the eluate , washing to obtain high-quality hydrogen fluoride microcrystals;

[0034] Step 3, adding the refined hydrogen fluoride microcrystals into anhydrous hydrogen fluoride, dissolving at 10-15 degrees Celsius for 10-30 minutes, and filtering to obtain a clear lithium hydrogen fluoride solution;

[0035] Step 4, cooling and crystallizing the lithium hydrogen fluoride solutio...

Embodiment 1

[0047] A method for preparing ultra-pure and highly active battery-grade lithium fluoride, the method comprising the following steps:

[0048] Step 1, using ultrapure water to deploy anhydrous hydrogen fluoride into hydrofluoric acid with water, and blend the hydrofluoric acid with water and crude lithium fluoride into lithium fluoride slurry; the mass percentage of hydrofluoric acid with water The concentration is 25%, and the ambient temperature is 0 degrees Celsius during deployment.

[0049] Step 2. Under continuous stirring, continuously send the lithium fluoride slurry into a ball mill for ball milling. The temperature of the suspension in the ball mill is 80 degrees Celsius. After the materials in the ball mill are dissolved, filter and wash the solution , to obtain high-quality hydrogen fluoride microcrystals; the mass concentration of the eluate from the ball mill is 120mg / L.

[0050] Step 3, adding the refined hydrogen fluoride microcrystals into anhydrous hydrogen ...

Embodiment 2

[0054] A method for preparing ultra-pure and highly active battery-grade lithium fluoride, the method comprising the following steps:

[0055] Step 1, using ultrapure water to deploy anhydrous hydrogen fluoride into hydrofluoric acid with water, and blend the hydrofluoric acid with water and crude lithium fluoride into lithium fluoride slurry; the mass percentage of hydrofluoric acid with water The concentration is 5%, and the ambient temperature is 10 degrees Celsius during deployment.

[0056] Step 2. Under continuous stirring, continuously send the lithium fluoride slurry into a ball mill for ball milling. The temperature of the suspension in the ball mill is 100 degrees Celsius. After the materials in the ball mill are dissolved, filter and wash the solution , to obtain high-quality hydrogen fluoride microcrystals; the mass concentration of the eluate from the ball mill is 80mg / L.

[0057] Step 3: Add the refined hydrogen fluoride microcrystals into anhydrous hydrogen flu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com