Composite fuel additive

A composite, fuel technology, applied in the directions of fuel additives, fuels, liquid carbon-containing fuels, etc., can solve problems such as unsatisfactory effects, reduce the generation of harmful gases and black smoke, reduce sulfur trioxide content, and reduce emissions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

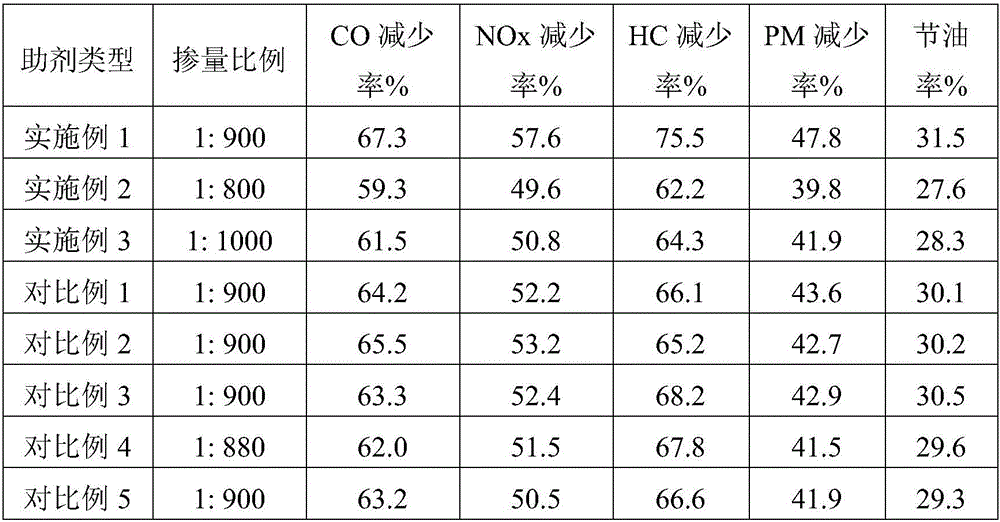

Examples

Embodiment 1

[0021] A composite fuel additive, made of the following components in parts by weight: 4 parts of isopropanol, 3 parts of tert-butanol, 2 parts of n-octanol, 2 parts of tert-amyl methyl ether, propylene 3 parts of dimethyl acid, 2 parts of pentyl nitrate, 12 parts of butyl acetate, 0.7 parts of dibutyl phthalate, 2 parts of strontium peroxide, 0.5 parts of ethyl acetate, 4 parts of fatty alcohol polyoxyethylene ether, 0.4 parts of nonylphenol polyoxyethylene ether, 0.5 parts of fluorocarbon surfactant, 0.3 parts of sodium carboxymethyl cellulose, 2 parts of polytetrafluoroethylene, 0.7 parts of catalyst, 0.2 parts of attapulgite powder, 2 parts of nano-cerium oxide , 0.3 parts of nano magnesium powder.

[0022] The catalyst is made of 3 parts of perovskite catalyst and 2 parts of spinel catalyst, wherein the perovskite catalyst is made of 2 parts of La 0.8 Sr 0.2 MnO 3 , 2 parts La 0.9 Na 0.1 Co 0.5 Mn 0.5 O 3 , 2 parts La 0.6 Ba 0.4 Co 0.2 Fe 0.8 O 3 , 5 parts LaFeO 3 Made; spin...

Embodiment 2

[0031] A composite fuel additive, made of the following components in parts by weight: 3 parts of isopropanol, 2 parts of tert-butanol, 1 part of n-octanol, 1 part of tert-amyl methyl ether, propylene 2 parts of dimethyl acid, 1 part of pentyl nitrate, 10 parts of butyl acetate, 0.6 parts of dibutyl phthalate, 1 part of strontium peroxide, 0.4 parts of ethyl acetate, 2 parts of fatty alcohol polyoxyethylene ether, 0.2 part of nonylphenol polyoxyethylene ether, 0.3 part of fluorocarbon surfactant, 0.2 part of sodium carboxymethyl cellulose, 1 part of polytetrafluoroethylene, 0.5 part of catalyst, 0.1 part of attapulgite powder, 1 part of nano-cerium oxide , 0.2 parts of nano magnesium powder.

[0032] The catalyst is made of 2 parts of perovskite catalyst and 1 part of spinel catalyst, wherein the perovskite catalyst is made of 1 part of La 0.8 Sr 0.2 MnO 3 , 1 part La 0.9 Na 0.1 Co 0.5 Mn 0.5 O 3 , 1 part La 0.6 Ba 0.4 Co 0.2 Fe 0.8 O 3 , 4 parts LaFeO 3 Made; spinel catalyst is ...

Embodiment 3

[0041] A composite fuel additive, which is made of the following components in parts by weight: 5 parts of isopropanol, 4 parts of tert-butanol, 3 parts of n-octanol, 3 parts of tert-amyl methyl ether, propylene 5 parts of dimethyl acid, 4 parts of pentyl nitrate, 15 parts of butyl acetate, 0.8 parts of dibutyl phthalate, 3 parts of strontium peroxide, 0.6 parts of ethyl acetate, 6 parts of fatty alcohol polyoxyethylene ether, 0.6 parts of nonylphenol polyoxyethylene ether, 0.7 parts of fluorocarbon surfactant, 0.5 parts of sodium carboxymethyl cellulose, 4 parts of polytetrafluoroethylene, 0.9 parts of catalyst, 0.3 parts of attapulgite powder, 3 parts of nano-cerium oxide , 0.4 parts of nano magnesium powder.

[0042] The catalyst is made of 4 parts of perovskite catalyst and 3 parts of spinel catalyst, wherein the perovskite catalyst is made of 3 parts of La 0.8 Sr 0.2 MnO 3 , 3 parts La 0.9 Na 0.1 Co 0.5 Mn 0.5 O 3 , 3 parts La 0.6 Ba 0.4 Co 0.2 Fe 0.8 O 3 , 6 parts LaFeO 3 M...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com