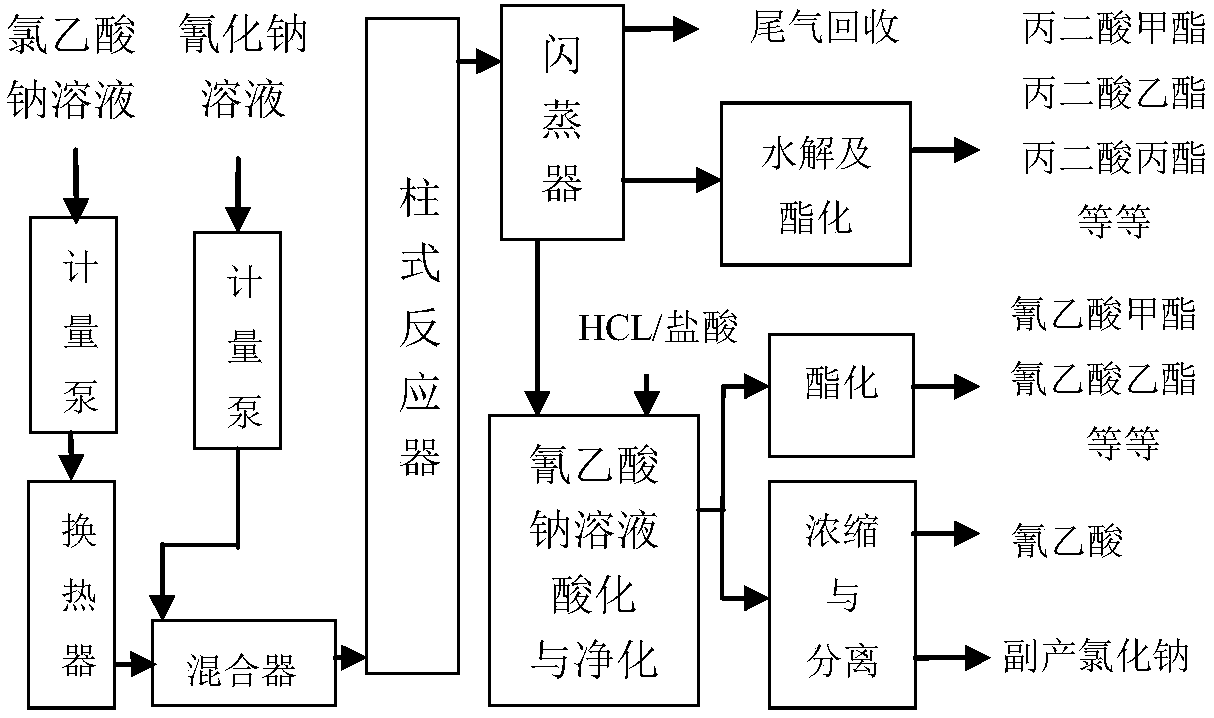

Environment-friendly and clean method for continuous cyaniding synthesis of sodium cyanoacetate and derivatives thereof

A technology for synthesizing sodium cyanoacetate and sodium cyanoacetate, which is applied in the preparation of organic compounds, cyanide reaction preparation, chemical instruments and methods, etc., to achieve the effects of increasing cyanide yield, saving production costs, and increasing product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1: 30.5% sodium chloroacetate aqueous solution with the speed of 100kg / min and 30.0% sodium cyanide aqueous solution with the speed of 44.9kg / min respectively with liquid metering continuous feeding pump from the head end of static mixer Injection, the sodium chloroacetate solution is preheated to 50°C through a heat exchanger before entering the mixer, the preheated sodium chloroacetate solution and the normal temperature sodium cyanide solution are fully mixed in the mixer and then flow into the column reactor, the mixed solution The temperature at the bottom of the column reactor is 68°C, the cyanation reaction material continuously enters and rises and undergoes rapid cyanation reaction. The temperature in the middle of the column reactor is 110°C, and the upper temperature of the column reactor is 115°C. The material reacts completely in the column reactor and flows out from the upper outlet; the retention time of the cyanide reaction material in the colu...

Embodiment 2

[0032]Example 2: 30.5% aqueous sodium chloroacetate solution at a rate of 200 kg / min and a 30.0% aqueous sodium cyanide solution at a rate of 89.8 kg / min were continuously fed from the head end of the static mixer with a liquid metering continuous feed pump. Injection, the sodium chloroacetate solution is preheated to 48 ℃ through the heat exchanger before entering the mixer, the preheated sodium chloroacetate solution and the normal temperature sodium cyanide solution are fully mixed in the mixer and then flow into the column reactor, the mixed solution The temperature at the bottom of the column reactor is 67°C, the cyanation reaction material continuously enters and rises and reacts rapidly, the temperature in the middle of the column reactor is 109°C, and the upper temperature of the column reactor is 115°C, and the cyanation reaction The material reacted completely in the column reactor and flowed out from the upper outlet; the retention time of the cyanation reaction mate...

Embodiment 3

[0035] Example 3: The 30.5% aqueous sodium chloroacetate solution was continuously fed from the head end of the static mixer at a rate of 150 kg / min and a 30.0% aqueous solution of sodium cyanide at a rate of 67.3 kg / min, respectively, with a liquid metering continuous feed pump. Injection, the sodium chloroacetate solution is preheated to 49 ℃ through the heat exchanger before entering the mixer, the preheated sodium chloroacetate solution and the normal temperature sodium cyanide solution are fully mixed in the mixer and then flow into the column reactor, the mixed solution The temperature at the bottom of the column reactor is 68°C, the cyanation reaction material continuously enters and rises and reacts rapidly, the temperature in the middle of the column reactor is 110°C, and the temperature at the upper part of the column reactor is 115°C, and the cyanation reaction The material reacted completely in the column reactor and flowed out from the upper outlet; the retention t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com