Polyurethane rubber plate type support production line and production method thereof

A polyurethane rubber and production line technology, applied in coatings and other directions, can solve the problems of difficult to place industry quality supervision, short service life of bearings, weak anti-aging ability, etc., to ensure traceability, reduce production energy consumption, and achieve finished products. high quality effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

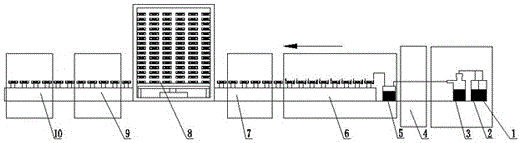

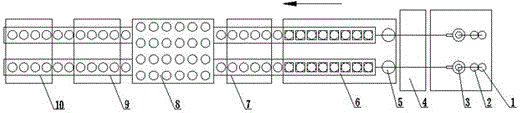

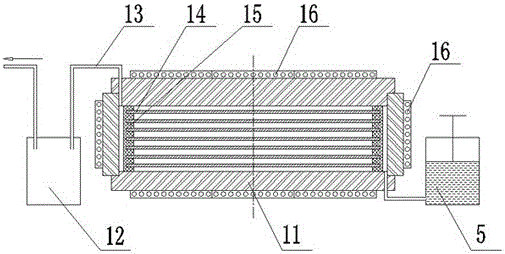

[0028] Below in conjunction with accompanying drawing this design is described in detail:

[0029] see figure 1 — image 3 : A polyurethane rubber plate support production line, including a fully automatic vacuum batching machine 3, a rubber material inspection machine 4, a fully automatic injection machine 5, a model pouring unit 6, a coding device 7 and a heat preservation and curing device 8 connected in sequence;

[0030] The full-automatic vacuum batching machine 3 is respectively connected with the group A distribution tank 1 and the B group distribution tank 2, the A component is polyether polyol, and the B component is isocyanate.

[0031] The mold pouring unit 6 includes a mold 11 and a vacuum collection bucket 12, the mold 11 is connected with the vacuum collection bucket 12 through a delivery pipe 13, the mold 11 includes a rectangular cavity, and two The sides are respectively provided with symmetrical prepolymer positioning blocks 15, and the prepolymer position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com