Composite polyurethane modifier for road asphalt

A composite polyurethane and road asphalt technology is applied in the field of road asphalt modifiers to meet paving requirements, prolong service life and achieve good storage stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The formula of composite polyurethane modifier is as follows: 60 parts by weight of the NCO-terminated prepolymer obtained by the reaction of diphenylmethane diisocyanate and vegetable oil polyol (referring to the embodiment 3 of CN101386563A), 35 parts by weight of The polymer polyol (Bayer company Arol 24-32) of average molecular weight 3500, the bismuth isooctanoate of 0.8 weight part, the aminopropyltrimethoxysilane of 3 weight parts, the sebacic acid of 1.2 weight part, wherein the pre The free NCO groups of the polymer are in excess of 220 mol % relative to the active hydrogen of the hydroxyl + amino + carboxylic acid groups in the polymer polyol + aminopropyltrimethoxysilane + sebacic acid. Based on the total amount of modifier added as 25% by weight of the base asphalt, the modifier and No. 70 straight-run road asphalt were dispersed and mixed at 130°C for 2 hours, and the softening point of the modified asphalt was determined to be 63.7°C after aging and cooling...

Embodiment 2

[0037] The formula of composite polyurethane modifier is as follows: 55 parts by weight of the NCO-terminated prepolymer formed by the reaction of diphenylmethane diisocyanate and polyoxyethylene-polyoxypropylene copolyether polyol of weight average molecular weight 5500, 1 part by weight 1,4-butanediol, 15 parts by weight of polymer polyol (Bayer company Arol 24-32), 0.05 parts by weight of bismuth octoate, 3.95 parts by weight of anilinomethyltriethoxysilane, 25 parts by weight of adipic acid, where the free NCO groups of the NCO-terminated prepolymer are reactive relative to the hydroxyl + amino + carboxylic acid groups in 1,4-butanediol + aminomethyltrimethoxysilane + adipic acid The hydrogen excess is 335 mol%. Based on the total amount of modifier added as 15% by weight of the base asphalt, the modifier was dispersed and mixed with No. 70 straight-run road asphalt at 135°C for 2 hours. After aging and cooling to room temperature, the softening point of the modified aspha...

Embodiment 3

[0039] The formula of composite polyurethane modifier is as follows: 35 parts by weight of the NCO-terminated prepolymer formed by the reaction of toluene diisocyanate and polytetrahydrofuran-oxyalkylene copolyether with a weight average molecular weight of 1000, 1 part by weight of trimethylolpropane, 12 parts by weight of Bayer's Arol 24-32 polymer polyol, 15 parts by weight of polyoxyethylene-polyoxypropylene copolyetheramine of weight average molecular weight 4000, 0.1 parts by weight of bismuth octoate, 3.9 parts by weight of anilinomethyltriethyl Oxysilane, 32 parts by weight of adipic acid, 1 part by weight of o-phthalic diisocaprylic anhydride, wherein the free NCO groups of the NCO-terminated prepolymer are multivalent relative to the trimethylolpropane + Arol 24-32 polymer Alcohol+polyoxyethylene-polyoxypropylene copolyetheramine+anilinomethyltrimethoxysilane+adipic acid+hydroxyl group+amino group+carboxylic acid group+acid anhydride group contained in adipic anhydrid...

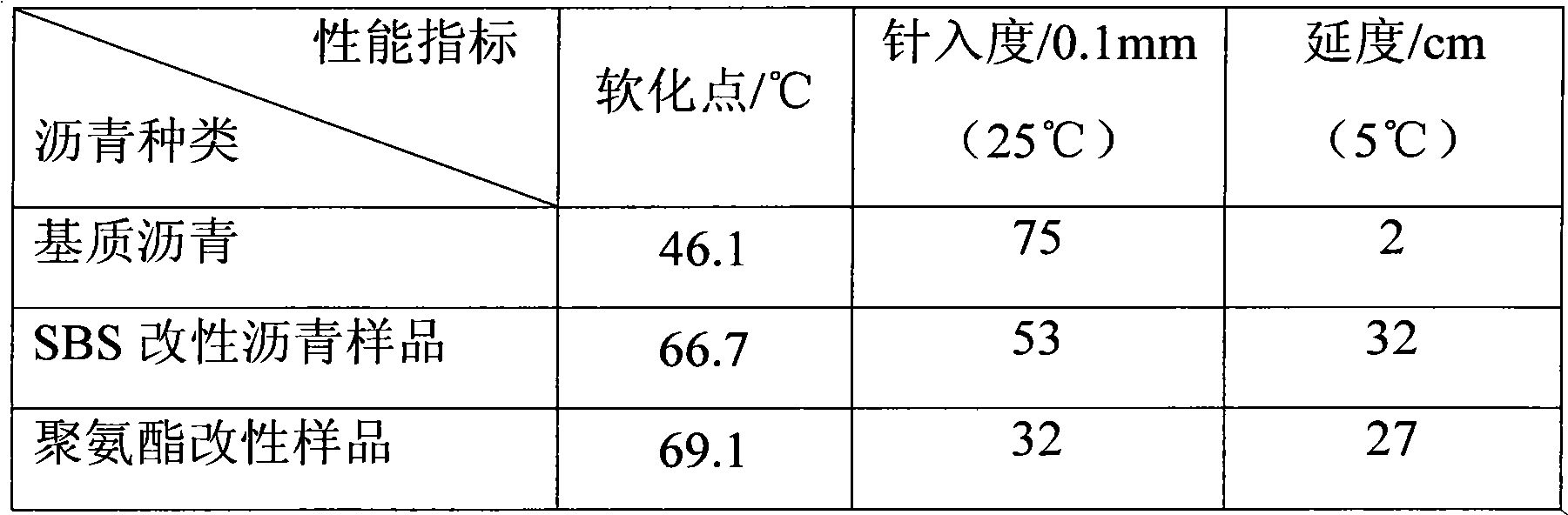

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com