Catalytic system for catalyzing decarbonylation of dimethyl oxalate to directly generate dimethyl carbonate

A technology for catalyzing dimethyl oxalate and dimethyl carbonate, which is applied in the preparation of carbonate/haloformate, catalyst activation/preparation, and preparation of organic compounds, to achieve innovative catalyst synthesis methods, good reactivity, and high selective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

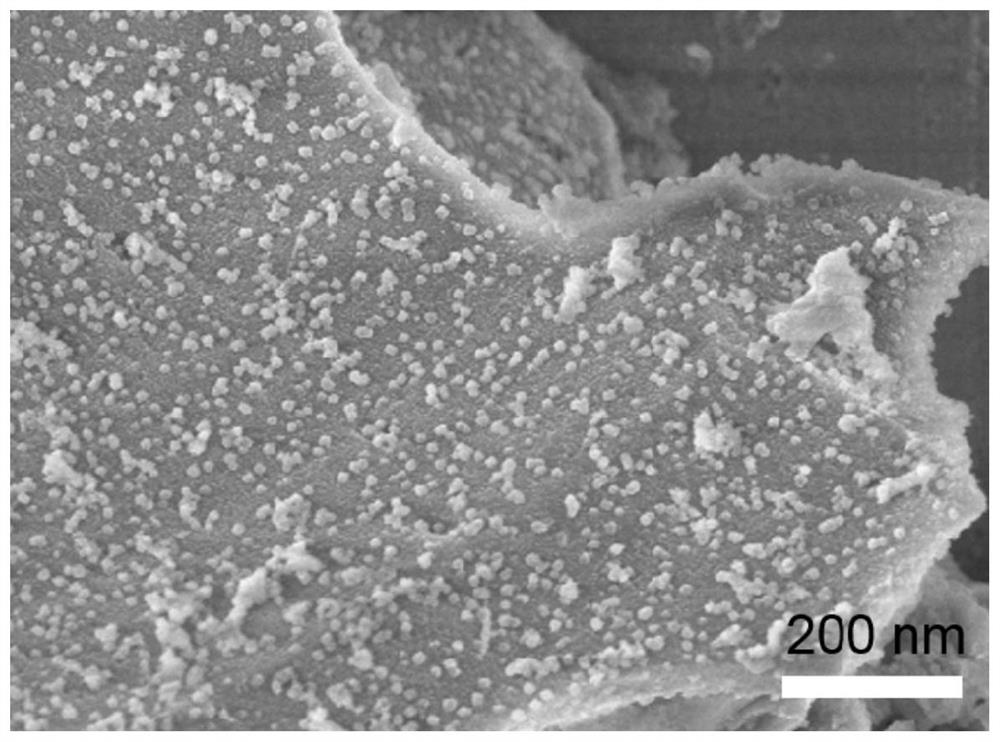

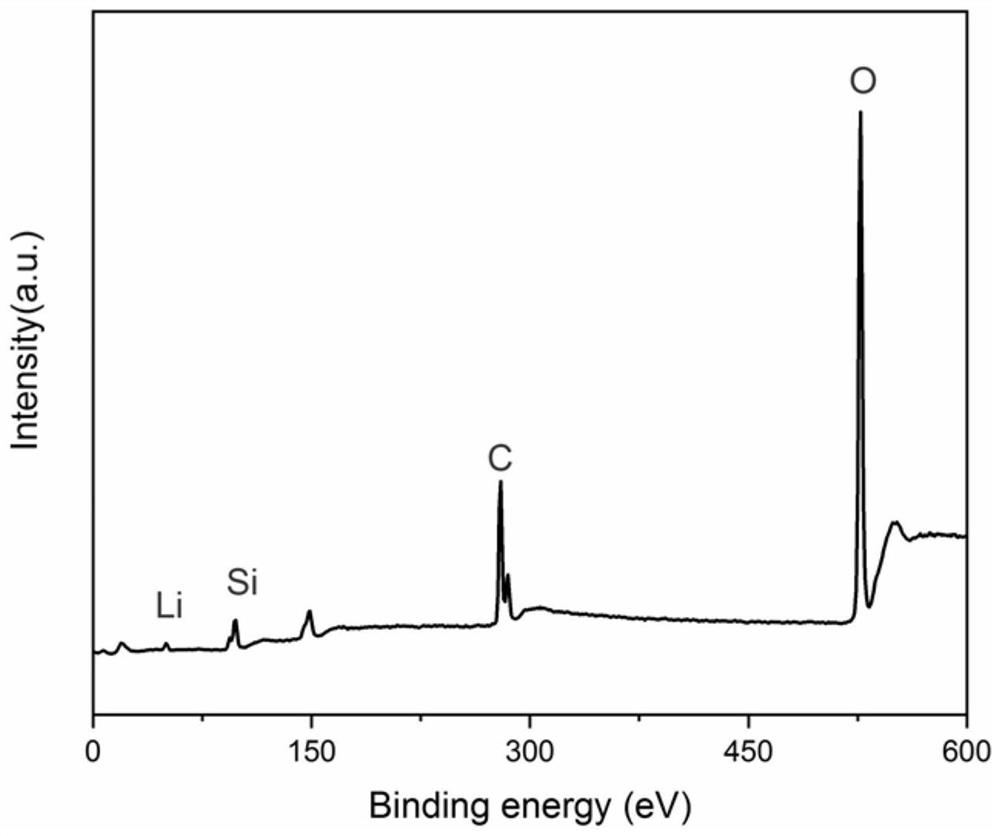

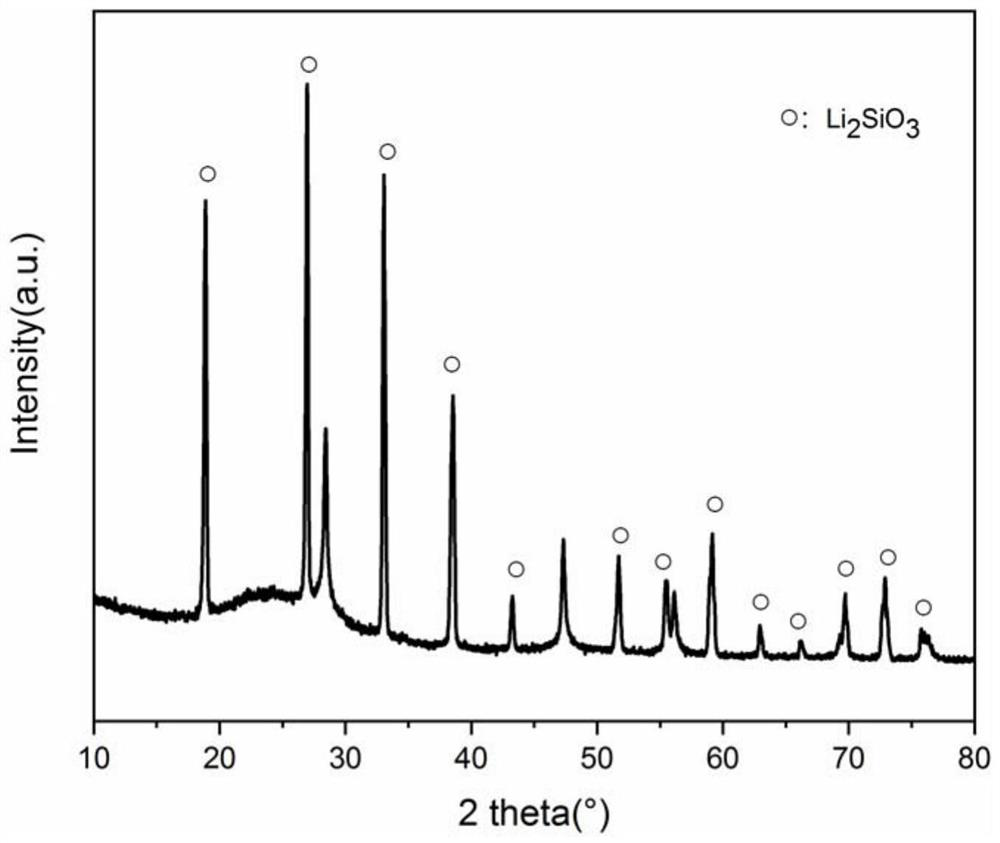

[0043] Preparation of Catalyst / Support Complex:

[0044] Dissolve 0.5g of lithium hydroxide and 0.2g of CTAB surfactant in 50mL of deionized water / ethanol (volume ratio 5:1) mixed solvent to form a uniform solution, and then 5g of the specific surface area is 500m 2 / g of nanoporous silica dispersed in the solution, fully impregnated, heated, stirred and dried, and then calcined the obtained solid at 800°C for 3 hours, and a chemical reaction occurred: 2LiOH+SiO 2 = Li 2 SiO 3 +H 2 O, making lithium silicate (Li 2 SiO 3 ) catalyst to obtain a catalyst / support composite.

[0045] Application of catalyst / support complex to catalyze the decarbonylation reaction of dimethyl oxalate:

[0046] Put 5g of the above-prepared catalyst / carrier complex and 500mL of ethylene glycol solvent into a stainless steel autoclave, add 500mL dimethyl oxalate (574g) after preheating to 100°C, seal the autoclave and heat it in an oil bath while stirring To 150°C, argon gas was introduced to ma...

Embodiment 2

[0051] Preparation of Catalyst / Support Complex:

[0052] Dissolve 0.5g of sodium oxalate and 0.2g of SDBS surfactant in 50mL of deionized water / ethanol (volume ratio 5:1) mixed solvent to form a uniform solution; using a specific surface area of 800m 2 / g of porous activated carbon was soaked and adsorbed tetraethyl silicate for 1 h, and after taking it out, it was pyrolyzed under argon to obtain activated carbon coated with a silicon dioxide layer. Disperse 5 g of the above-mentioned activated carbon coated with silica layer in sodium oxalate solution, fully impregnate it, heat, stir and dry it, then calcinate the obtained solid at 800°C for 3 hours, and a chemical reaction occurs: Na 2 C 2 o 4 +SiO2 2 →Na 2 SiO 3 +CO+CO 2 , making sodium silicate (Na 2 SiO 3 )catalyst.

[0053] Application of catalyst / support complex to catalyze the decarbonylation reaction of dimethyl oxalate:

[0054] Put 5g of the above-prepared catalyst / carrier complex and 500mL of ethylene g...

Embodiment 3

[0059] Preparation of Catalyst / Support Complex:

[0060] Dissolve 0.8g potassium acetate and 0.2g CTAB surfactant in 50mL deionized water / ethanol (volume ratio 5:1) mixed solvent to form a homogeneous solution. Utilize a specific surface area of 500m 2 / g of porous activated carbon was soaked and adsorbed ethyl orthogermanate for 3 hours, and after taking it out, it was pyrolyzed at high temperature under argon to obtain activated carbon coated with a germanium dioxide layer. Disperse 5 g of the above-mentioned activated carbon coated with germanium dioxide layer in potassium acetate solution, fully impregnate it, heat, stir and dry it, and then calcinate the obtained solid at 800 ° C for 3 hours, and a chemical reaction occurs: CH 3 COOK+GeO 2 →K 2 GeO 3 +H 2 O+CO 2 , making potassium germanate (K 2 GeO 3 )catalyst.

[0061] Applied to catalyze the decarbonylation reaction of dimethyl oxalate:

[0062] Put 5g of the catalyst / carrier compound prepared above and 500...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com