Microemulsion polymerization strong coater for drilling fluid and preparation method of strong coater

A microemulsion polymerization and drilling fluid technology, applied in the field of oilfield chemical treatment agents, can solve the problems of unfavorable industrial production, expensive raw materials, complicated preparation steps, etc., and achieve the effects of excellent anti-slump effect, fast dissolution rate, and narrow molecular weight distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

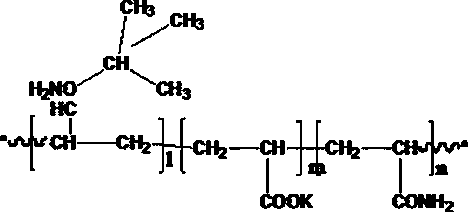

Image

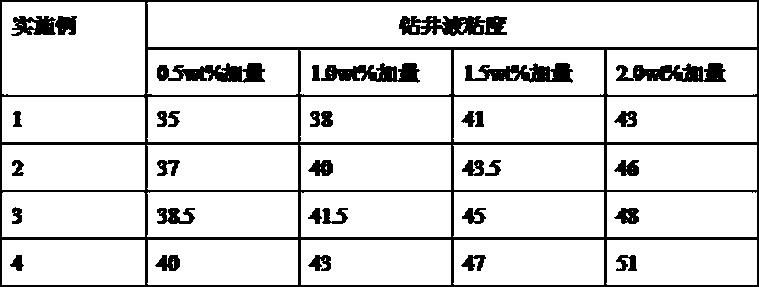

Examples

Embodiment 1

[0013] (1) In the reactor, add deionized water and 60kg potassium hydroxide, start stirring, wait until the potassium hydroxide is completely dissolved, and after cooling to below 40°C, add 2-acrylamide- Add 2-methylpropanesulfonic acid and acrylic acid to the above solution until pH=7-9, after cooling to room temperature, add 180kg of acrylamide and 20kg of complexing agent disodium edetate, stir and mix well; (2) in Add 200kg of white oil and 10kg of emulsifier Span-80 into the emulsification reaction kettle, turn on the high-speed agitator, emulsify for 30 minutes, and bubble high-purity nitrogen for 20 minutes, and continue to stir at a high speed. The temperature is controlled below 40°C; (3) in nitrogen Add the reaction product in step (1) into the emulsification reactor under protection, stir at high speed for 60 minutes, add 8g of initiator hydrogen peroxide, slow down the stirring speed, and start to slowly increase the temperature of the reactor to 65-68°C; (4 ) to r...

Embodiment 2

[0015] (1) In the reactor, add deionized water and 80kg potassium hydroxide, start stirring, wait until the potassium hydroxide is completely dissolved, and after cooling to below 40°C, add 2-acrylamide- Add 2-methylpropanesulfonic acid and acrylic acid to the above solution until pH=7-9, after cooling to room temperature, add 200kg of acrylamide and 20kg of complexing agent disodium edetate, stir and mix well; (2) in Add 300kg of white oil and 20kg of emulsifier Span-80 into the emulsification reaction kettle, turn on the high-speed agitator, emulsify for 30 minutes, and bubble high-purity nitrogen for 20 minutes, and continue to stir at a high speed. The temperature is controlled below 40°C; (3) in nitrogen Add the reaction product in step (1) into the emulsification reactor under protection, stir at high speed for 60 minutes, add 10g of initiator hydrogen peroxide, slow down the stirring speed, and start to slowly increase the temperature of the reactor to 65-68°C; (4 )...

Embodiment 3

[0017] (1) In the reactor, add deionized water and 100kg potassium hydroxide, start stirring, wait until the potassium hydroxide is completely dissolved, and after cooling to below 40°C, add 2-acrylamide- Add 2-methylpropanesulfonic acid and acrylic acid to the above solution until the pH=7-9. After cooling to room temperature, add 240kg of acrylamide and 20kg of complexing agent disodium ethylenediaminetetraacetic acid, stir and mix evenly; (2) Add 350kg of white oil and 20kg of emulsifier Span-80 into the emulsification reaction kettle, turn on the high-speed agitator, emulsify for 30 minutes, and bubble high-purity nitrogen for 20 minutes, and continue to stir at a high speed. The temperature is controlled below 40°C; (3) In nitrogen Add the reaction product in step (1) into the emulsification reactor under protection, stir at high speed for 60 minutes, add 15g of initiator hydrogen peroxide, slow down the stirring speed, and start to slowly increase the temperature of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com