Composition for anti-collapse drilling fluid capable of reducing collapse pressure, anti-collapse drilling fluid and anti-collapse method

A drilling fluid and composition technology, applied in the field of anti-collapse drilling fluid composition, which can solve problems such as changes in rock stress distribution, deterioration, and increase in rock pore pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

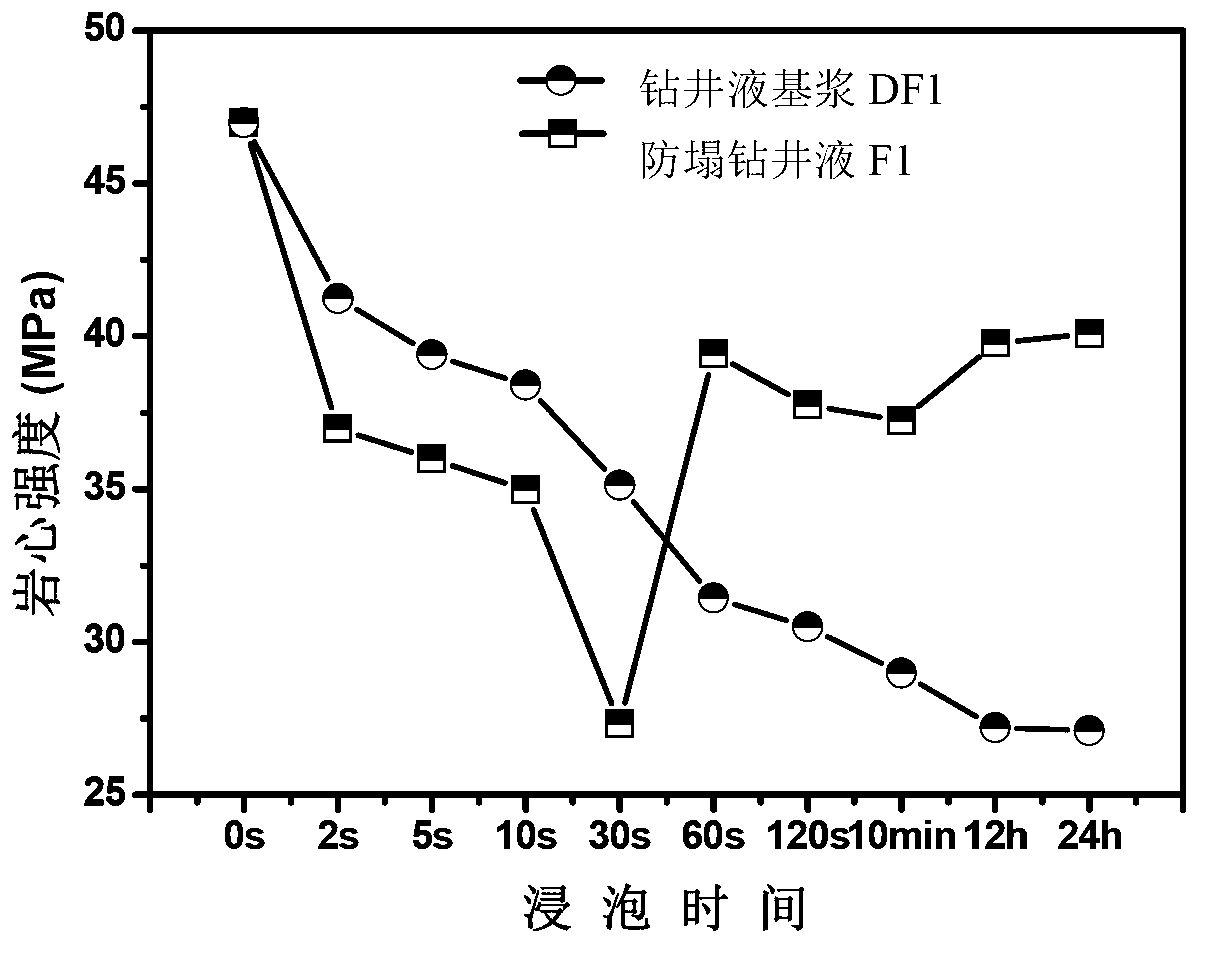

Examples

preparation example 1

[0038] This preparation example is used to illustrate the preparation of the wetting reversal agent provided by the present invention.

[0039] Add 0.01g of sodium dodecylsulfonate and 25mL of water into a four-necked flask equipped with an electric stirrer, a reflux condenser and a thermometer, and control the temperature at 40°C to stir and mix well, then slowly add the well-mixed A mixture of 3g styrene, 3.5g butyl acrylate and 3.5g methacrylic acid, after emulsification for 0.1 hour, the temperature was raised to 80°C, then 0.01g potassium persulfate was added and reacted for 6 hours, then the obtained emulsion containing copolymer was cooled Bring to room temperature 25°C and add 2g of ammonium sulfate to stir the copolymer to coagulate and filter to obtain 10g of copolymer (referred to as RFJ-1), wherein the number average molecular weight of the copolymer is 1000.

preparation example 2

[0041] This preparation example is used to illustrate the preparation of the wetting reversal agent provided by the present invention.

[0042] Add 0.5g of sodium dodecylsulfonate and 25mL of water into a four-neck flask equipped with an electric stirrer, a reflux condenser and a thermometer, and control the temperature at 30°C to stir and mix well, then slowly add the well-mixed The mixture of 2.5g styrene, 4.5g butyl acrylate and 3g methacrylic acid was emulsified for 0.5 hours and the temperature was raised to 95°C, then 0.002g potassium persulfate was added and reacted for 2 hours, then the emulsion containing the copolymer was cooled Bring to room temperature 25°C and add 2g of ammonium sulfate to stir the copolymer to coagulate and filter to obtain 9.8g of copolymer (referred to as RFJ-2), wherein the number average molecular weight of the copolymer is 5000.

preparation example 3

[0044] This preparation example is used to illustrate the preparation of the wetting reversal agent provided by the present invention.

[0045] Add 0.2g of sodium dodecylsulfonate and 25mL of water into a four-necked flask equipped with an electric stirrer, a reflux condenser and a thermometer, and control the temperature at 35°C to stir and mix well, then slowly add the well-mixed The mixture of 4g styrene, 2.5g butyl acrylate and 3.5g methacrylic acid was emulsified for 0.5 hours and the temperature was raised to 85°C, then 0.005g potassium persulfate was added and reacted for 4 hours, then the emulsion containing the copolymer was cooled Bring to room temperature 25°C and add 2g of ammonium sulfate to stir the copolymer to coagulate and filter to obtain 9.9g of copolymer (referred to as RFJ-3), wherein the number average molecular weight of the copolymer is 2000.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com