Composition for anti-collapse drilling fluid capable of reducing collapse pressure, anti-collapse drilling fluid and anti-collapse method

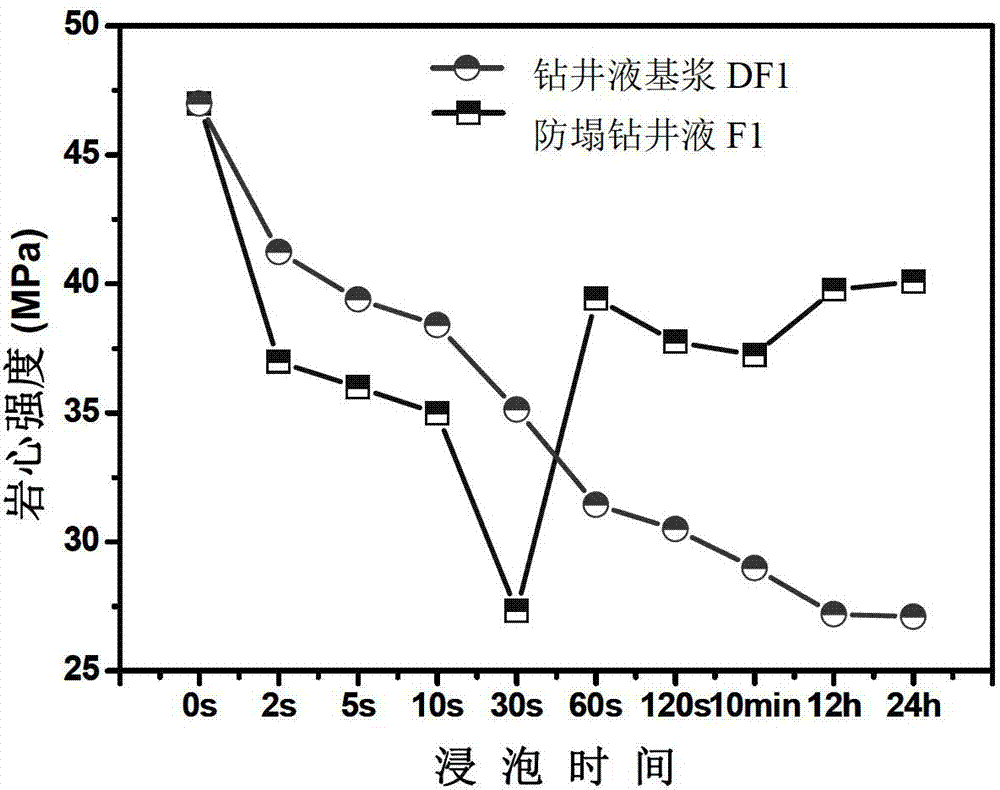

A drilling fluid and composition technology, applied in the field of anti-slump drilling fluid compositions, can solve the problems of rock stress distribution change, deterioration, increase in rock void pressure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0038] This preparation example is used to illustrate the preparation of the wetting reversal agent provided by the present invention.

[0039] Add 0.01g of sodium dodecylsulfonate and 25mL of water into a four-necked flask equipped with an electric stirrer, a reflux condenser and a thermometer, and control the temperature at 40°C to stir and mix well, then slowly add the well-mixed A mixture of 3g styrene, 3.5g butyl acrylate and 3.5g methacrylic acid, after emulsification for 0.1 hour, the temperature was raised to 80°C, then 0.01g potassium persulfate was added and reacted for 6 hours, then the obtained emulsion containing copolymer was cooled Bring to room temperature 25°C and add 2g of ammonium sulfate to stir the copolymer to coagulate and filter to obtain 10g of copolymer (referred to as RFJ-1), wherein the number average molecular weight of the copolymer is 1000.

preparation example 2

[0041] This preparation example is used to illustrate the preparation of the wetting reversal agent provided by the present invention.

[0042] Add 0.5g of sodium dodecylsulfonate and 25mL of water into a four-neck flask equipped with an electric stirrer, a reflux condenser and a thermometer, and control the temperature at 30°C to stir and mix well, then slowly add the well-mixed The mixture of 2.5g styrene, 4.5g butyl acrylate and 3g methacrylic acid was emulsified for 0.5 hours and the temperature was raised to 95°C, then 0.002g potassium persulfate was added and reacted for 2 hours, then the emulsion containing the copolymer was cooled Bring to room temperature 25°C and add 2g of ammonium sulfate to stir the copolymer to coagulate and filter to obtain 9.8g of copolymer (referred to as RFJ-2), wherein the number average molecular weight of the copolymer is 5000.

preparation example 3

[0044] This preparation example is used to illustrate the preparation of the wetting reversal agent provided by the present invention.

[0045] Add 0.2g of sodium dodecylsulfonate and 25mL of water into a four-necked flask equipped with an electric stirrer, a reflux condenser and a thermometer, and control the temperature at 35°C to stir and mix well, then slowly add the well-mixed The mixture of 4g styrene, 2.5g butyl acrylate and 3.5g methacrylic acid was emulsified for 0.5 hours and the temperature was raised to 85°C, then 0.005g potassium persulfate was added and reacted for 4 hours, then the emulsion containing the copolymer was cooled Bring to room temperature 25°C and add 2g of ammonium sulfate to stir the copolymer to coagulate and filter to obtain 9.9g of copolymer (referred to as RFJ-3), wherein the number average molecular weight of the copolymer is 2000.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com