A low energy consumption hydration air separation device and method

A technology of air separation and low energy consumption, applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of high pressure, harsh operating conditions, low operating temperature, etc., achieve good results, ease hydration conditions, reduce Effects of Hydration Stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

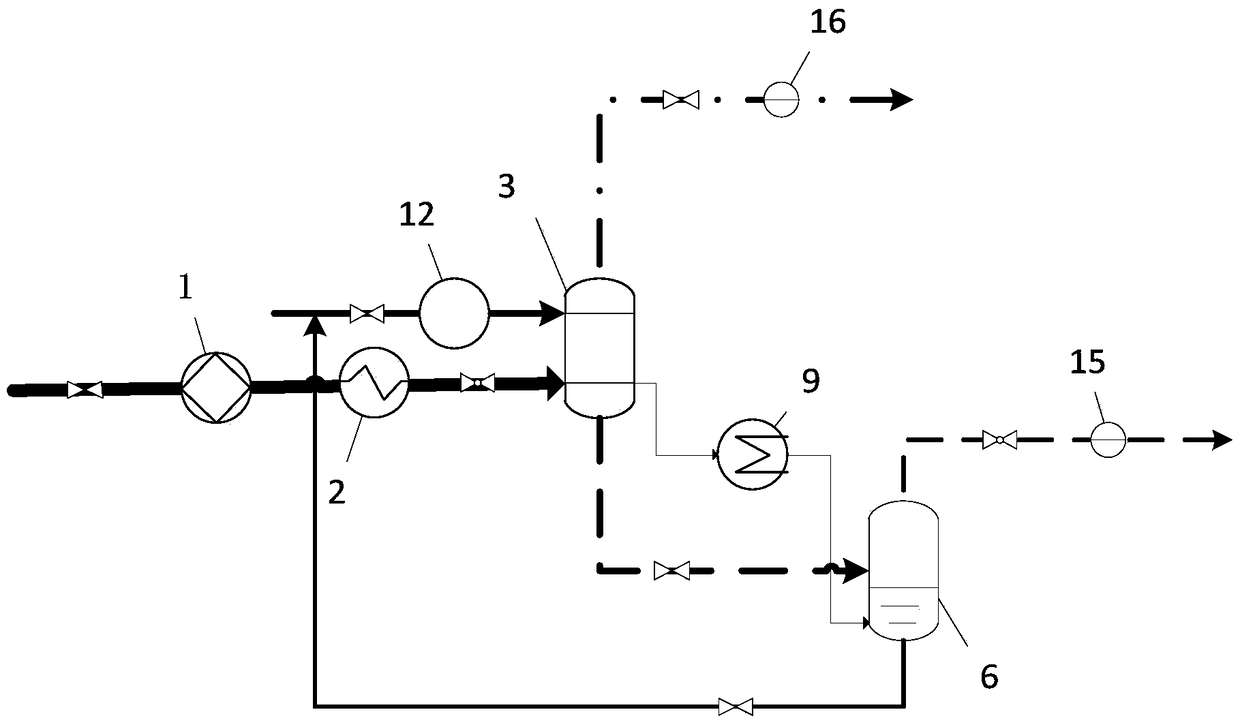

[0043] Example 1: Single-stage continuous hydration separation of air

[0044] Such as figure 1 As shown, a low-energy hydration air separation device includes a compressor 1, a precooling system 2, a first hydration tower 3, a first decomposition tower 6, a first heat pump 9, a first vacuum pump 12, and a first oxygen concentration detection Device 15 and the second oxygen concentration detector 16; Compressor 1 and precooling system 2 are connected by pipeline, and precooling system 2 communicates with the air inlet of the first hydration tower 3, and the liquid inlet of the first hydration tower 3 connects the first Vacuum pump 12, the hydrate solution output port of the first hydration tower 3 is connected with the feed port of the first decomposition tower 6, the raffinate output port of the first decomposition tower 6 is connected with the liquid inlet of the first hydration tower 3, the first hydration Tower 3 and the first decomposition tower 6 are also connected by t...

Embodiment 2

[0054] Embodiment 2: single-stage continuous hydration separation air (see figure 1 )

[0055] A kind of hydration air separation method comprises the steps:

[0056] 1) Clean the first hydration tower 3 and the first decomposition tower 6. The first hydration tower 3 and the first decomposing tower 6 are vacuumized, and the hydration accelerator and distilled water are added to the liquid inlet of the first hydration tower 3 by the first vacuum pump 12. The hydration accelerator is tetrabutylammonium fluoride TBAF (thermodynamically promoted agent) mass fraction x=0.35, sodium dodecyl sulfate SDS (kinetic accelerator) mass fraction x=0.05, distilled water is 500ml.

[0057] 2) The raw material is air (a binary mixed gas of 21mol% oxygen and 79mol% nitrogen), the air enters the first hydration tower 3 for hydration, and the temperature t of the compressed air entering the first hydration tower 3 is controlled 1 =32°C, pressure p 1 = 42.5 MPa. After the hydrate is formed, ...

Embodiment 3

[0060] Embodiment 3: single-stage batch hydration separation air (see figure 1 )

[0061] A method for separating hydrated air, comprising the steps of:

[0062] 1) Clean the first hydration tower 3 and the first decomposition tower 6. The first hydration tower 3 and the first decomposition tower 6 are vacuumized, and the hydration accelerator and distilled water are added to the liquid inlet of the first hydration tower 3 by the first vacuum pump 12. The hydration accelerator is tetrahydrofuran THF (thermodynamic accelerator) mass fraction x =0.165, distilled water is 500ml, operating conditions are:

[0063] 1) The raw material is air (a binary mixed gas of 21mol% oxygen and 79mol% nitrogen), and the air enters the first hydration tower 3 for hydration, and controls the temperature t of the compressed air entering the first hydration tower 3 1 =-0.5℃, pressure p 1 = 3.5 MPa. After the hydrate is formed (by increasing the gas-liquid mass transfer contact area, such as st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com