Modified polyanionic ammonium salt for drilling fluid and preparation method of modified polyanion ammonium salt

A polyanion and drilling fluid technology, applied in the fields of petroleum drilling aids and fluid loss reducers for drilling fluids, to achieve outstanding anti-slump effect, reduced fluid loss and good anti-slump effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

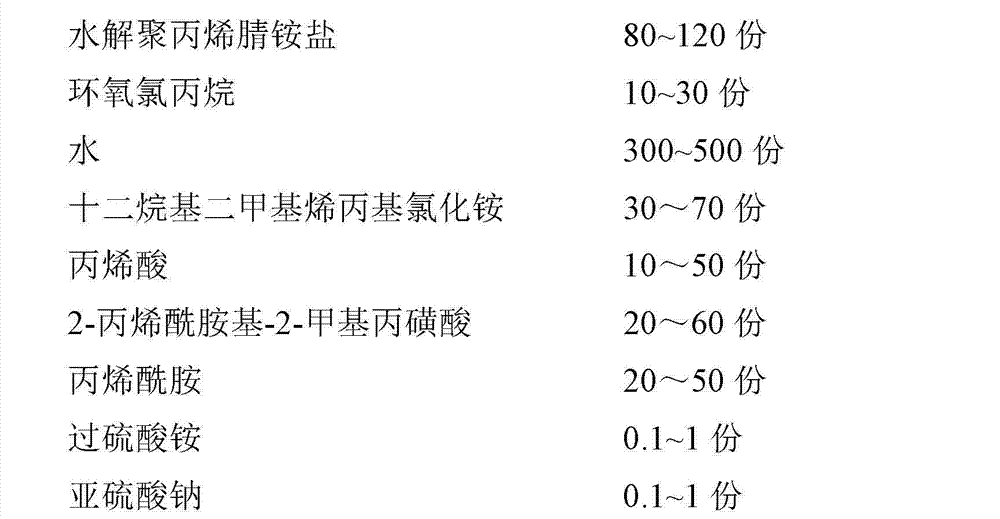

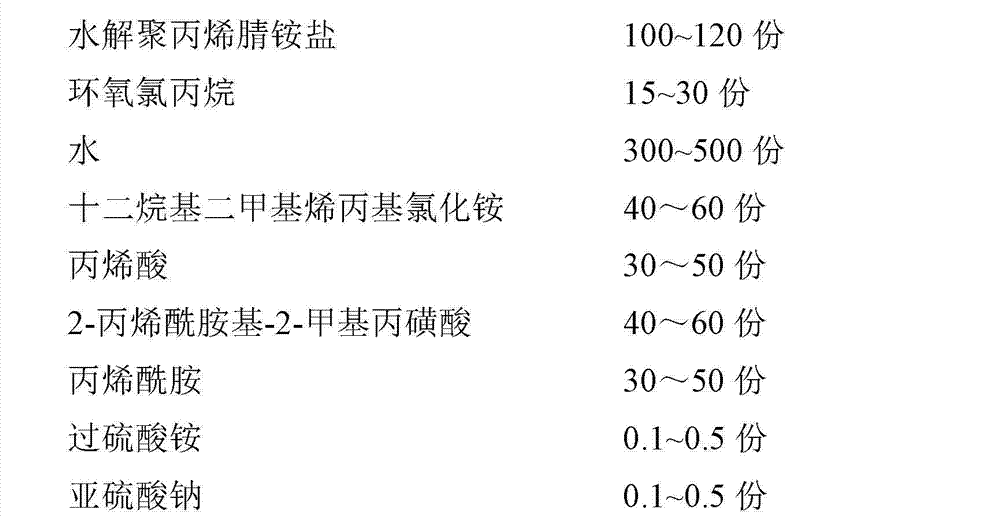

[0021] Embodiment 1: The modified polyanionic ammonium salt (i.e. fluid loss reducer) for drilling fluid of the present invention is made from the raw materials of the following weight ratio:

[0022] 120 kg of hydrolyzed polyacrylonitrile ammonium salt, 30 kg of epichlorohydrin, 300 kg of water, 60 kg of dodecyldimethylallyl ammonium chloride, 40 kg of acrylic acid, 2-acrylamido-2-methyl 60 kg of propanesulfonic acid, 40 kg of acrylamide, 0.3 kg of ammonium persulfate, and 0.2 kg of sodium sulfite.

[0023] The preparation method of the modified polyanion ammonium salt for drilling fluid comprises the following steps (sequentially): (1), weighing water, hydrolyzed polyacrylonitrile ammonium salt, epichlorohydrin, ten Dialkyl dimethyl allyl ammonium chloride, ammonium persulfate, and sodium sulfite are added to the stirred reactor, sealed, heated to 145-150°C (choose 145°C), and react for 2.5-3 hours (choose 3 hours), lower the temperature to below 60°C (55°C is optional); (2...

Embodiment 2

[0025] Embodiment 2: The modified polyanionic ammonium salt (i.e. fluid loss reducer) for drilling fluid of the present invention is made from the raw materials of the following weight ratio:

[0026] 80 kg of hydrolyzed polyacrylonitrile ammonium salt, 20 kg of epichlorohydrin, 300 kg of water, 30 kg of dodecyldimethylallyl ammonium chloride, 50 kg of acrylic acid, 2-acrylamido-2-methyl 40 kg of propanesulfonic acid, 20 kg of acrylamide, 0.1 kg of ammonium persulfate, and 0.1 kg of sodium sulfite.

[0027] Or it can be 120 kg of hydrolyzed polyacrylonitrile ammonium salt, 30 kg of epichlorohydrin, 500 kg of water, 70 kg of dodecyldimethylallyl ammonium chloride, 40 kg of acrylic acid, 2-acrylamido-2 - Methylpropanesulfonic acid 40 kg, acrylamide 50 kg, ammonium persulfate 1 kg, sodium sulfite 1 kg.

[0028] Or it can be 100 kg of hydrolyzed polyacrylonitrile ammonium salt, 10 kg of epichlorohydrin, 400 kg of water, 65 kg of dodecyldimethylallyl ammonium chloride, 10 kg of ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com