Integrated vertical cotton shaping bra and making method thereof

A technology for shaping bras and standing cotton, which is applied in the field of bras, can solve the problems of poor washing resistance and shaping effect of standing cotton, reduce bra gathering and shaping effect, and poor washing resistance of standing cotton, so as to improve the three-dimensional effect, Improve washing resistance and anti-slump effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

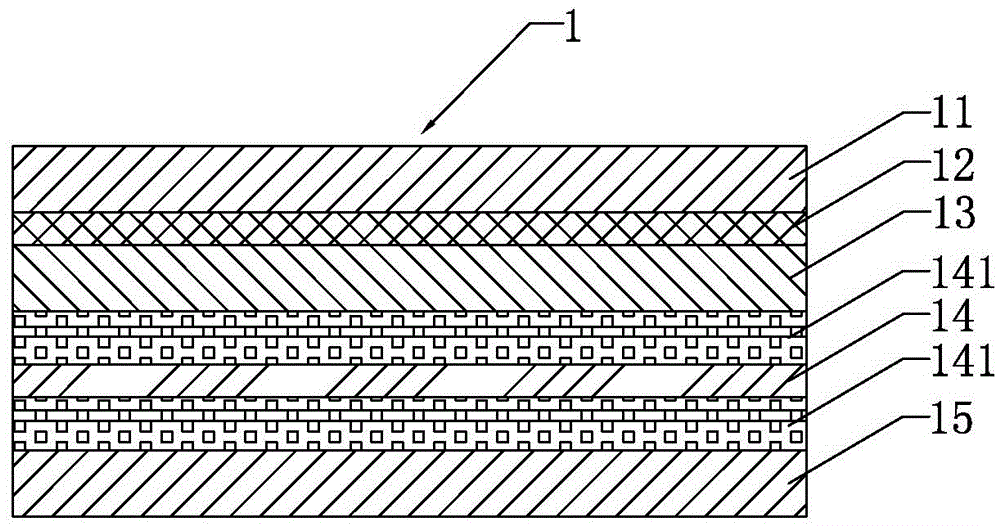

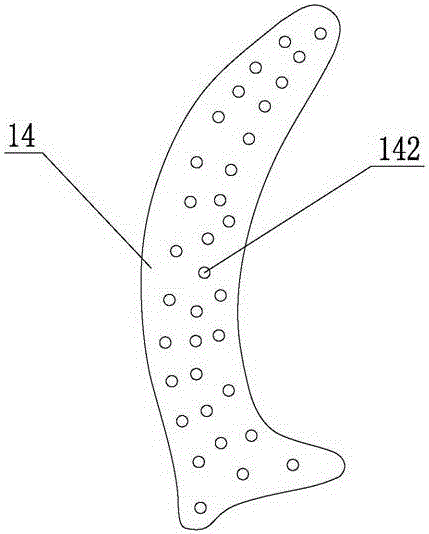

[0052] See Figure 1-2 , a one-piece upright cotton shaping bra, comprising a bra body, the bra body includes two cups 1, and the two cups 1 all include a first upright cotton layer 11, a rubber mesh layer 12, a second The upright cotton layer 13, the film 14 and the third upright cotton layer 15, the inner surface and the outer surface of the rubber mesh layer 12 are respectively thermally bonded with the outer surface of the first upright cotton layer 11 and the inner surface of the second upright cotton layer 13, The inner surface and the outer surface of the film 14 are thermally bonded with the outer surface of the second upright cotton layer 13 and the inner surface of the third upright cotton layer 15 respectively. The through hole 142 runs through its upper and lower surfaces.

[0053] In this embodiment, the mesh shape of the rubber mesh layer 12 is rhombus.

[0054] In the present embodiment, the mesh density of the glue mesh layer 12 is 15-30 / cm 2 .

[0055] In ...

Embodiment 2

[0061] The difference between this embodiment and the above-mentioned embodiment 1 is:

[0062] The glue mesh layer is a silica gel mesh layer, and the silica gel mesh layer is made of the following raw materials in parts by weight:

[0063] Silicone 80 parts

[0064] Vinyl silicone oil 20 parts

[0065] Filler 10 parts

[0066] Plasticizer 10 parts

[0067] Reinforcing agent 5 parts

[0068] sulfur 2 parts

[0069] Lubricant 1 part

[0070] Anti-aging agent 0.5 part.

[0071] The silica gel is a mixture of fluorosilicone raw rubber with a vinyl content of 0.05% and fluorosilicone raw rubber with a vinyl content of 0.12% at a weight ratio of 1:1.4; the filler is titanium dioxide, calcium carbonate and Silicon is a mixture of 0.5:1:2 by weight; the plasticizer is a mixture of diacetin, triethyl citrate and acetyl-n-butyl citrate with a weight ratio of 1.8:0.5:1; The reinforcing agent is a mixture of white carbon black H-5 and white carbon black N20 in a weight ratio of ...

Embodiment 3

[0090] The difference between this embodiment and the above-mentioned embodiment 1 is:

[0091] The glue mesh layer is a silica gel mesh layer, and the silica gel mesh layer is made of the following raw materials in parts by weight:

[0092] Silicone 90 parts

[0093] Vinyl silicone oil 25 parts

[0094] Filler 15 parts

[0095] Plasticizer 12 parts

[0096] Reinforcing agent 8 parts

[0097] 3 parts sulfur

[0098] Lubricant 1.5 parts

[0099] Anti-aging agent 0.8 parts.

[0100] The silica gel is a mixture of fluorosilicone raw rubber with a vinyl content of 0.06% and fluorosilicone raw rubber with a vinyl content of 0.13% at a weight ratio of 1:1.6; the filler is titanium dioxide, calcium carbonate and Silicon is a mixture of 0.8:1:2.5 by weight; the plasticizer is a mixture of diacetin, triethyl citrate and acetyl-n-butyl citrate in a weight ratio of 2:0.8:1; The reinforcing agent is a mixture of white carbon black H-5 and white carbon black N20 in a weight ratio o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com