High-temperature resistant water-based drilling fluid and preparation method thereof

A water-based drilling fluid, high temperature resistant technology, applied in drilling fluid and its preparation, drilling fluid field containing high softening point bitumen composition, can solve the problems of difficult dispersion of particles, difficult crushing of bitumen, etc., to reduce high temperature and high pressure filtration loss The effect of increasing the amount of use, increasing the performance, and improving the density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

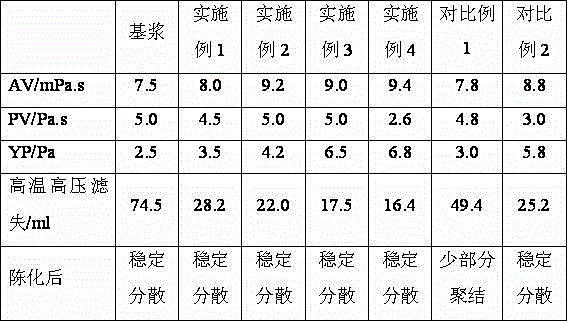

Examples

Embodiment 1

[0030] Add 50g of oxidized asphalt with a softening point of 146.6°C and 50g of deasphalted asphalt with a softening point of 143.3°C into 85g of water, use a high-shear emulsifier to shear for 40 minutes, add 15g of cetyltrimethylammonium chloride, and continue After shearing for 20 minutes, a high softening point asphalt solution (average particle size of asphalt is 96 μm) is obtained.

[0031] Put 24g of high softening point asphalt fluid into 400ml of the prepared drilling fluid base slurry, add carboxymethyl starch accounting for 3% of the drilling fluid mass, and shear at high speed for 15 minutes to obtain a high temperature resistant water-based drilling fluid.

Embodiment 2

[0033] Add 115g of oxidized asphalt with a softening point of 161.6°C to 50g of water, use a high-shear emulsifier to shear for 40 minutes, add 25g of neoprene latex (solid content 30%) and 10g of modified sodium lauryl sulfate, and continue shearing After 25 minutes, high softening point asphalt liquid (average particle size of asphalt 90μm) was obtained.

[0034] Put 20g of high softening point asphalt fluid into 400ml of prepared drilling fluid base slurry, and shear at high speed for 20 minutes to obtain high temperature resistant water base drilling fluid.

Embodiment 3

[0036]Add 90g of oxidized asphalt with a softening point of 153.0°C to 80g of water, use a high-shear emulsifier to shear for 30 minutes, add 16g of styrene-butadiene latex (solid content 40%) and 14g of sodium lignosulfonate and continue to shear for 15 minutes , to obtain high softening point asphalt liquid (average particle size of asphalt 108μm).

[0037] Put 18g of high softening point asphalt fluid into 400ml of the prepared drilling fluid base slurry, add phosphate ester starch accounting for 1.5% of the drilling fluid mass, and shear at high speed for 10 minutes to obtain a high temperature resistant water-based drilling fluid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com