An online pressure metal heat treatment process and its heat treatment device

A metal heat treatment and pressure technology, applied in the field of metal heat treatment, can solve the problems of large temperature fluctuations, heating hysteresis, unevenness, etc., and achieve the effect of ensuring surface effect, uniform temperature field, and large temperature fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

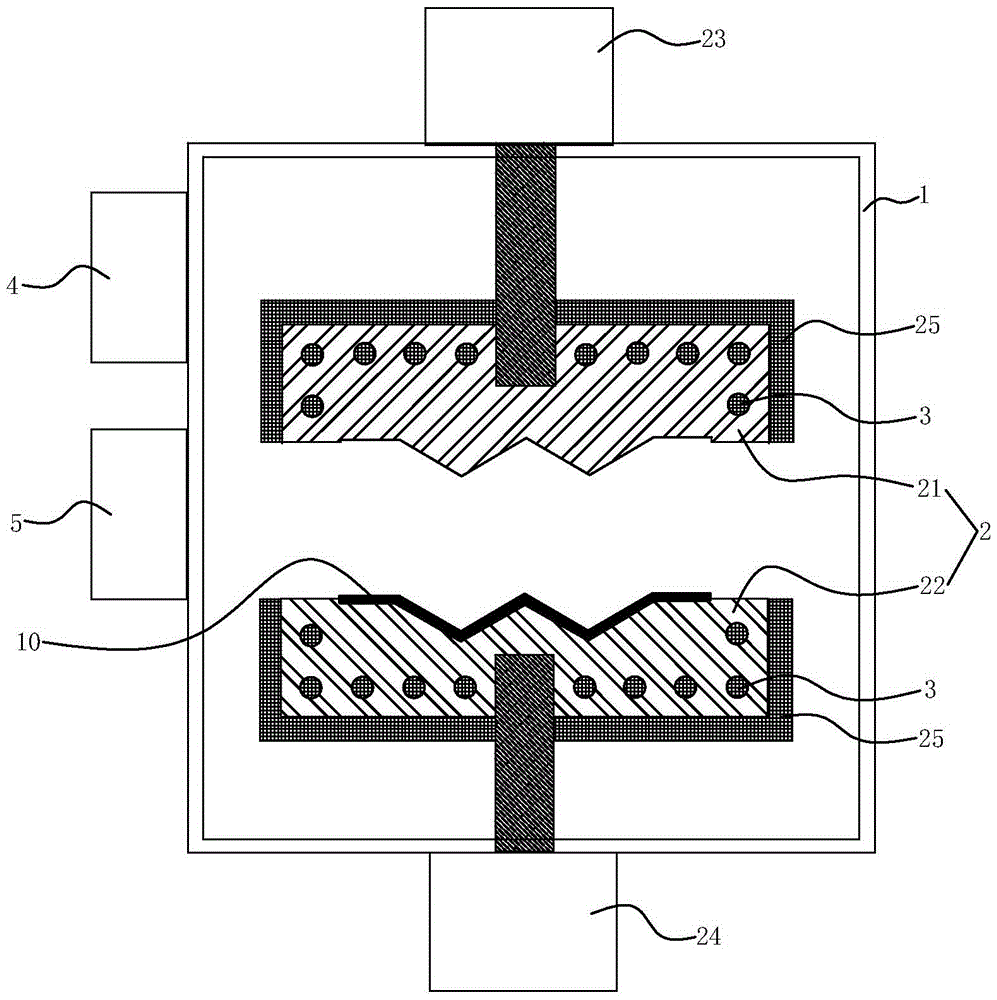

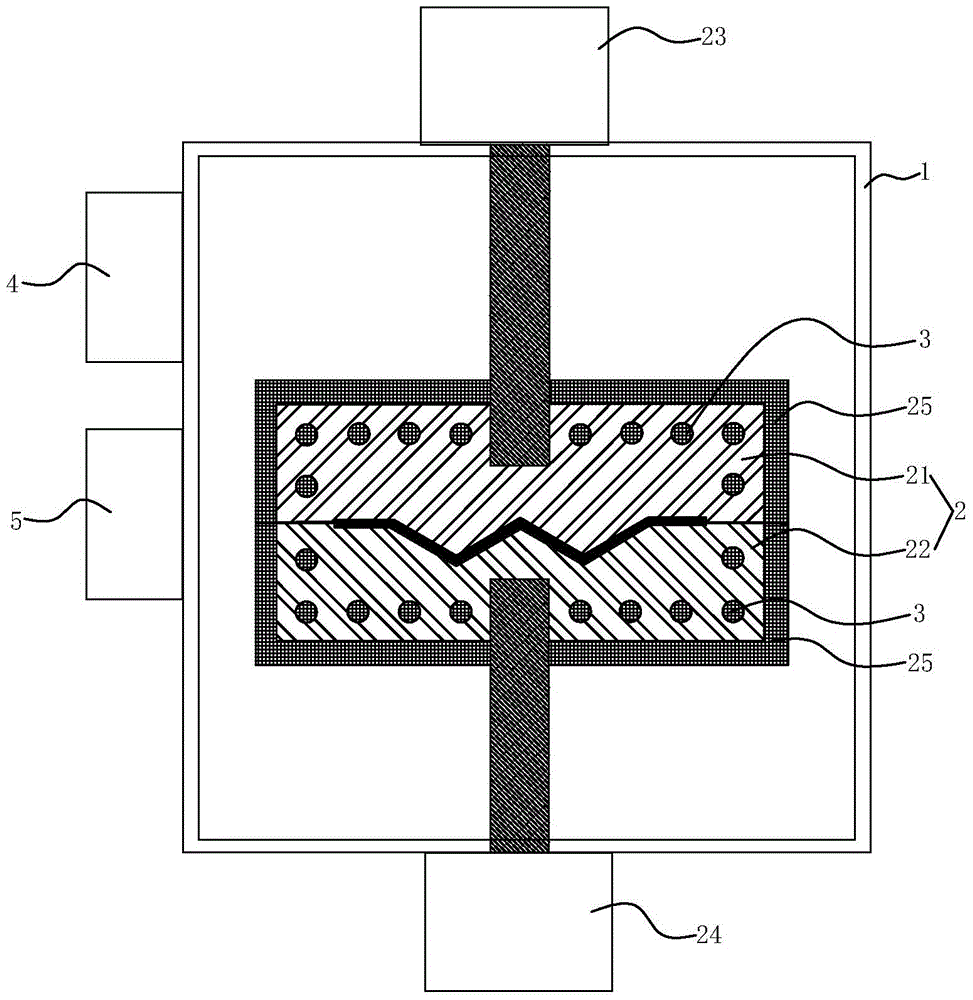

[0028] see Figure 1-2 , is an online pressure metal heat treatment device, which includes: a carrier 1, a pressure mechanism 2 installed in the carrier 1, a heating mechanism 3 installed in the pressure mechanism 2, and a temperature control device 4, Time control device 5, cooling mechanism.

[0029] The pressure mechanism 2 includes: a first pressure seat 21 and a second pressure seat 22 which are installed in the carrier body 1 and can interfere with each other; The first and second drive mechanisms 23 and 24 for the relative movement of the two pressure seats 22, wherein the opposite surfaces of the first pressure seat 21 and the second pressure seat 22 are respectively formed with first and second corresponding and adapted to the workpiece 10. Two-shaped grooves, the first and second grooves are butted to form a cavity, and the outer surfaces of the first pressure seat 21 and the second pressure seat 22 are also provided with a thermal insulation structure 25 .

[0030...

Embodiment 2

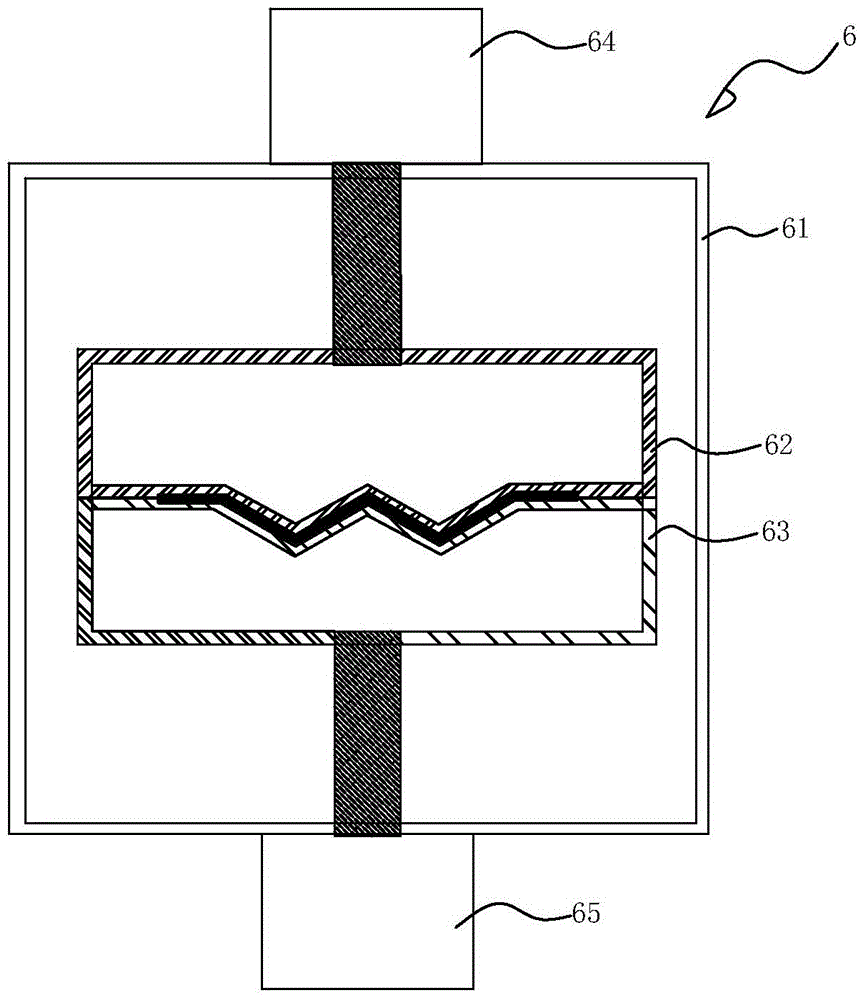

[0046] The difference between the second embodiment and the first embodiment is that the carrier 1 described in the second embodiment is installed on a production line and can move on the production line, so that the pressure mechanism 2 in the carrier 1 Cooperate with the heating mechanism 3 to heat-treat the workpiece while moving on the production line; the cooling mechanism is arranged on the production line. Specifically, the carrier body 1 is installed at one end of the production line, and the cooling mechanism is installed at the other end of the production line. After the pressure mechanism 2 is heated to 600°C and the workpiece is clamped, the pressure mechanism 2 is cooled on the production line. The direction of the mechanism moves, when the first and second pressure seats in the pressure mechanism 2 cooperate with the heating mechanism to carry out heat treatment on the workpiece during the moving process on the production line, wherein the time for the first and s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com