High-density water-based drilling fluid for shale gas horizontal well

A water-based drilling fluid and horizontal well technology, applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems of difficult control of rheological properties, poor temperature resistance, poor lubricity, etc., and achieve easy rheological properties Controlling, excellent inhibition performance, good effect of temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] A method for preparing a high-density water-based drilling fluid for shale gas horizontal wells, comprising the following steps: adding a formula amount of shielding temporary plugging agent, anti-slump inhibitor, solid Lubricant, anti-mud bag cleaner, potassium chloride, sodium hydroxide, fluid loss reducer, flow regulator and barite, accumulatively high-speed stirring for 90 minutes, interrupted every 20 minutes to scrape off the slurry adhered to the cup wall , the high-density water-based drilling fluid for shale gas horizontal wells can be prepared.

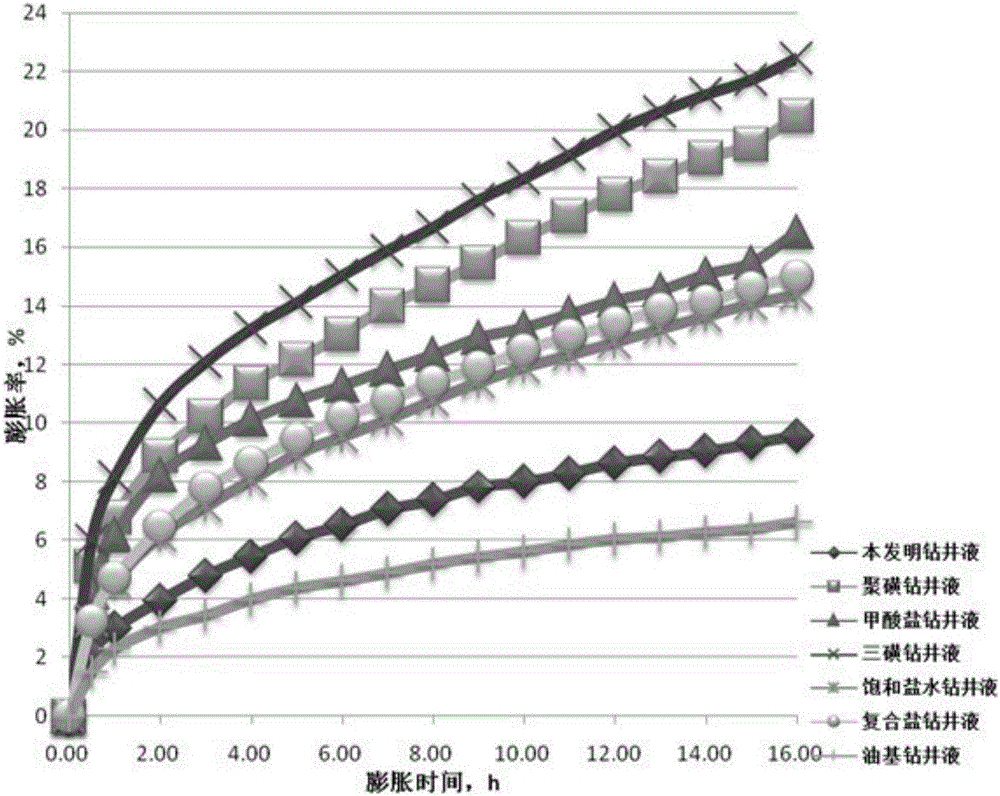

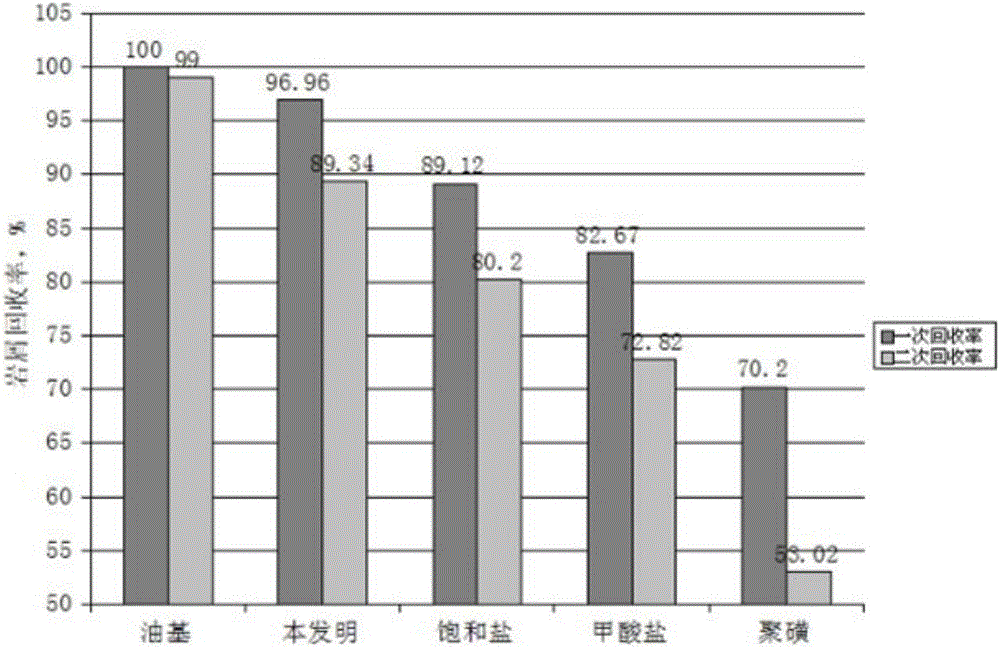

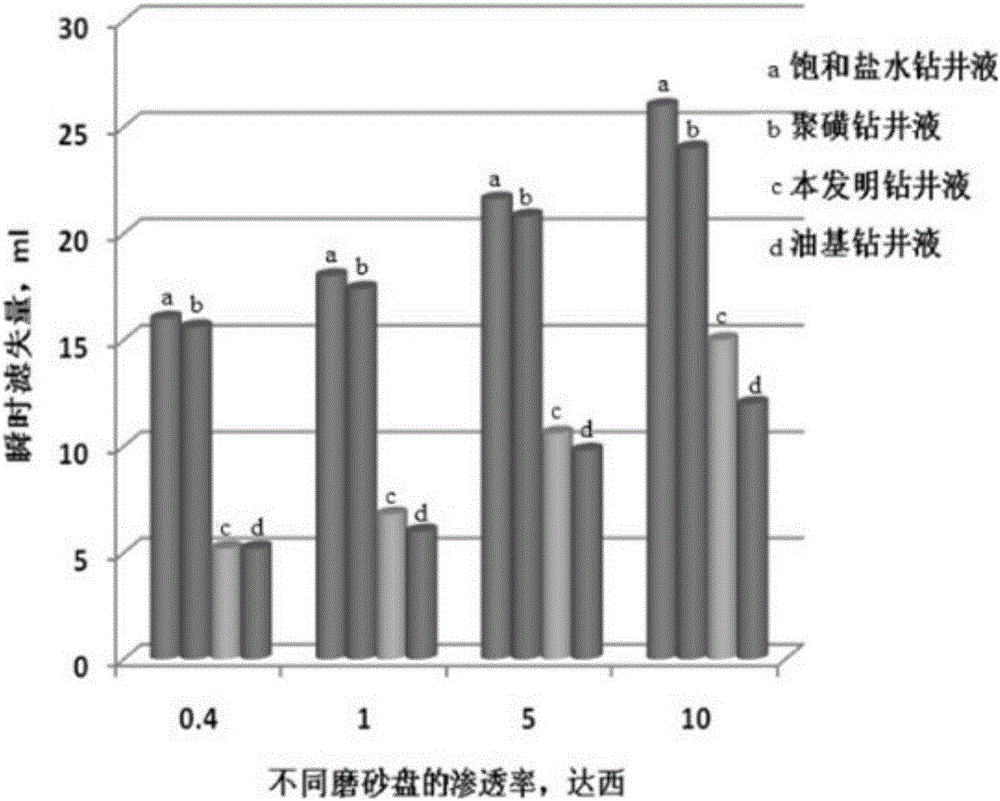

[0032] Compared with oil-based drilling fluid and conventional water-based drilling fluid, the high-density water-based drilling fluid prepared by the present invention has the following outstanding advantages: 1. Excellent plugging performance and inhibition performance can meet the requirements of shale and carbonaceous mudstone on drilling Its anti-slump performance is equivalent to that of oil-based drilling fluid...

Embodiment 1

[0036]Measure 300mL tap water into a 500mL high stirring cup, add 6% shielding temporary blocking agent, 5% anti-slump inhibitor, 5% solid lubricant, 5% anti-mud bag cleaner, 25% Potassium Chloride, 0.5% Sodium Hydroxide, 3% Fluid Loss Control Agent, 0.5% Flow Pattern Regulator and 50% Barite, accumulatively stirred at high speed for 90 minutes, interrupted every 20 minutes to scrape off the adhesion on the cup wall The slurry can be used to prepare the high-density water-based drilling fluid for shale gas horizontal wells according to the present invention.

Embodiment 2

[0038] Measure 300mL tap water into a 500mL high stirring cup, add 6% shielding temporary blocking agent G314, 3% anti-slump inhibitor G319, 5% solid lubricant G338, 3% anti-mud bag while stirring with a high-speed stirrer Cleaner G318, 20% Potassium Chloride, 0.3% Sodium Hydroxide, 2.2% Fluid Loss Control Agent, 0.5% Flow Pattern Regulator XCD and 60% Barite, total high-speed stirring for 90 minutes, interrupt once every 20 minutes to scrape off sticky The slurry attached to the wall of the cup. That is, the water-based drilling fluid of the present invention is obtained.

[0039] Test 1: the test of the inhibiting performance of the prepared water-based drilling fluid according to Example 2

[0040] The density of the water-based drilling fluid prepared according to Example 2 is 2.2g / cm 3 , the inhibition performance of the high-density water-based drilling fluid was compared with other types of drilling fluid after hot rolling at 150°C for 16 hours, the results are as fol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com