Drilling fluid for resisting heavy oil pollution

A drilling fluid and heavy oil technology, applied in the direction of drilling composition, chemical instruments and methods, etc., can solve the problems of funnel viscosity, shear force increase, loss of fluidity, drilling fluid slippage, etc., to reduce high temperature and high pressure filtration Loss, improve the purification ability, improve the effect of temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

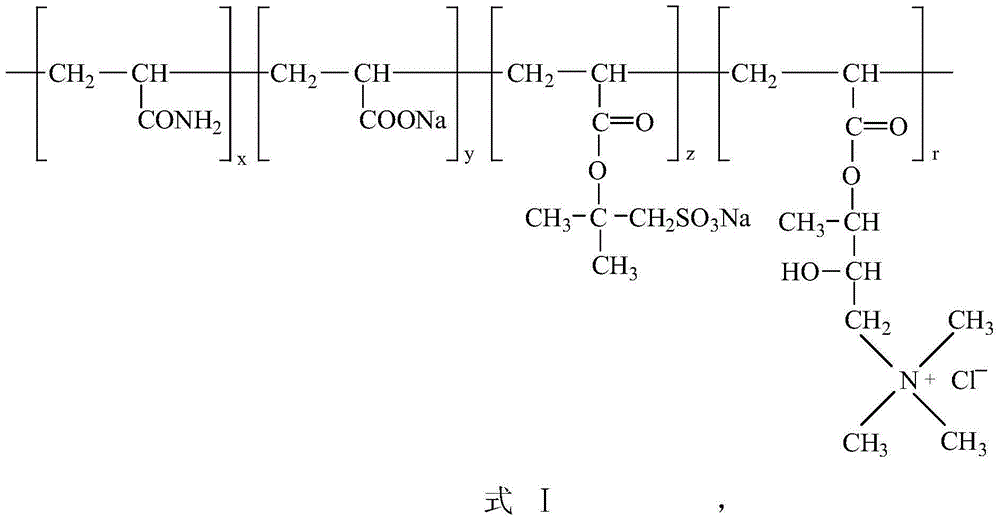

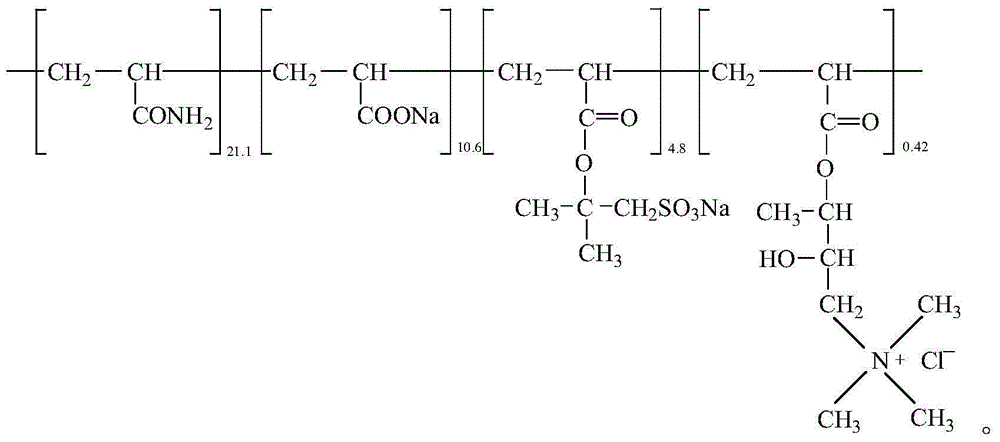

[0020] Preparation of fluid loss additive A1: Mix 26.0 grams of 2-methyl-2-acryloyloxypropylsulfonic acid, 39.0 grams of acrylamide, 20.0 grams of acrylic acid and 2-hydroxy-3-methacryloyloxypropyltrimethyl 2.6 grams of ammonium chloride is formulated into an aqueous solution at room temperature, and the pH value of the aqueous solution is adjusted to 9.0 with sodium hydroxide, then 0.05 grams of ammonium persulfate and 0.05 grams of sodium bisulfite are added to initiate polymerization, and the initial temperature of the polymerization reaction is 20°C , the polymerization time is 5 minutes, and the product is granulated, dried and pulverized to obtain the fluid loss reducer A1, whose structural formula is as follows:

[0021]

preparation example 2

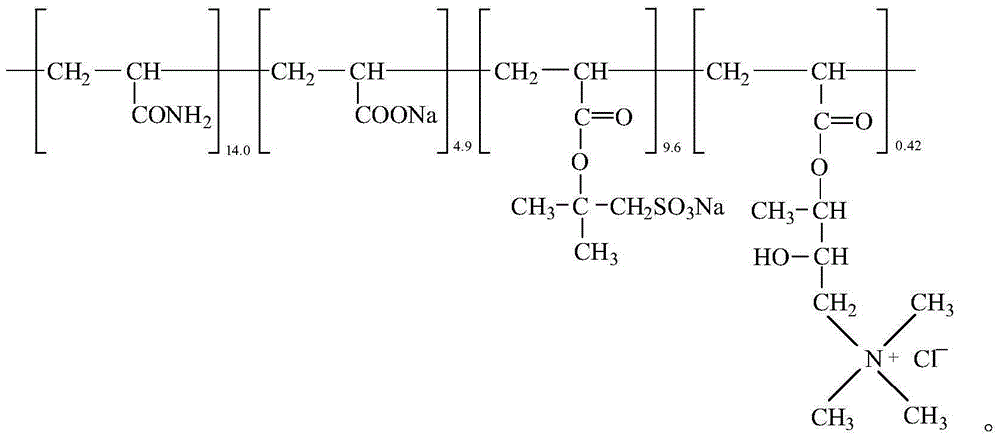

[0023] Preparation of fluid loss additive A2: Mix 56.0 grams of 2-methyl-2-acryloyloxypropylsulfonic acid, 28.0 grams of acrylamide, 10.0 grams of acrylic acid and 2-hydroxy-3-methacryloyloxypropyltrimethyl 2.8 grams of ammonium chloride is formulated into an aqueous solution at room temperature, and the pH value of the aqueous solution is adjusted to 11.0 with sodium hydroxide, then 0.2 grams of potassium persulfate and 0.2 grams of sodium thiosulfate are added to initiate polymerization, and the initial temperature of the polymerization reaction is 50°C , the polymerization time is 20 minutes, the product is granulated, dried and pulverized to obtain the fluid loss reducer A2, and its structural formula is as follows:

[0024]

Embodiment 1

[0026] Take 400 grams of clear water, add 16.0 grams of sodium-based bentonite and 0.8 grams of sodium carbonate to the clear water under high-speed stirring, stir for 20 minutes, and seal and maintain at room temperature for 24 hours to obtain the base slurry; take the above-mentioned base slurry, and add in sequence under high-speed stirring 2.8 grams of carboxymethyl cellulose sodium salt, 1.2 grams of low-viscosity polyanionic cellulose, 12.0 grams of fluid loss additive A, 8.0 grams of sulfonated phenolic resin, 8.0 grams of sulfonated lignite, stirred for 20 minutes; then added 80.0 grams of industrial salt gram, stirred at high speed to fully dissolve, then added 2.0 grams of emulsifier B, 2.0 grams of emulsifier C, and 35.0 grams of barite in turn, and then adjusted the pH value to 11 with sodium hydroxide, put it into an aging tank and aged it at 120 ° C and high temperature for 16 hours, the resulting density is 1.20g / cm 3 Anti-heavy oil pollution drilling fluid.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com