Oil-in-water drilling fluid taking biodiesel as dispersion phase as well as preparation method and application thereof

An oil-in-water drilling fluid and biodiesel technology, which is applied in chemical instruments and methods, drilling compositions, etc., can solve the problem that the drilling fluid pump and other fluid transport mechanical loads are large, and no oil-in-water drilling fluid is found in technical reports, Affecting oil-in-water drilling fluid rheology and other issues, achieving the effects of low cost, good anti-pollution performance and moderate viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

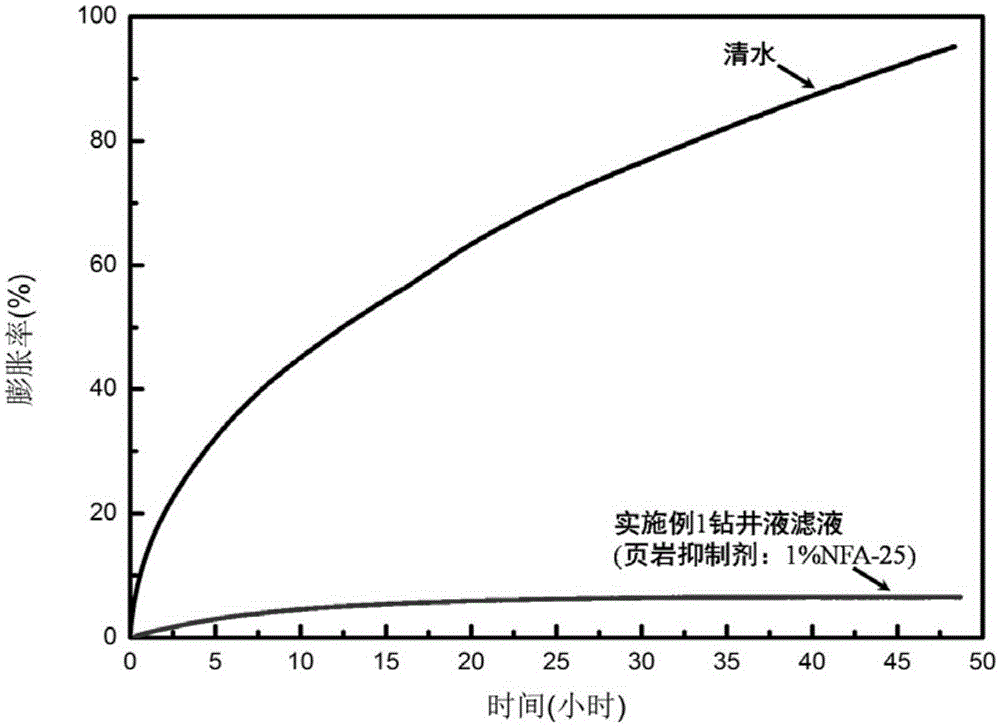

Embodiment 1

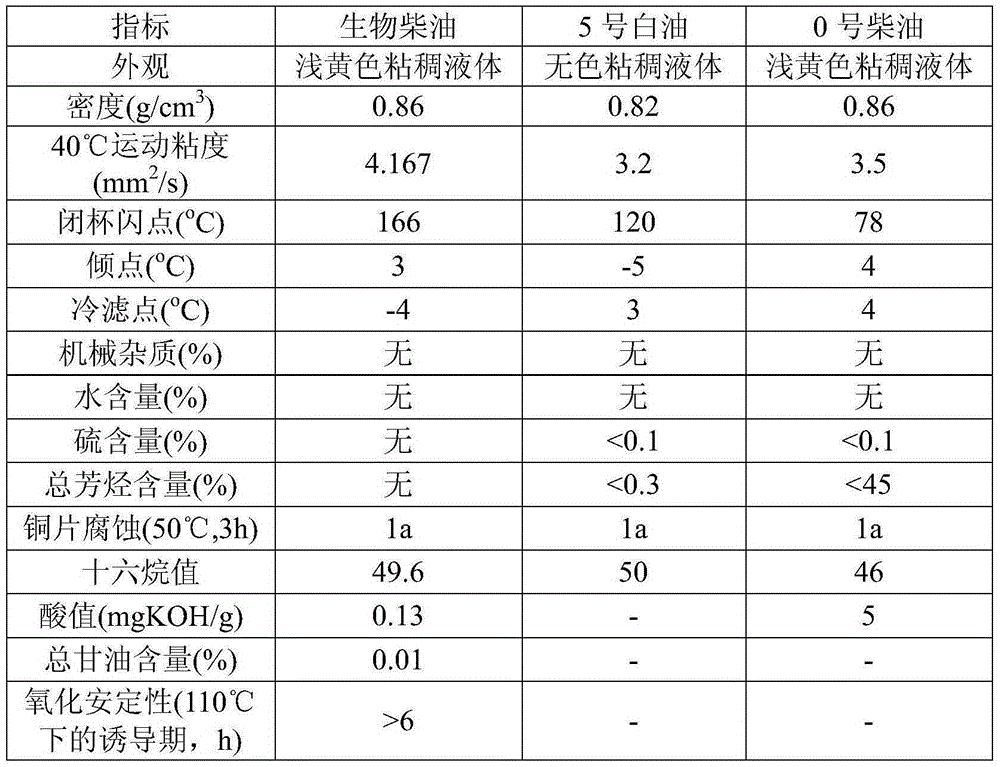

[0079] The formula of the present embodiment oil-in-water drilling fluid:

[0080] 50 parts by volume of fresh water;

[0081] 50 parts by volume of biodiesel;

[0082] And based on the total volume of fresh water and biodiesel as 100% meter: mass volume ratio (g / mL) is 0.15% sodium carbonate, mass volume ratio (g / mL) is 3% bentonite, mass volume ratio (g / mL ) is 0.03% sodium hydroxide, mass volume ratio (g / mL) is 4% main emulsifier Tween-20, mass volume ratio (g / mL) is 0.5% secondary emulsifier Span-85, mass volume ratio (g / mL) is 1% shale inhibitor NFA-25 and mass volume ratio (g / mL) is 0.6% low viscosity sodium carboxymethyl cellulose.

[0083] The preparation method of the oil-in-water drilling fluid of embodiment 1 is as follows:

[0084] Under high-speed stirring conditions, slowly add sodium carbonate, bentonite, and sodium hydroxide to fresh water in sequence, stir at high speed for 30 minutes, seal, and maintain at room temperature for 24 hours to obtain base slurr...

Embodiment 2

[0114] The formula of the present embodiment oil-in-water drilling fluid:

[0115] 70 parts by volume of fresh water;

[0116] 30 parts by volume of biodiesel;

[0117] And based on the total volume of fresh water and biodiesel as 100% meter: mass volume ratio (g / mL) is 0.2% sodium carbonate, mass volume ratio (g / mL) is 4% bentonite, mass volume ratio (g / mL ) is 0.03% sodium hydroxide, mass volume ratio (g / mL) is 3% primary emulsifier MOA-9, mass volume ratio (g / mL) is 0.5% secondary emulsifier Span-80, mass volume ratio (g / mL) is 1.2% shale inhibitor NFA-25, mass volume ratio (g / mL) is 4% fluid loss control agent (2% sulfomethyl lignite and 2% sulfomethyl phenolic resin ).

[0118] Comparing the formulas of Example 2 and Example 1, it can be seen that the main difference between the two is: in Example 2, the water-oil ratio is changed to 70:30; MOA-9 is used as the main emulsifier, and Span-80 is used as the main emulsifier. As the co-emulsifier, use a mixture of sulfomet...

Embodiment 3

[0125] The formula of the present embodiment oil-in-water drilling fluid:

[0126] 70 parts by volume of fresh water;

[0127] 30 parts by volume of biodiesel;

[0128] And based on the total volume of fresh water and biodiesel as 100% meter: mass volume ratio (g / mL) is 0.05% sodium carbonate, mass volume ratio (g / mL) is 1% bentonite, mass volume ratio (g / mL ) is 0.025% sodium hydroxide, the mass volume ratio (g / mL) is the main emulsifier MOA-9 of 2.5%, the mass volume ratio (g / mL) is the secondary emulsifier Span-80 of 0.4%, the mass volume ratio (g / mL) is 1.5% shale inhibitor NFA-25, mass volume ratio (g / mL) is 4% fluid loss control agent (2% sulfomethyl lignite and 2% sulfomethyl phenolic resin ) and a tackifier with a mass volume ratio (g / mL) of 0.1% to 0.3% (a temperature-resistant and salt-resistant polyacrylamide with a molecular weight of 16 million and a degree of hydrolysis of about 20%).

[0129] Comparing the formulas of Example 3 and Example 2, it can be seen t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com