A kind of nano polymer latex, preparation method and application thereof

A technology of polymer latex and nano-polymer, which is applied in the field of nano-polymer polymer latex and preparation, and can solve the problems of composition ratio and manufacturing method that need to be studied.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

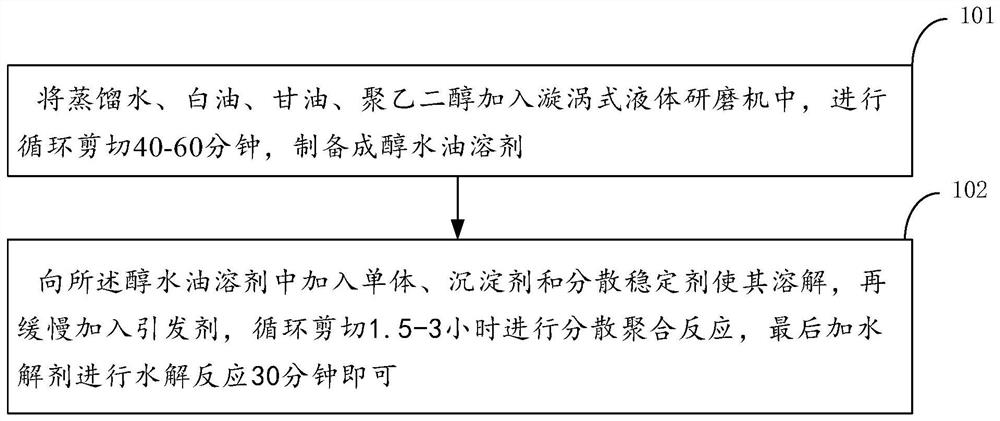

[0038] A method for preparing nanometer polymer latex, comprising the following steps:

[0039]Step 101: Add the mixed solvent of alcohol and water into the reaction kettle, add humic acid while stirring, and add sodium hydroxide to adjust the pH to 11, and stir for 30 minutes to dissolve the humic acid.

[0040] Step 102: Add modified starch, acrylamide and aluminum salt to (1), stir and mix evenly, then add initiator and complexing agent-ethylenediaminetetraacetic acid, and stir at 40-60°C under nitrogen protection The dispersion polymerization was carried out for 2-5 hours.

[0041] Step 103: After the reaction is completed, perform suction filtration and separation, and dry to obtain nanometer polymer latex.

Embodiment 1

[0043] (1) Add 10kg of distilled water, 6kg of white oil, 5kg of glycerin, and 5kg of polyethylene glycol into a vortex type liquid grinder, carry out circular shearing for 40 minutes, and prepare an alcohol-water-oil solvent for use.

[0044] (2) Add 38kg N-vinylpyridine, 26kg epichlorohydrin, 2kg titanium tetrachloride and 5.5kg polyoxyethylene diamine to (1) and dissolve them by shearing for 10 minutes, then slowly add 0.5kg over Oxidize tert-butyl benzoate, cyclically shear for 1.5 hours to carry out dispersion polymerization, and finally add 8kg of ammonia water to carry out hydrolysis for 30 minutes to obtain the product of the present invention.

Embodiment 2

[0046] (1) Add 12kg of distilled water, 12kg of white oil, 4.5kg of glycerin, and 1.5kg of polyethylene glycol into a vortex type liquid grinder, carry out cyclic shearing for 45 minutes, and prepare an alcohol-water-oil solvent,

[0047] (2) Add 34kg of N-vinylpyridine, 20kg of epichlorohydrin, 3kg of yttrium trichloride and 6kg of polyoxyethylenediamine to (1) for 10 minutes to dissolve, then slowly add 1kg of benzene peroxide tert-butyl formate, cyclic shearing for 2 hours to carry out dispersion polymerization reaction, and finally add 6 kg of 20% sodium hydroxide aqueous solution to carry out hydrolysis reaction for 30 minutes to obtain the product of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com