High temperature resistant non-fluorescence anti-sloughing nano-filtrate reducer and preparation method thereof

A fluid loss additive, non-fluorescence technology, applied in the field of nanomaterials, can solve the problems of increasing drilling fluid viscosity, low high temperature resistance, increased maintenance and processing difficulty, etc., and achieves the effect of inhibiting shale expansion and improving shale expansion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

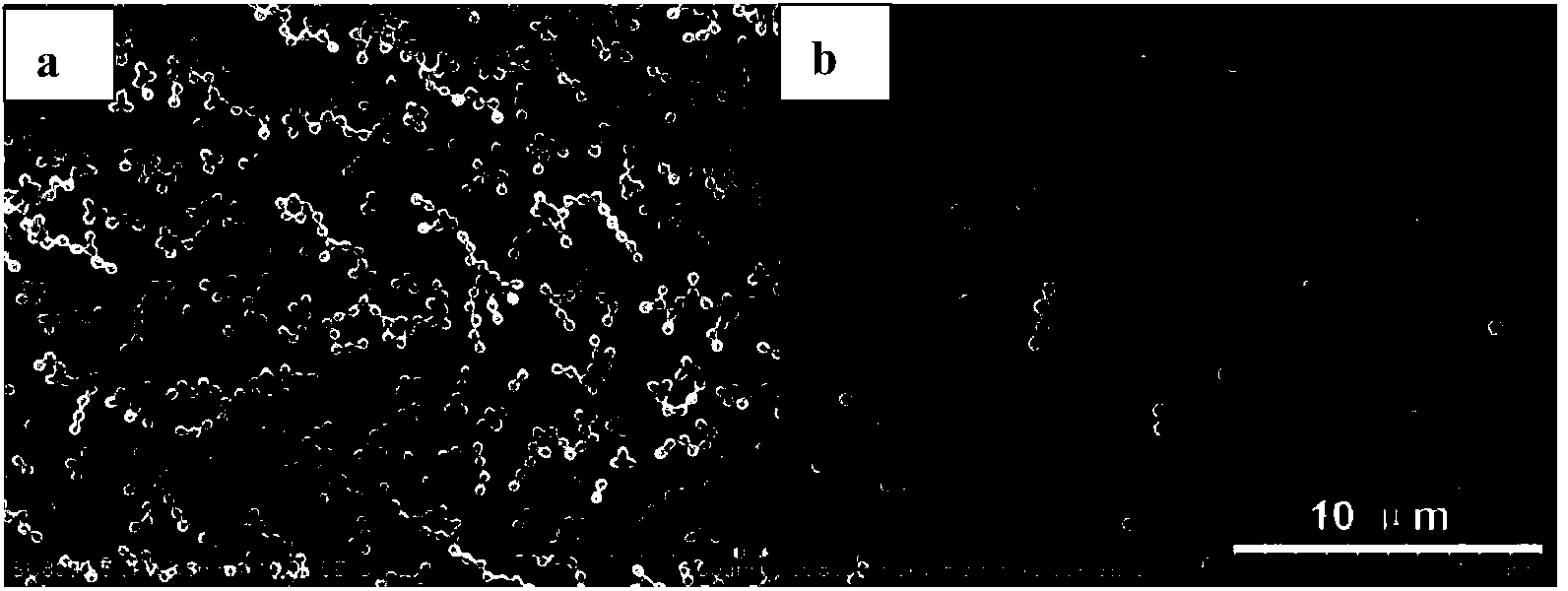

Image

Examples

Embodiment 1

[0029] Add 0.5 g of K to 100 mL of distilled water 2 S 2 o 8 After dissolving it, add 5mL of methyl methacrylate and 3g of acrylamide in a nitrogen environment at a reaction temperature of 60-70°C, stir at high speed, react for 1.5h, centrifuge and dry to obtain nano-scale anti-slump fluid loss additives 1.

Embodiment 2

[0031] After adding 0.3g of azobisisobutyronitrile into 100mL of distilled water to dissolve it, in an argon atmosphere at a reaction temperature of 80-85°C, add 5mL of methyl acrylate and 3g of 2-acrylamido-2-methylpropanesulfonate Acid, stirred at high speed, reacted for 4 hours, centrifuged and dried to obtain nanometer anti-slump fluid loss additive 2. Example 3

Embodiment 3

[0032] Add 0.5g (NH 4 ) 2 S 2 o 8 After dissolving it, add 3mL methyl methacrylate and 3mL methyl acrylate in a helium environment at a reaction temperature of 60-70°C, react for 40min under stirring conditions, then add 2mL methyl methacrylate and 3g Acrylamide was reacted for 1.0 h under stirring condition, centrifuged and dried to obtain nano-scale anti-slump fluid loss reducer 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com