Primary emulsifier and preparation method therefor, emulsifier composition and application thereof, and oil-based drilling fluid

A technology of main emulsifier and emulsifier, which is applied in the field of oil-based drilling fluid, can solve the problems of adverse environmental impact and high preparation cost, and achieve the effect of cheap source, good temperature resistance stability and wide source

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

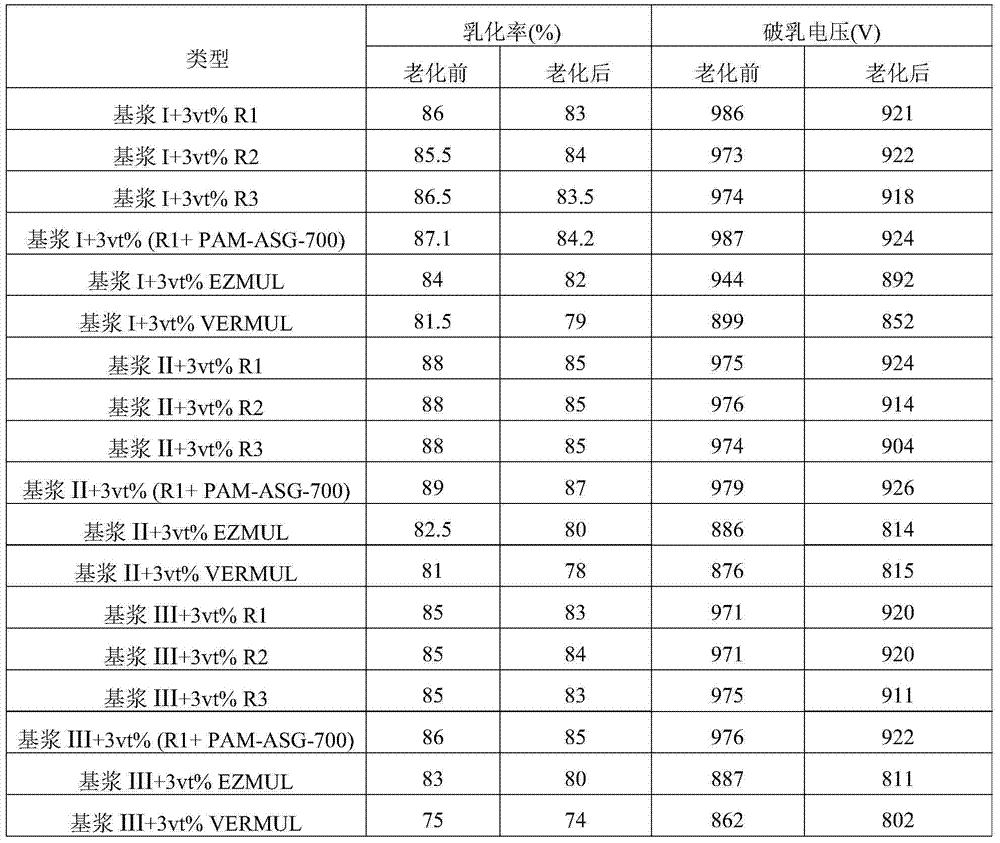

Examples

specific Embodiment approach

[0027] According to a specific embodiment of the present invention, the amide compound is prepared in the following manner: at room temperature, mix the polyamine compound and the first unsaturated fatty acid, stir at a low speed of 80-100r / min for 20-30min, Then adjust the pH value of the obtained mixture to 7-9, then use an oil bath to heat the mixture to 220-230°C, and at the same time use a water separator to divide water, and maintain the temperature at 220-230°C for 3-5 hours, Then cool to room temperature to obtain "incomplete amide"; then at room temperature, mix "incomplete amide" with acid anhydride and / or polycarboxylic acid, and then use a water bath to heat the resulting mixture to 75-90°C, at 200- Stir at 500r / min for 6-10 hours.

[0028] The fatty acid compounds can be obtained commercially, or can be prepared according to various methods known in the art. Preferably, the fatty acid compound is prepared according to the following method: at 150-180°C, the secon...

Embodiment 1

[0052] This embodiment is used to illustrate the preparation method of the primary emulsifier provided by the present invention.

[0053] (1) reactant is diethylenetriamine in molar ratio under normal temperature: oleic acid=1:1 (being the consumption of the diethylenetriamine calculated by primary amino group and the consumption of the oleic acid calculated by carboxylic acid group) The molar ratio is 2:1) mixed, and stirred at 250r / min for 20min, then the pH value of the resulting mixture was adjusted to 7, and then the mixture was heated to 225°C using an oil bath, and water was divided by a water divider at the same time, And maintain the temperature at 225°C for 5 hours, then cool to room temperature to obtain the intermediate product "incomplete amide".

[0054] At normal temperature, "incomplete amide" is mixed with oxalic acid (the molar ratio of the amount of diethylenetriamine in terms of primary amino groups to the amount of oxalic acid in terms of carboxylic acid g...

Embodiment 2

[0058] This embodiment is used to illustrate the preparation method of the primary emulsifier provided by the present invention.

[0059] (1) Under normal temperature, the reactant is tetraethylenepentamine in molar ratio: linoleic acid=1:1 (that is, the consumption of tetraethylenepentamine calculated by primary amino groups and the amount of linoleic acid calculated by carboxylic acid groups The molar ratio of the amount used is 2:1) mixed, and stirred at 250r / min for 40min, then the pH value of the obtained mixture was adjusted to 9, and then the mixture was heated to 230°C with an oil bath, and at the same time, it was divided by water separation water, and the temperature was maintained at 230 ° C for 3 hours, cooled to room temperature, and the intermediate product "incomplete amide" was obtained.

[0060] At normal temperature, "incomplete amide" is mixed with malonic acid (the molar ratio of the amount of tetraethylenepentamine in terms of primary amino groups and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com