Preparation of phosphate radical-responsive carbon quantum dots and application of phosphate radical-responsive carbon quantum dots in fingerprint fluorescence recognition

A technology of carbon quantum dots and fluorescence recognition, which is applied in the direction of fluorescence/phosphorescence, nano-carbon, luminescent materials, etc., can solve the problems of unfavorable large-scale production and application, and achieve the effect of low cost, simple preparation process and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] 1. Add 50mL of ultrapure water to a 100mL beaker, then add 0.15mmol of 1,2,4-glucinol, and stir for 3 minutes with magnetic force to obtain a 1,2,4-glucinol solution.

[0042] 2. Put the 1,2,4-glucinol solution obtained in step 1 into a polytetrafluoroethylene-lined autoclave, react at 170°C for 6 hours, centrifuge at 8000r / min after the reaction is completed, and take The supernatant was used for later use.

[0043] 3. The supernatant obtained in step 2 was subjected to rotary evaporation and vacuum freeze-drying to obtain a black solid powder.

[0044] 4. Dissolve 0.3 mg of the solid powder obtained in step 3 in 1 mL of ultrapure water to obtain a mother liquor for use.

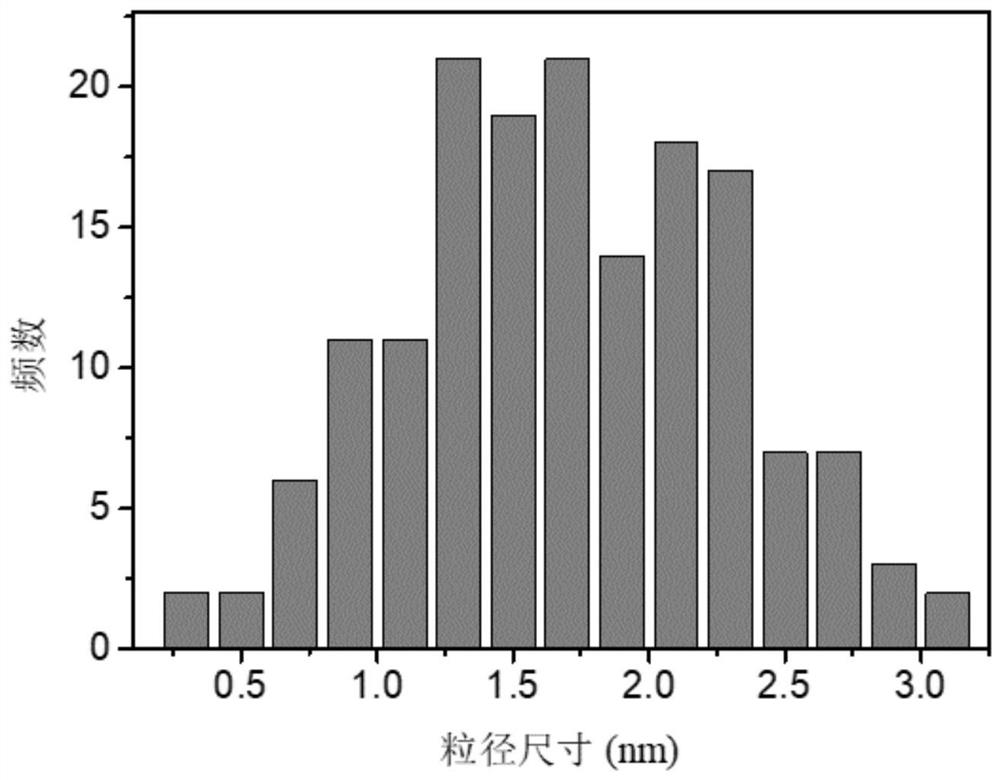

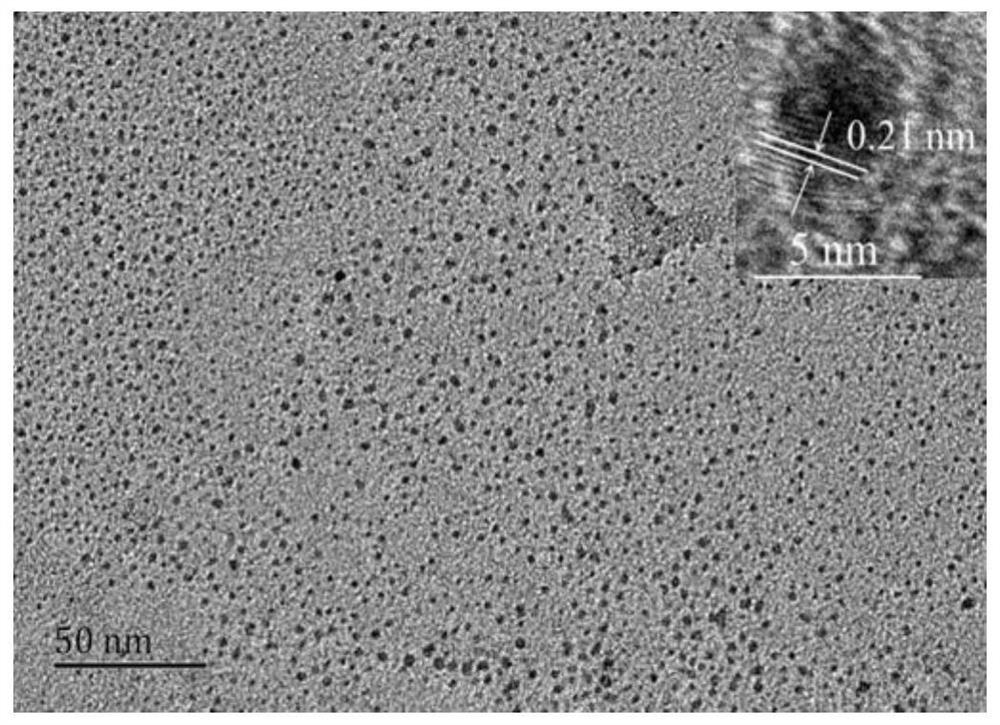

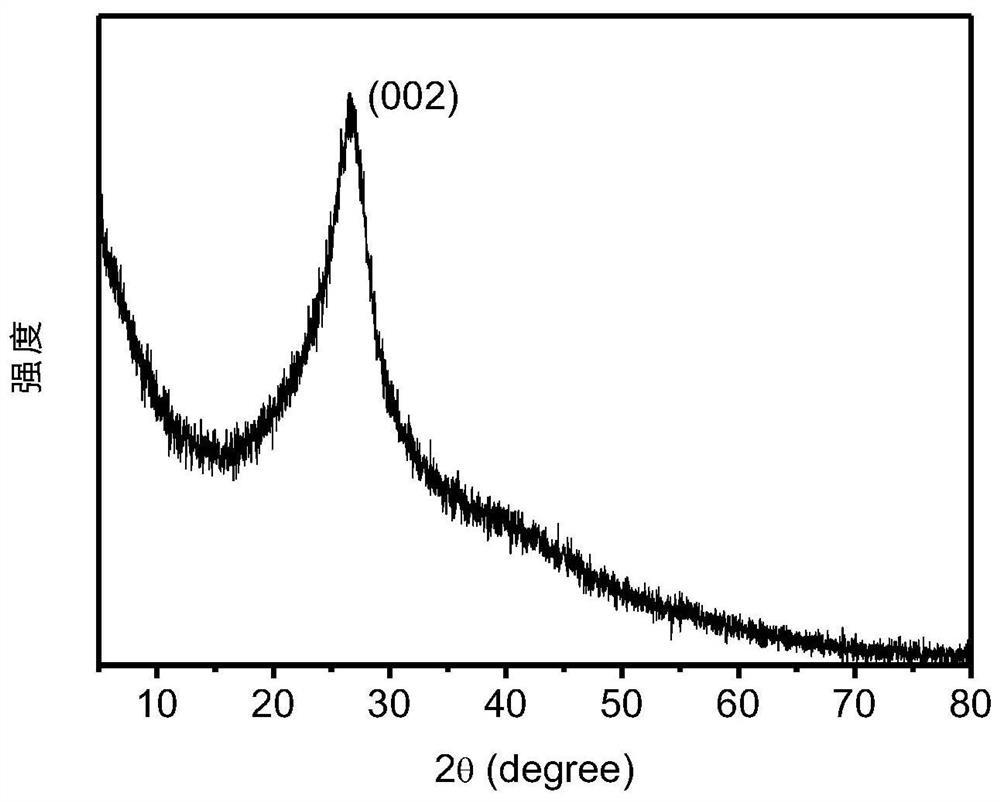

[0045] 5. Observing the mother liquor under a field emission transmission electron microscope, the size of the carbon quantum dots is 0.31 to 3.19 nm, and the average particle diameter is about 1.7 ± 0.38 nm (see attached figure 1 ). The obtained solid powder is tested by high-resolution transmiss...

Embodiment 2

[0049] 1. Add 50mL of ultrapure water to a 100mL beaker, then add 0.074mmol of 1,2,4-glucinol, and stir for 3 minutes with magnetic force to obtain a 1,2,4-glucinol solution.

[0050] 2. Put the 1,2,4-glucinol solution obtained in step 1 into a polytetrafluoroethylene-lined autoclave, react at 150°C for 4 hours, centrifuge at 8000r / min after the reaction is completed, and take The supernatant was used for later use.

[0051] 3. The supernatant obtained in step 2 was subjected to rotary evaporation and vacuum freeze-drying to obtain a black solid powder.

[0052] 4. Dissolve 0.3 mg of the solid powder obtained in step 3 in 1 mL of ultrapure water to obtain a mother liquor for use.

Embodiment 3

[0054] 1. Add 50mL of ultrapure water to a 100mL beaker, then add 0.3mmol of 1,2,4-glucinol, and stir for 3 minutes with magnetic force to obtain a 1,2,4-glucinol solution.

[0055] 2. Put the 1,2,4-glucinol solution obtained in step 1 into a polytetrafluoroethylene-lined autoclave, react at 180°C for 8 hours, centrifuge at 12000r / min after the reaction is completed, and take The supernatant was used for later use.

[0056] 3. The supernatant obtained in step 2 was subjected to rotary evaporation and vacuum freeze-drying to obtain a black solid powder.

[0057] 4. Dissolve 0.3 mg of the solid powder obtained in step 3 in 1 mL of ultrapure water to obtain a mother liquor for use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| lattice spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com