Temperature resistance and salt tolerance extreme pressure lubricant for high density drilling fluid and preparation method thereof

A technology of extreme pressure lubricants and drilling fluids, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems that do not involve temperature resistance and adhesion coefficient reduction, and achieve excellent temperature and salt resistance, Reduced friction coefficient and strong hydrolytic stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

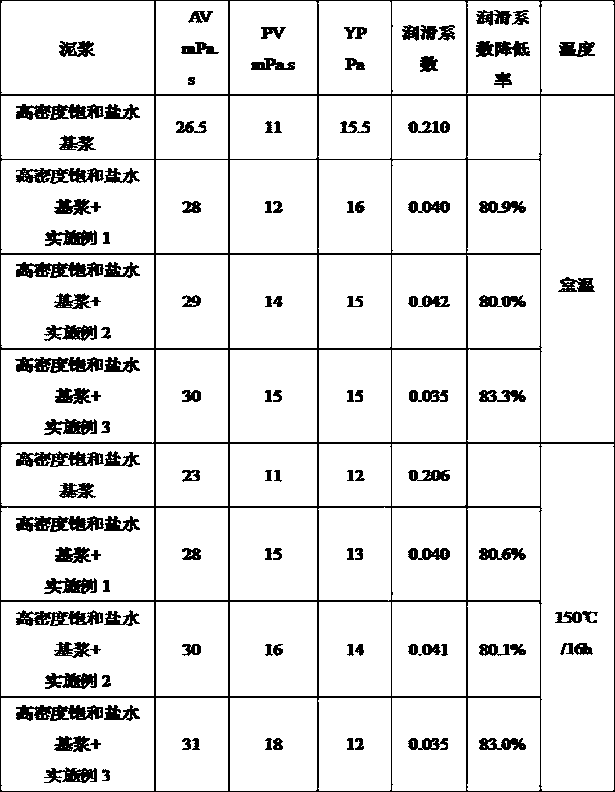

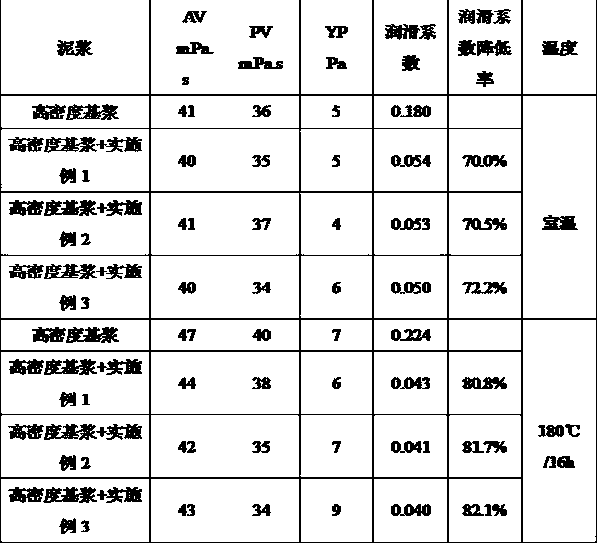

Embodiment 1

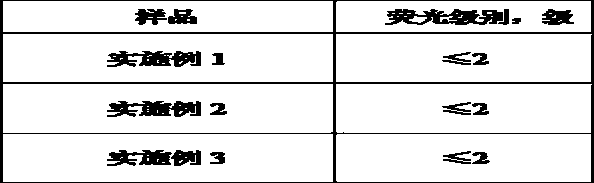

[0040] While stirring, add 80 parts of sulfonated methyl oleate into the reaction kettle, heat up to 50 °C, add 6 parts of oleic acid and stir for 30 min, then heat up to 95 °C, then add 6 parts of sulfurized fatty acid methyl ester and 2 One part of methylene bis-dibutyl dithiocarbamate was stirred for 20 min, and finally 3 parts of emulsifier were added (the emulsifier was a mixture of nonionic surfactants OP-10 and SP-80, and the mass mixing ratio was OP- 10: SP-80=2:3) and 3 parts of silicone defoamer cooled to room temperature while stirring, the resulting black red liquid is non-fluorescence anti-temperature and anti-salt extreme pressure lubricant for high-density drilling fluid.

Embodiment 2

[0042] While stirring, add 82 parts of sulfonated methyl oleate into the reaction kettle, heat up to 60 °C, add 5 parts of oleic acid and stir for 30 min, then heat up to 100 °C, then add 5 parts of sulfurized fatty acid methyl ester and 3 One part of methylene bis-dibutyl dithiocarbamate was stirred for 20 min, and finally 3 parts of emulsifier were added (the emulsifier was a mixture of nonionic surfactants OP-10 and SP-80, and the mass mixing ratio was OP- 10: SP-80=2:3) and 2 parts of silicone defoamer cooled to room temperature while stirring, the resulting black-red liquid is non-fluorescence anti-temperature and anti-salt extreme pressure lubricant for high-density drilling fluid.

Embodiment 3

[0044] While stirring, add 82 parts of sulfonated methyl oleate into the reaction kettle, heat up to 95 °C, add 5 parts of oleic acid and stir for 30 min, then heat up to 100 °C, add 5 parts of sulfurized fatty acid methyl ester and 3 parts Methylene bis-dibutyl dithiocarbamate was stirred for 20 min, and 3 parts of emulsifier were added (the emulsifier was a mixture of nonionic surfactants OP-10 and SP-80, and the mass mixing ratio was OP-10: SP-80=2:3) and 2 parts of silicone defoamer cooled to room temperature while stirring, the resulting black red liquid is non-fluorescent anti-temperature and anti-salt extreme pressure lubricant for high-density drilling fluid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com