Bone defect repairing material, preparation method and applications thereof

A defect repair and bioceramic material technology, applied in the field of bone defect repair materials and their preparation, to achieve the effect of maintaining integrity and maintaining activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

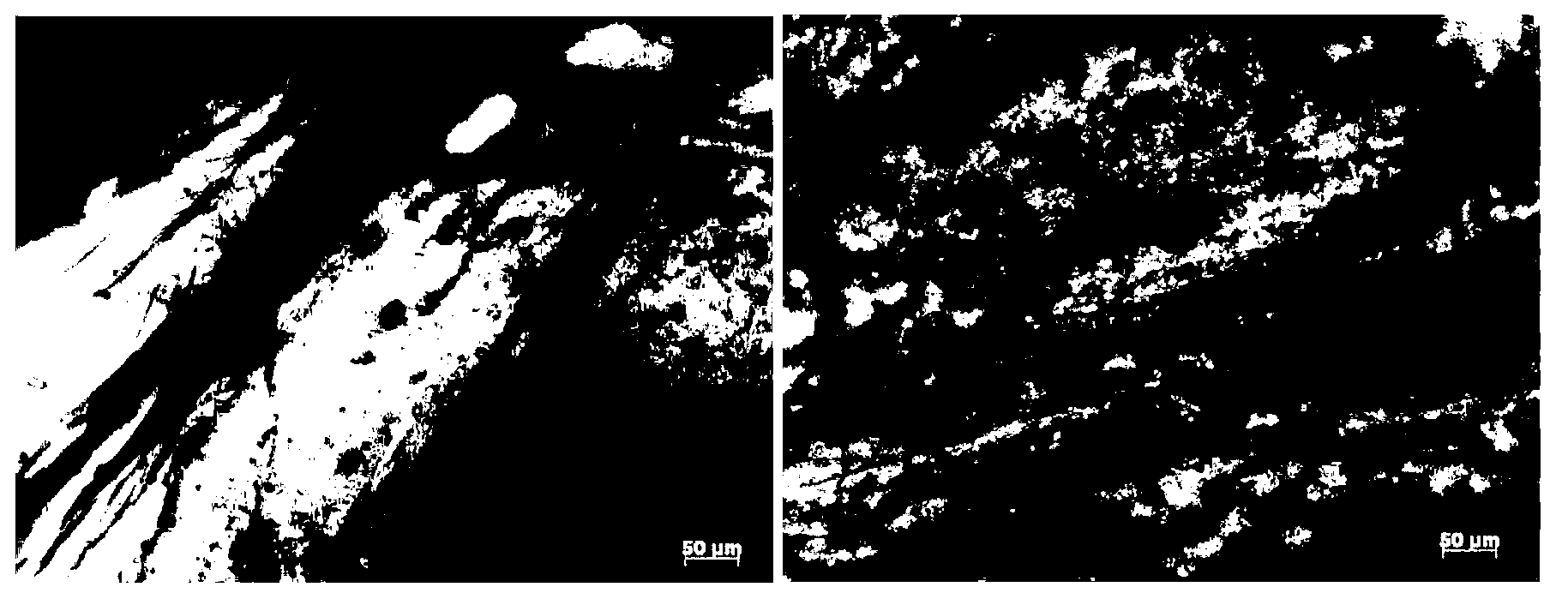

Image

Examples

preparation example Construction

[0034] In addition, this embodiment also provides a method for preparing a bone defect repair material, including the following steps:

[0035] Step 1: Inoculate the cellulose-producing bacteria into the medium and cultivate until a bacterial cellulose film with a thickness of 1-5 mm is obtained, then break the bacterial cells, remove the broken bacterial cells, and collect the bacterial cellulose film.

[0036] For example, you can choose a concentration of 0.80to2.30×10 5 CFU / mL (CFU: Colony Forming Units, number of colonies) Gluconacetobacter strain solution, the strain solution was inoculated into the medium at a ratio of 1:50-100, and cultured statically at 28-32°C . Among them, the composition of the medium is as follows: 0.1-0.4g / mL glucose, 0.03-0.06g / mL peptone, 0.02-0.03g / mL anhydrous disodium hydrogen phosphate, 0.01-0.02g / mL citric acid, 0.005-0.015g / mL magnesium sulfate, 0.005-0.01g / mL ammonium sulfate and 0.005-0.015% volume percentage of corn syrup extract, an...

Embodiment 1

[0046] Step 1: Select a concentration of 0.80to2.30×10 5 CFU / mL Gluconacetobacter strain solution, inoculate the strain solution into the culture medium at a ratio of 1:100, and culture it statically at 30°C. Among them, the composition of the medium is as follows: 0.1-0.4g / mL glucose, 0.03-0.06g / mL peptone, 0.02-0.03g / mL anhydrous disodium hydrogen phosphate, 0.01-0.02g / mL citric acid, 0.005-0.015g / mL magnesium sulfate, 0.005-0.01g / mL ammonium sulfate and 0.005-0.015% volume percentage of corn syrup extract, and the solvent of the culture medium is water. When the thickness of the extracellular cellulose membrane reaches 1-5 mm, use a sodium hydroxide solution with a concentration of 0.1 mol / L to vibrate and crush the bacterial cells in a water bath at 80°C, repeat several times until the bacterial cells are completely crushed, and then use Wash the broken cells and sodium hydroxide with deionized water until the pH of the surface of the bacterial cellulose membrane is close...

Embodiment 2

[0059] Calcium triphosphate was used instead of hydroxyapatite.

[0060] Configured as 3mg / mL calcium triphosphate simulated human body fluid suspension.

[0061] Other steps are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com