A biocidal plastic

A plastic and biological technology, applied in the field of plastics, can solve the problems of difficulty in finding, volatile and inactivation of biologically active molecules, etc., and achieve the effects of simple preparation method, harmless environmental pollution, and good bactericidal activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Preparation of polystyrene and β-galactosidase composite plastics: 10 grams of polystyrene nanospheres with a particle size of 150 nm were prepared by emulsion polymerization, washed with absolute ethanol and distilled water for 5 times, and vacuum-dried for later use. Dissolve 10 mg of β-galactosidase in 10 ml of sterile distilled water, stir well, and dissolve to a homogeneous system. Add 10 grams of polystyrene pellets into the system, stir quickly to form a uniform suspension, drain the suspension, put it into a mold and spread it flat, put it into a press through the mold, and heat it at 40°C Apply a pressure of 250 MPa under the same conditions, and keep the pressure for 20 minutes, release the pressure, and demould, and the composite plastic of polystyrene and β-galactosidase can be obtained.

Embodiment 2

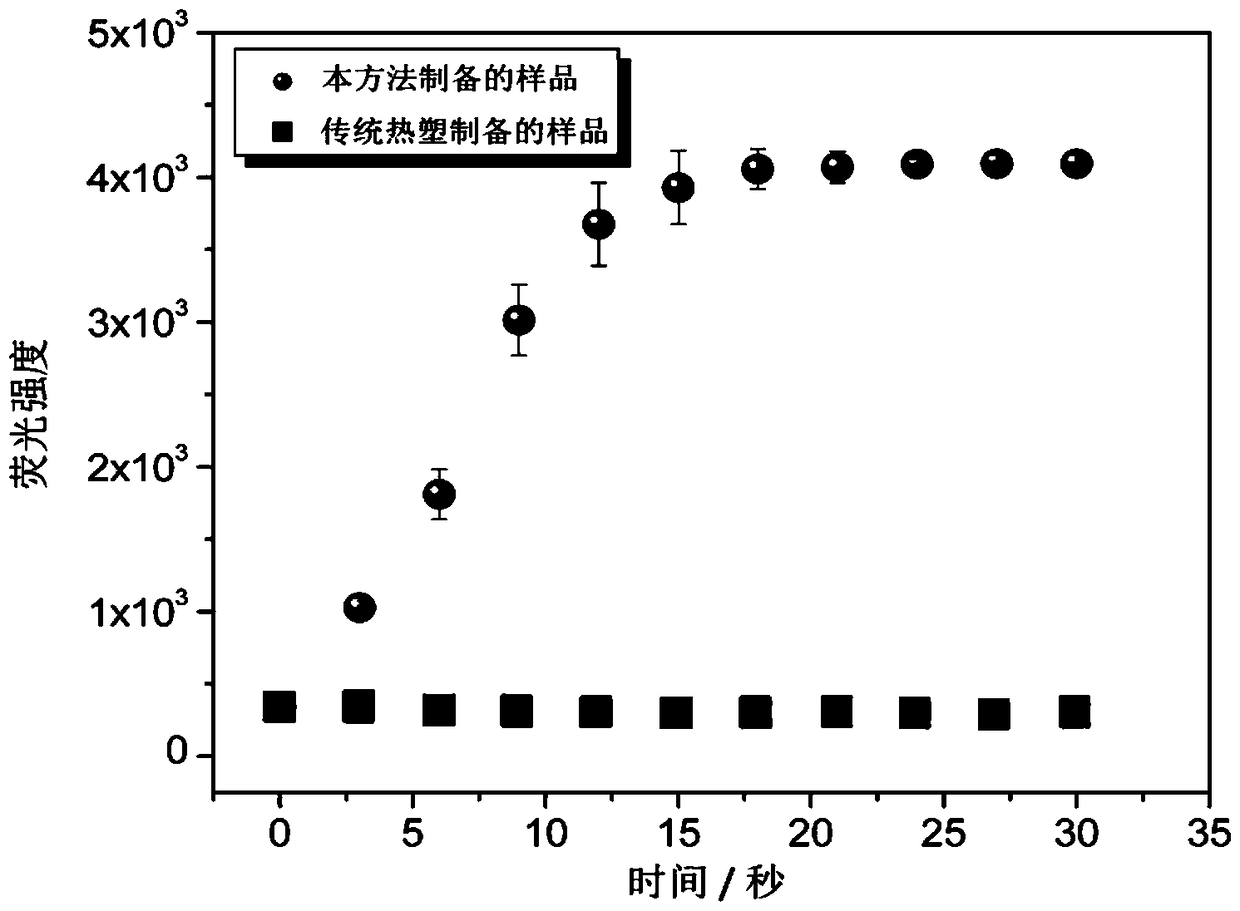

[0018] Design comparative experiments, respectively adopt the traditional thermoplastic processing method and the preparation method at room temperature of the present invention to prepare polystyrene and β-galactosidase composite materials, and use β-galactosidase to catalyze the hydrolysis of β-D Galactopyranoside (RBG) to generate red fluorescent product properties, in verifying whether the activity of the enzyme is maintained, the test results are as follows figure 1 , where the ordinate is the fluorescence intensity of the enzyme-catalyzed reaction product, and the abscissa is the reaction time.

[0019] Depend on figure 1 It can be seen that when the composite material prepared by the traditional thermoplastic processing method catalyzes the hydrolysis of β-D galactopyranoside (RBG), due to the disappearance of the enzyme activity, the reaction cannot proceed, so its fluorescence intensity has been kept at a low level. The numerical value of β-galactosidase remains unch...

Embodiment 3

[0021] Preparation of polyvinyl chloride and bovine serum albumin (BSA) composite plastics: 5 grams of polyvinyl chloride nanospheres with a particle size of about 40 nm were prepared by nanoparticle sedimentation method, washed with absolute ethanol and distilled water for 5 times respectively, and vacuum Dry and set aside. Dissolve 1 gram of bovine serum albumin in 10 ml of sterile distilled water, fully stir and dissolve to a uniform system, add 5 grams of polyvinyl chloride nanospheres to the system, stir rapidly to form a uniform suspension, and mix the After the suspension is drained, put it into a mold and pave it flat, put it into a press through the mold, apply a pressure of 100MPa at 0°C, and keep the pressure for 1min, then release the pressure and demould to obtain polyvinyl chloride and Composite plastic of bovine serum albumin.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com