Preparation method and application of concentrated active packaging patch

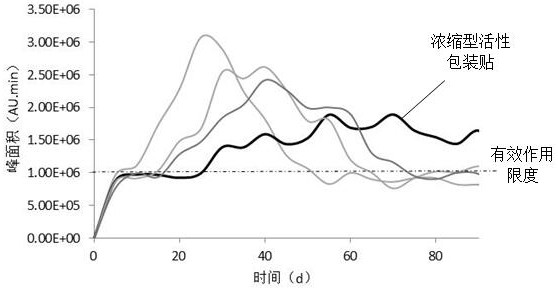

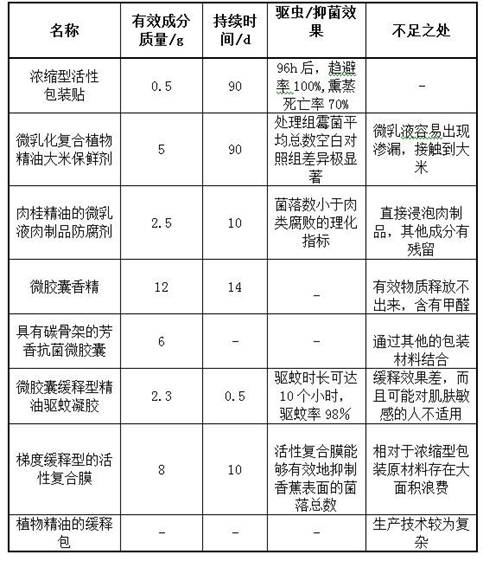

A concentrated and active technology, applied in biocide-containing paints, film/sheet adhesives, antifouling/underwater coatings, etc., can solve problems such as increased costs and waste, and achieve improved utilization and reduced The effect of dosage and prolonging the action time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) Microemulsion preparation: plant essential oil and ultrapure water are mixed according to the ratio of 4:6 (v / v), and at 50°C, gradually add Tween 80 and absolute ethanol according to the ratio of 3:1 (v / v) v) Surfactants mixed in the same ratio and stirred until clear and transparent, it is an essential oil microemulsion.

[0033] (2) Preparation of microcapsules: Spray a uniform mixture of cornstarch and β-cyclodextrin at a ratio of 60:5 (w / w) with 75% absolute ethanol, and obtain 60-mesh particles after drying. Mix evenly with the essential oil microemulsion prepared in step (1) at a ratio of 1:3 (w / w) to obtain essential oil microcapsules.

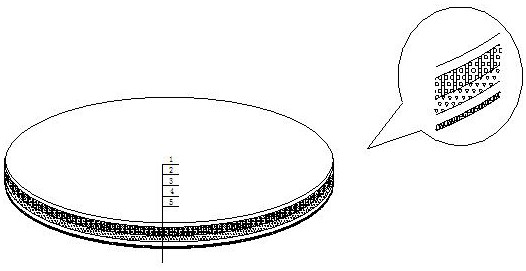

[0034] (3) Preparation of concentrated active packaging stickers: uniformly mix the essential oil microcapsules prepared in step (2) with the adhesive in a ratio of 1:2 (w / w) to obtain a coating solution containing essential oils, which is passed through a continuous coating machine Coated on the self-adhesive base material...

Embodiment 2

[0036] (1) Preparation of microemulsion: Mix plant essential oil and ultrapure water at a ratio of 6:4 (v / v), and gradually add Tween 80 and absolute ethanol at a ratio of 3:1 (v / v) at 50°C. v) Surfactants mixed in the same ratio and stirred until clear and transparent, it is an essential oil microemulsion.

[0037] (2) Preparation of microcapsules: Spray a uniform mixture of corn starch and β-cyclodextrin in a ratio of 70:5 (w / w) with 80% absolute ethanol, and obtain 80-mesh particles after drying. Mix evenly with the essential oil microemulsion prepared in step (1) at a ratio of 2:1 (w / w) to obtain essential oil microcapsules.

[0038] (3) Preparation of concentrated active packaging stickers: uniformly mix the essential oil microcapsules prepared in step (2) with the adhesive in a ratio of 1:2 (w / w) to obtain a coating solution containing essential oils, which is passed through a continuous coating machine Coated on the self-adhesive base material and compounded with PET t...

Embodiment 3

[0040] (1) Preparation of microemulsion: Mix plant essential oil and ultrapure water at a ratio of 4:5 (v / v), and gradually add Tween 80 and absolute ethanol at a ratio of 1:3 (v / v) at 50°C. v) Surfactants mixed in the same ratio and stirred until clear and transparent, it is an essential oil microemulsion.

[0041] (2) Preparation of microcapsules: Spray a uniform mixture of cornstarch and β-cyclodextrin in a ratio of 60:3 (w / w) with 100% absolute ethanol, and obtain 60-mesh particles after drying. Mix evenly with the essential oil microemulsion prepared in step (1) at a ratio of 1:3 (w / w) to obtain essential oil microcapsules.

[0042] (3) Preparation of concentrated active packaging stickers: uniformly mix the essential oil microcapsules prepared in step (2) with the adhesive at a ratio of 1:1 (w / w) to obtain a coating solution containing essential oils, which is passed through a continuous coating machine Coated on the self-adhesive base material and compounded with PET t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com