Polishing solution for stainless steel surface machining

A technology of surface processing and polishing fluid, which is applied in the field of materials, can solve problems such as poor surface finish, unfavorable processing accuracy, and deep damage layer, and achieve the effects of low cost, avoiding burns, and high polishing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

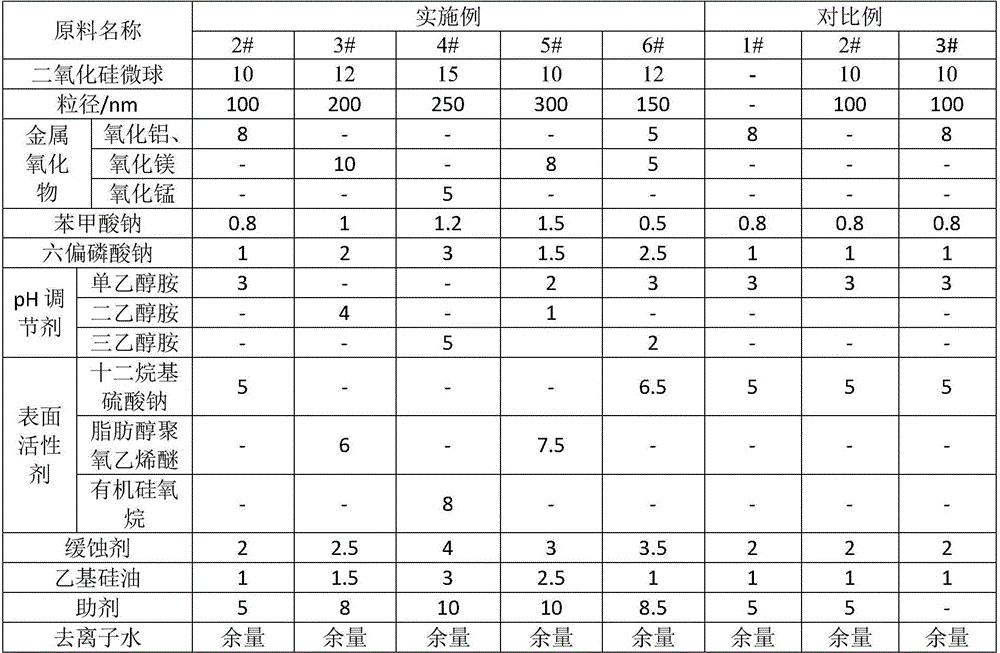

Examples

Embodiment 1

[0030] A polishing liquid for stainless steel surface processing, in parts by weight, consisting of the following components:

[0031] 10 parts of modified silica microspheres, 8 parts of metal oxides, 0.5 parts of sodium benzoate, 1 part of sodium hexametaphosphate, 3 parts of pH regulator, 5 parts of surfactants, 3 parts of corrosion inhibitors, 1 part of ethyl silicone oil Parts, 5 parts of additives, balance of deionized water,

[0032] The auxiliary agent is composed of the following parts by weight: 1 part of sodium alginate, 1 part of carrageenan, 2 parts of light calcium carbonate, 7 parts of sodium carboxymethyl cellulose, 2 parts of antioxidant 1010, 4 parts of benzyl alcohol, polyethylene Alcohol 2 parts; the balance of deionized water, the preparation method is: mix polyvinyl alcohol and carrageenan into deionized water, stir and dissolve at 70℃, add benzyl alcohol, continue to stir for 0.5h, and then add the remaining components , Stir the reaction for 2-3h;

[0033] T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com