Rtechnique for extracting chitin in high molecular weight

A high molecular weight, chitin technology, applied in the fields of bioengineering, polymer compounds and chemical industry, can solve the problems of low relative molecular weight of chitin, high cost of EDTA, cumbersome production process, etc., and achieve mild performance and simplified production process. , the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

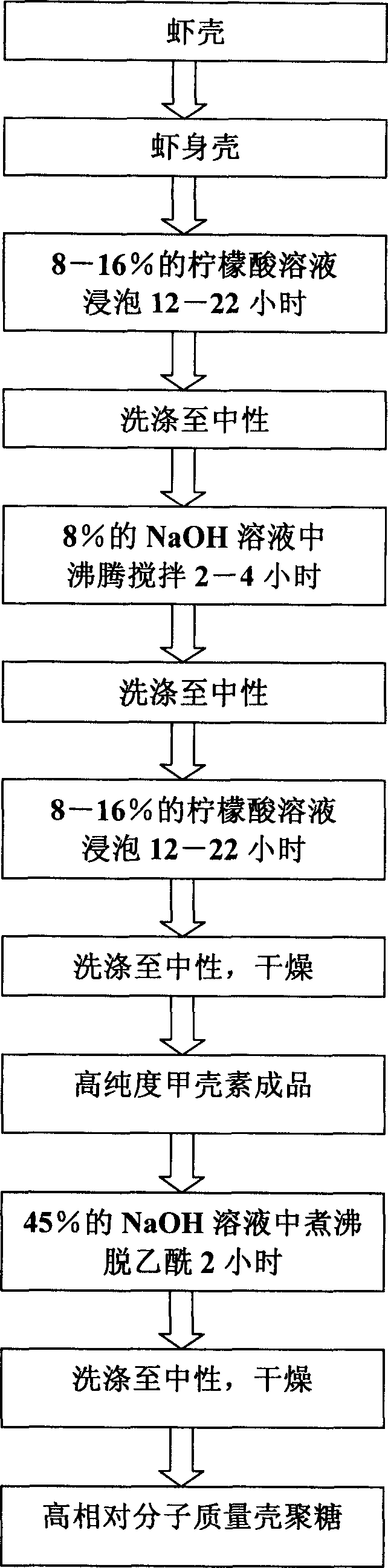

Method used

Image

Examples

Embodiment 1

[0013] 10 kg of separated, screened and cleaned shrimp shells were air-dried at about 80°C for 5-8 hours, then soaked in 8% citric acid solution at room temperature for 22 hours, filtered, washed with water until neutral, and dried. Then add 8% NaOH solution, boil and stir for 2 hours, filter, wash with water until neutral, and spin dry. Add 8% citric acid solution again, soak at room temperature for 22 hours, filter, spin dry, wash with water until neutral, and blow dry at 80°C to obtain white or slightly flesh-colored chitin finished product. Add the resulting chitin product into 45% NaOH solution, soak and stir at 65°C for 15 hours, carry out deacetylation treatment twice, filter, wash with water until neutral, spin dry, and blow dry at 80°C to obtain white, Translucent, slightly pearly chitosan products, the degree of deacetylation DD is greater than 80%, and the molecular weight is higher than 180,000.

Embodiment 2

[0015] 10kg of separated, screened and cleaned shrimp shells were air-dried at about 80°C for 5-8 hours, then soaked in 16% citric acid solution at room temperature for 12 hours, filtered, washed with water until neutral, and dried. Then add 8% NaOH solution, boil and stir for 3 hours, filter, wash with water until neutral, and spin dry. Add 16% citric acid solution again, soak at room temperature for 12 hours, filter, spin dry, wash with water until neutral, and blow dry at 80°C to obtain white or slightly flesh-colored chitin finished product. Add the resulting chitin product into 45% NaOH solution, soak and stir at 65°C for 15 hours, carry out deacetylation treatment twice, filter, wash with water until neutral, spin dry, and blow dry at 80°C to obtain white, Translucent, slightly pearly chitosan products, the degree of deacetylation DD is greater than 80%, and the molecular weight is higher than 180,000.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com