Preparation method and application of rice hull/straw feed additive

A technology of straw feed and additives, applied in application, animal feed, animal feed, etc., can solve the problems of short digestive tract, lack of digestion, difficult digestion and absorption, etc., and achieve the effect of enhancing palatability, low cost, and comprehensive nutrition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] The preparation method of the rice husk / stalk feed additive of the present embodiment is as follows:

[0051] It is prepared from the following raw materials in parts by weight:

[0052] Rice husk / straw 65 Corn 20 Soybean meal 6

[0053] Combined enzyme 0.05 oil bran 5;

[0054] The combined enzyme used is mixed by β-glucanase: xylanase: cellulase in equal weight parts, wherein: β-glucanase, xylanase activity>1000IU / ml, cellulose Enzyme activity>3000IU / ml;

[0055] Its preparation process is as follows:

[0056] (1) Prepare materials: according to the above-mentioned weight ratio, get each raw material respectively, for subsequent use;

[0057] (2) Rice husk / straw pretreatment: remove the sundries in the rice husk, cut the straw into 1-2 cm small pieces, and make them into predictions for later use;

[0058] (3) Ammonification treatment: soak the spare material, control the water content at 30%, send it into the ammoniation furnace, and close the furnace door; then...

Embodiment 2

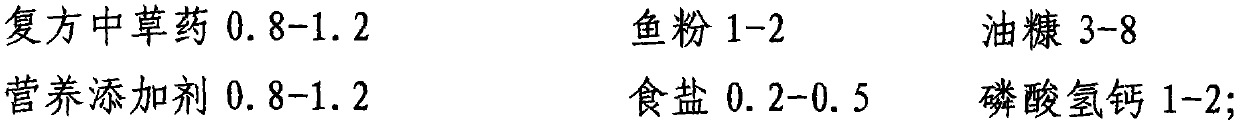

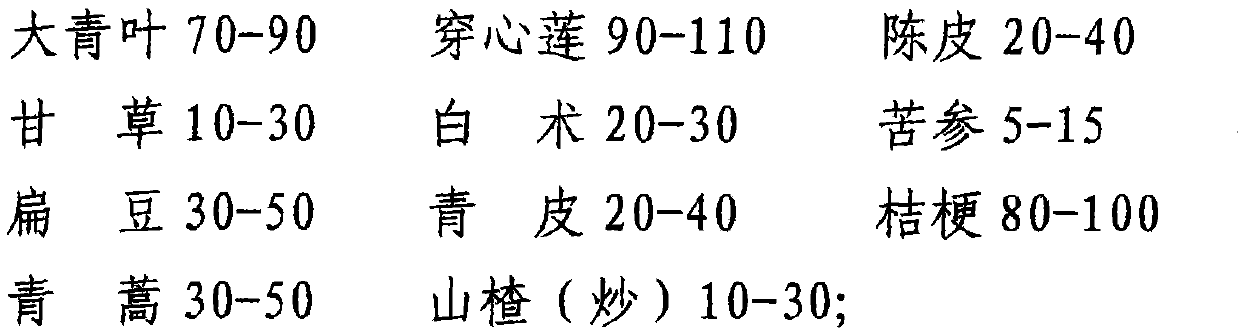

[0064] In this example, the rice husk / straw feed additive prepared in Example 1 is used to prepare rice husk / straw chicken feed. The rice husk / straw chicken feed is prepared from the following raw materials in parts by weight:

[0065] Rice husk / straw feed additive 65 corn 18 soybean meal 6.3 oil bran 5 fish meal 2

[0066] Calcium hydrogen phosphate 1.4 Nutritional additive 1.0 Salt 0.3 Compound Chinese herbal medicine 1;

[0067] The nutritional additives used are 0.085% calcium, 0.05% phosphorus, 0.005% magnesium, 0.0007% copper, 0.0055% iron, 0.007% zinc, 0.0055% manganese, 0.015% yeast selenium, and 0.015% multivitamin %, choline 0.015%, methionine 0.075%, lysine 0.03% powder mixture;

[0068] The used compound Chinese herbal medicine is made up of following Chinese medicines by weight:

[0069]

[0070] Its preparation process is as follows:

[0071] (1) Prepare materials: according to the above-mentioned weight ratio, get each raw material respectively, for subseq...

Embodiment 3

[0079] This example uses the rice husk / straw feed additive prepared in Example 1 to prepare rice husk / straw duck feed, which is prepared from the following raw materials by weight:

[0080] Rice husk / straw feed additive 68 corn 10 soybean meal 13 fish meal 2 salt 0.3

[0081] Calcium hydrogen phosphate 1.5 Heavy calcium powder 3 Nutritional additives 1.2 Compound Chinese herbal medicine 1;

[0082] The nutritional additive contains 0.08-0.09% of calcium element, 0.04-0.06% of phosphorus element, 0.004-0.006% of magnesium element, 0.0006-0.0008% of copper element, 0.005-0.006% of iron element, 0.006-0.008% of zinc element, Manganese element 0.005-0.006%, yeast selenium 0.01-0.02%, multivitamin 0.01-0.02%, choline 0.01-0.02%, methionine 0.1-0.15%, lysine 0.02-0.04% powdery mixed substance;

[0083] Described compound Chinese herbal medicine is made up of following Chinese medicine by weight:

[0084]

[0085] Its preparation process is as follows:

[0086] (1) Prepare mate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Active | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com