Ultramicro material grinder

A pulverizer and material technology, which is applied in the field of machinery, can solve the problems such as the cutting edge cannot be reached and the fineness of pulverization is not enough, so as to achieve good pulverization effect and increase the mutual friction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

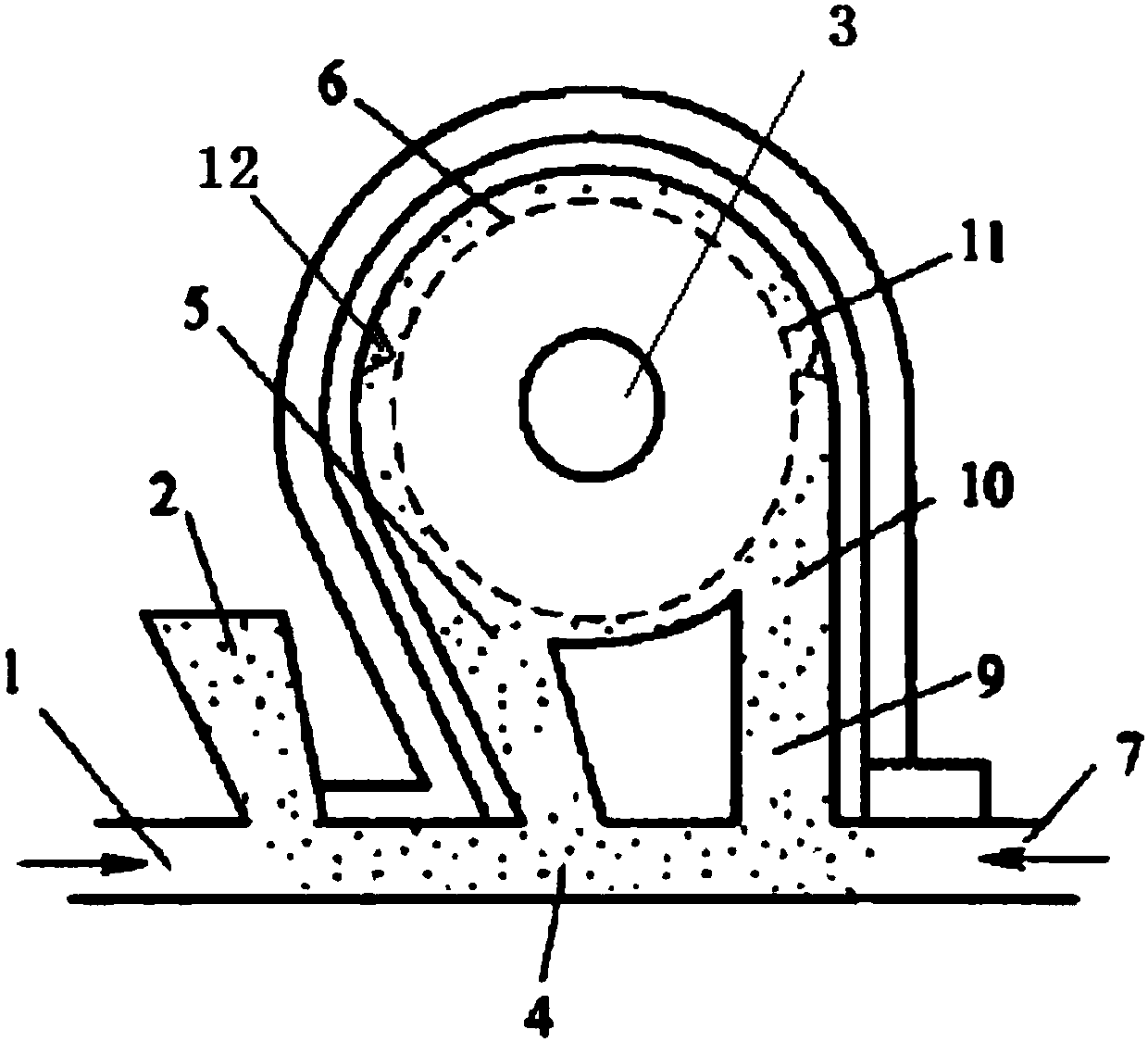

[0007] The present invention is specifically described below in conjunction with accompanying drawing, as figure 1 As shown, the present invention comprises left nozzle 1, right nozzle 7, and between left nozzle 1 and right nozzle 7 is impact cavity 3; Feed inlet 2 is arranged between left nozzle 1 and impact cavity 3; Described impact cavity 3 and conduit 4 It communicates with the downcomer 9, and both the conduit 4 and the downcomer 9 communicate with the grading chamber 6, the grading chamber 6 is annular, and the inner wall is provided with a screen hole 11; the triangular cutter 12 is symmetrically arranged on the wall of the grading chamber 6 The inner diameter of the upper conduit 5 is greater than the inner diameter of the lower conduit 9, and the length of the upper conduit 5 is less than the length of the lower conduit 9.

[0008] A material receiving plate 3 is arranged axially in the middle of the grading chamber, and the material receiving plate 3 is arranged obl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com