Method for improving raw material mixing efficiency by optimizing frit mixing machine

A technology of mixing efficiency and mixers, applied in mixers, chemical instruments and methods, mixer accessories, etc., can solve problems such as uneven mixing of batch materials, refractory materials in melting pools, etc., to slow down segregation, increase friction, The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

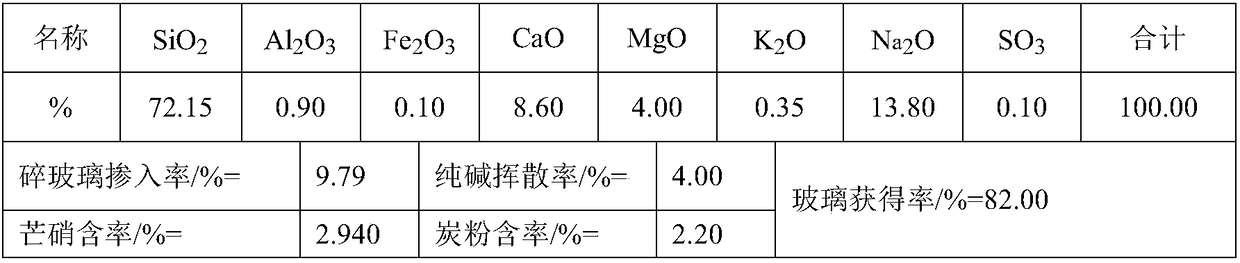

Embodiment 1-8

[0022] Based on optimizing the glass frit mixer to improve the method for raw material mixing efficiency, comprising the steps:

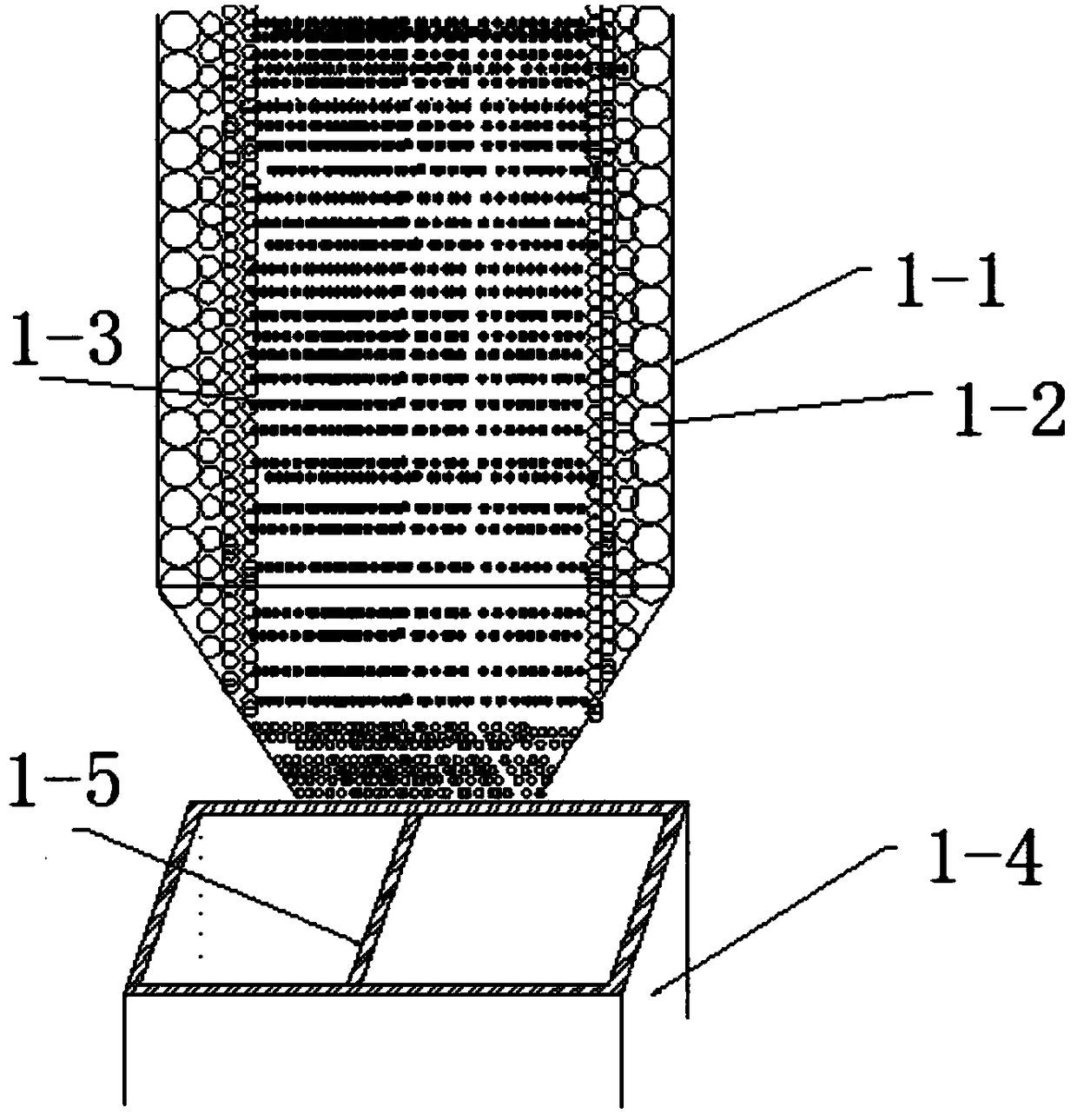

[0023] 1) figure 1 It is the feed port at the upper end of the intermediate warehouse and the connecting channel. figure 1 Among them, 1-1 is the main body of the intermediate warehouse, 1-2 is the large granular material in the warehouse, 1-3 is the small granular material in the warehouse, 1-4 is the feeding port at the upper end of the connecting channel, and 1-5 is the upper end of the connecting channel. The baffle, the angle between the baffle and the horizontal plane is σ 1 =90°~150°;

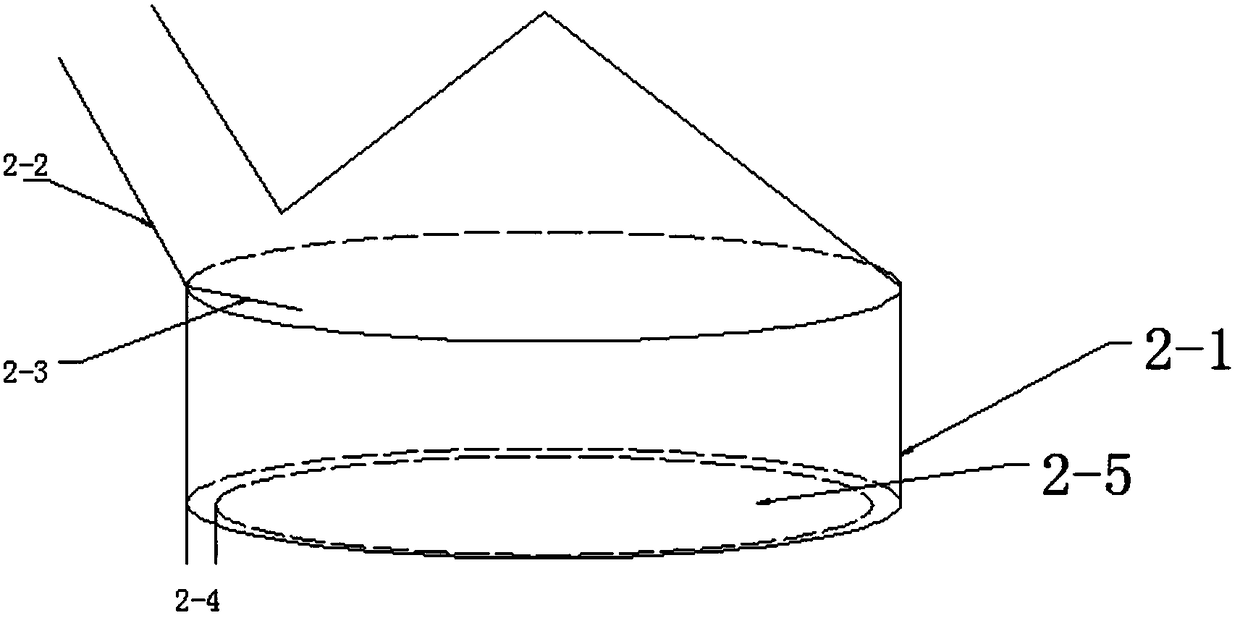

[0024] 2) figure 2 It is the outlet of the mixer and the lower end of the connecting channel. figure 2 Among them, 2-1 is the main body of the mixer, 2-2 is the outlet at the lower end of the connecting channel, 2-3 is the baffle set at the lower end of the connecting channel, and the angle between the baffle and the side wall of the mixer is σ 2 = 0°~6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com