Water-based inorganic floor coating and preparation method thereof

A floor coating, inorganic technology, applied in the direction of coating, etc., can solve the problems of high brittleness of the coating film, easy cracking of the coating film, high curing temperature, etc., and achieve the effect of improving water retention, scrub resistance and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

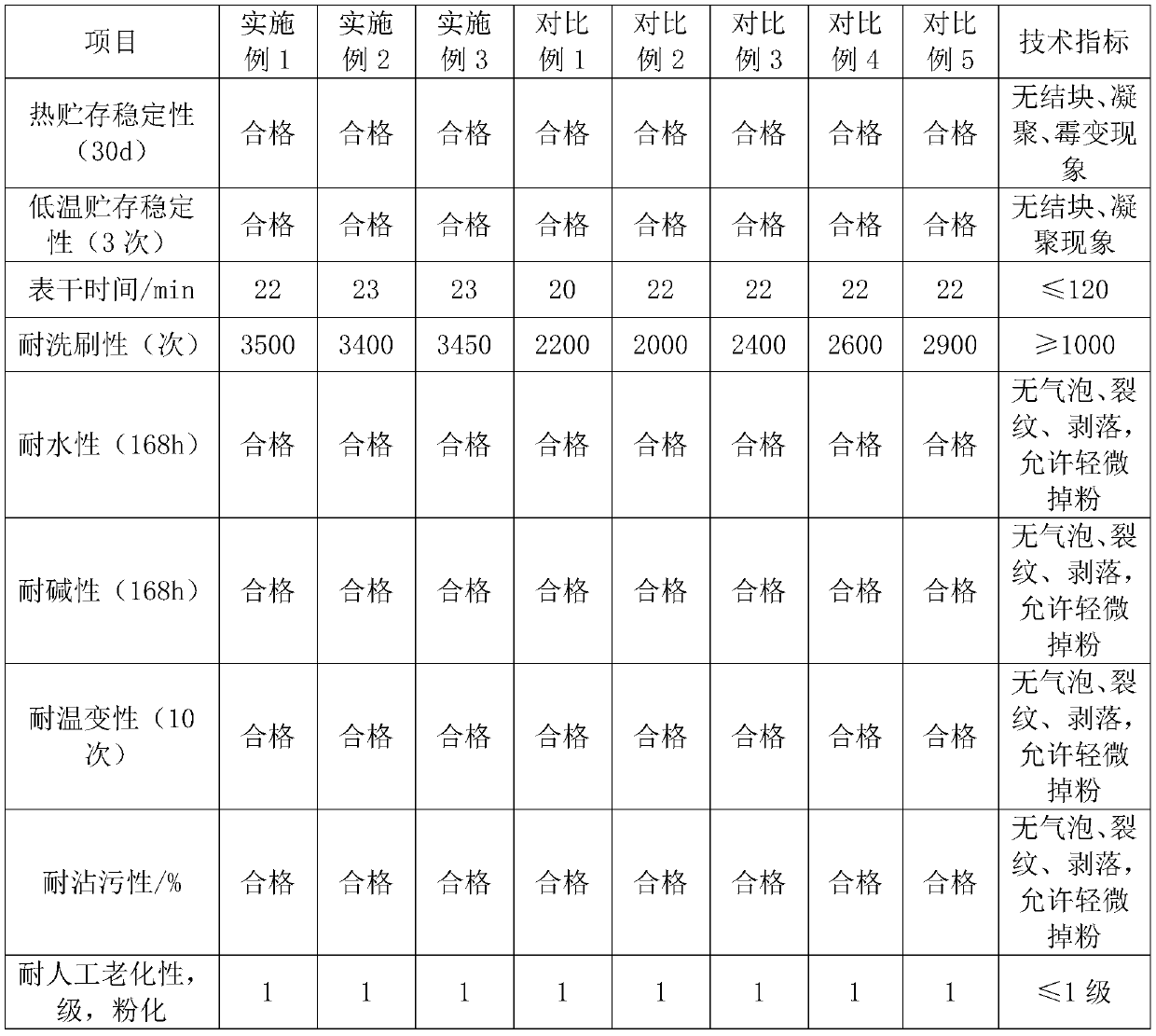

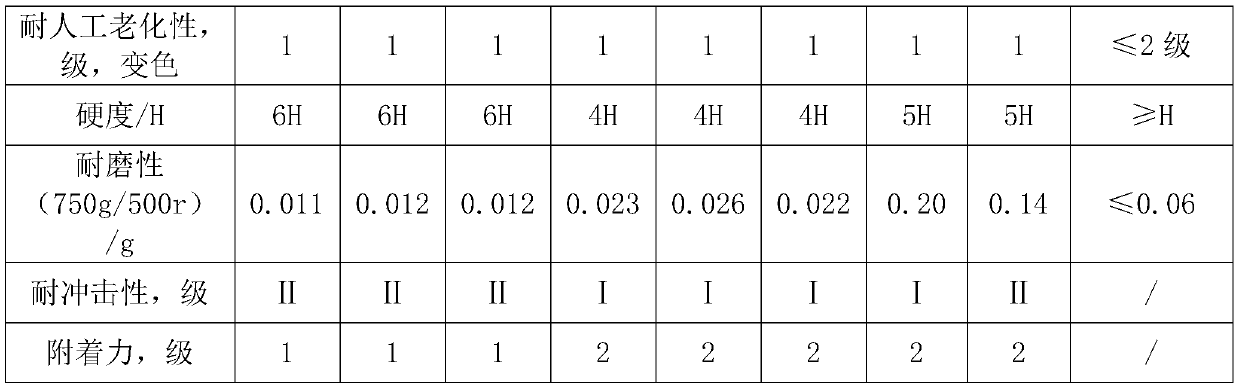

Examples

preparation example 1

[0043] Preparation example 1 of organic sepiolite: a. Take 50kg of sepiolite powder, add it to 200kg of water, and stir at a speed of 2000r / min for 40min at a temperature of 50°C to obtain a sepiolite dispersion;

[0044] b. Add 8kg of dioctadecyldimethylammonium bromide to the sepiolite dispersion, stir for 1h at a speed of 800r / min, then add 3kg of stearic acid amide, and stir for 20min at a speed of 800r / min , to obtain a suspension;

[0045] c. Centrifuge the suspension at a speed of 5000 r / min for 3 minutes, remove the supernatant, and obtain a precipitate; dry the precipitate at a temperature of 90° C. for 12 hours, and pulverize through a 200-mesh sieve to obtain organic sepiolite.

preparation example 2

[0046] Preparation example 2 of organic sepiolite: a. Take 50kg of sepiolite powder, add it to 250kg of water, and stir at a speed of 2000r / min for 50min at a temperature of 55°C to obtain a sepiolite dispersion;

[0047] b. Add 9kg of dioctadecyldimethylammonium bromide to the sepiolite dispersion, stir for 1.5h at a speed of 800r / min, then add 4kg of stearic acid amide, and stir at a speed of 800r / min 25min, obtain suspension;

[0048] c. Centrifuge the suspension at a speed of 5500 r / min for 4 minutes, remove the supernatant, and obtain a precipitate; dry the precipitate at a temperature of 90° C. for 12 hours, and pulverize through a 200-mesh sieve to obtain organic sepiolite.

preparation example 3

[0049] Preparation example 3 of organic sepiolite: a, take 50kg of sepiolite powder, add it to 300kg of water, and stir for 60min at a speed of 2000r / min at a temperature of 60°C to obtain a sepiolite dispersion;

[0050] b. Add 10kg of dioctadecyldimethylammonium bromide to the sepiolite dispersion, stir for 2 hours at a speed of 800r / min, then add 5kg of stearic acid amide, and stir for 30min at a speed of 800r / min , to obtain a suspension;

[0051] c. Centrifuge the suspension at a speed of 6000 r / min for 5 minutes, remove the supernatant to obtain a precipitate; dry the precipitate at a temperature of 90° C. for 12 hours, and crush through a 200-mesh sieve to obtain organic sepiolite.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com