Adhesive for corrugated board and preparation method of adhesive

A corrugated board and adhesive technology, applied in the direction of adhesive types, starch adhesives, polymer adhesive additives, etc., can solve the problem of affecting adhesive bonding strength, reducing bonding effect, and affecting production efficiency. and other problems to achieve the effect of reducing delamination, reducing cracking, and increasing curing rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

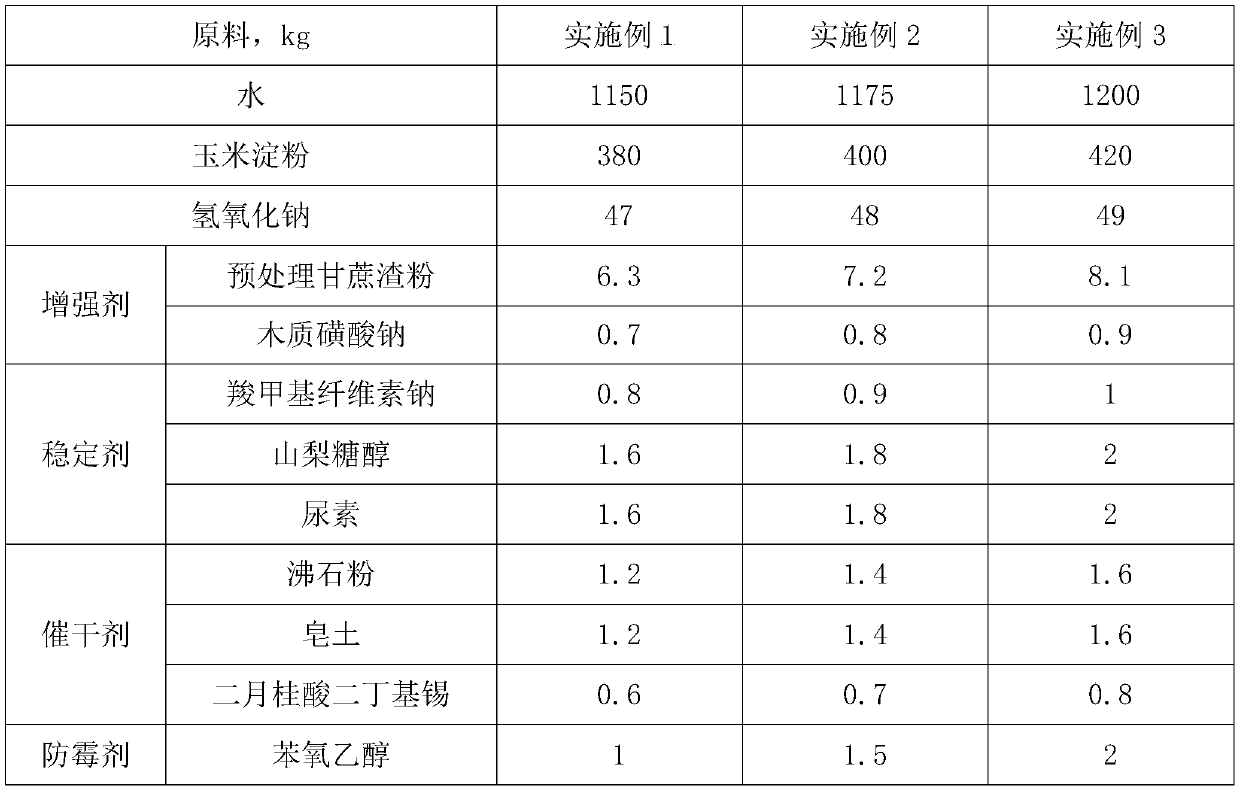

Examples

preparation example 1

[0034] Preparation example 1: take 30kg bagasse, soak it in 50kg, 25wt% sodium hydroxide solution for 10h, then clean the soaked bagasse with clear water, add 4kg sodium bisulfate and 3kg dodecyl aluminum potassium sulfate water, heated to 80°C, dried for 4 hours, crushed and sieved to obtain pretreated bagasse powder.

preparation example 2

[0035] Preparation example 2: take 35kg of bagasse, soak it in 55kg, 28wt% sodium hydroxide solution for 13h, then clean the soaked bagasse with clear water, add 5kg of sodium bisulfate and 4kg of dodecyl Aluminum potassium sulfate water, heated to 85°C, dried for 5 hours, crushed and sieved to obtain pretreated bagasse powder.

preparation example 3

[0036] Preparation example 3: take 40kg of bagasse, soak it in 60kg, 30wt% sodium hydroxide solution for 16h, then clean the soaked bagasse with clear water, add 6kg of sodium bisulfate and 5kg of dodecyl aluminum potassium sulfate water, heated to 90°C, dried for 6 hours, crushed and sieved to obtain pretreated bagasse powder.

[0037] Two, the embodiment

[0038] The cornstarch in the following examples is selected from the industrial grade corn amylase whose product number is 968452 whose content ≥ 99% is improved by Suzhou Longqing Chemical Technology Co., Ltd; .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com