Organic waste solid residue organic matter recovery device

A technology of organic waste and recovery device, which is applied to the removal of solid waste, etc., and can solve the problems of insufficient separation of organic matter, cumbersome maintenance, and inability to achieve continuous operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

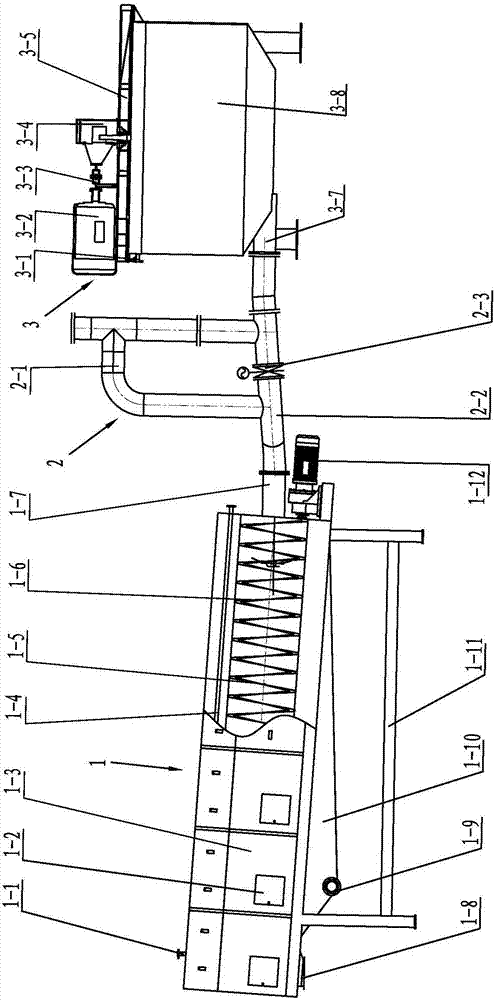

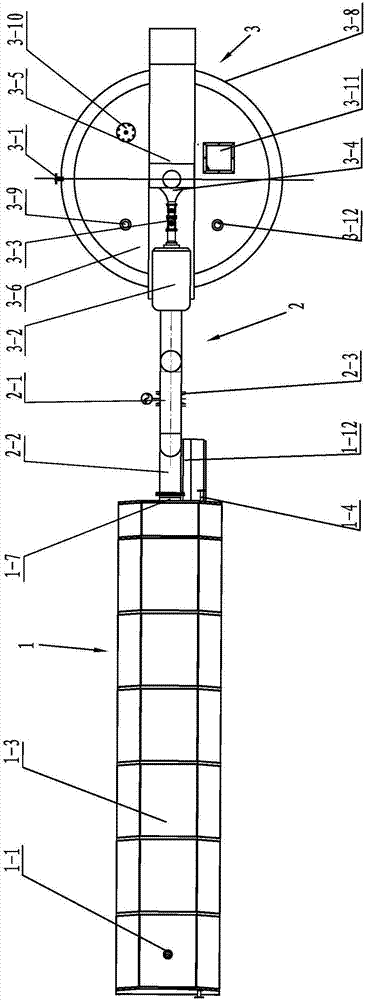

[0025] See Figure 1~3 As shown, the organic waste solid slag organic matter recovery device of the present invention includes a recovery main machine 3 , a recovery auxiliary machine 1 and a connecting pipe group 2 connected between the recovery main machine 3 and the recovery auxiliary machine 1 .

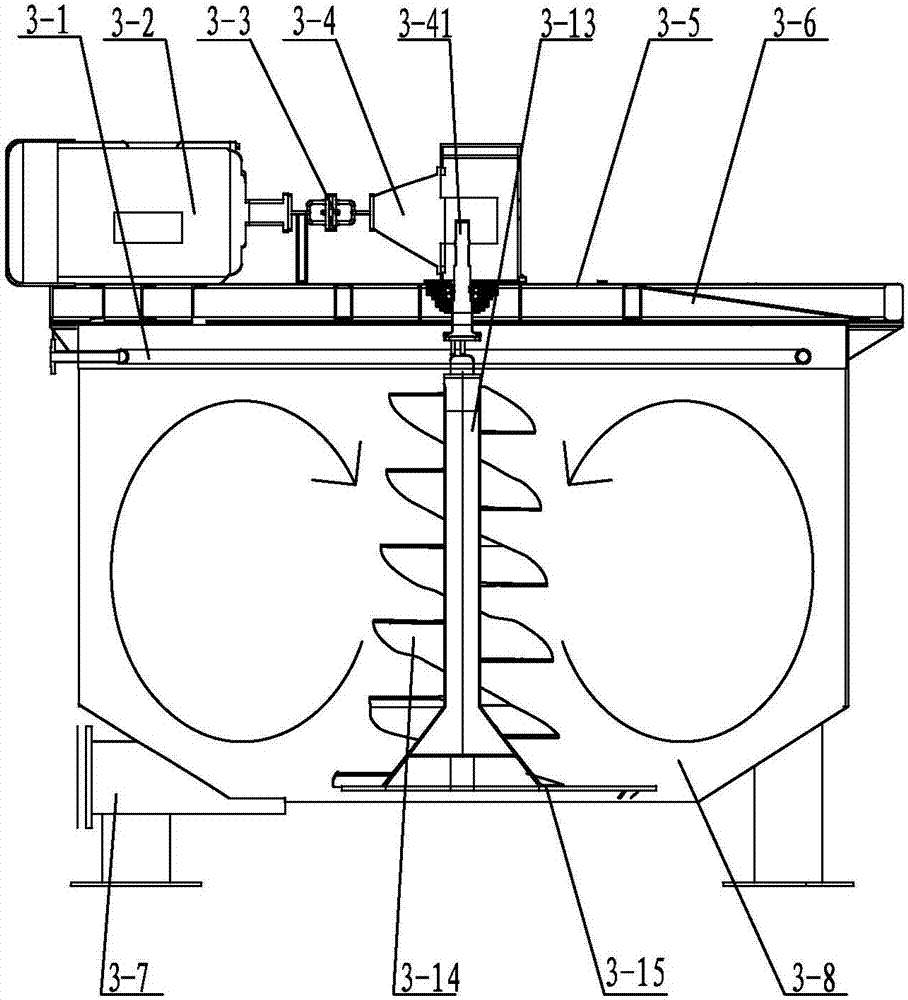

[0026] See Figure 1~3 As shown, the recovery host 3 of the present invention includes a tank body 3-8, a stirring mechanism arranged on the tank body 3-8, a supporting frame 3-5 and a cover plate 3-6 are arranged at the top of the tank body 3-8, and the bottom is provided with The discharge port 3-7 and the tank body 3-8 are made of carbon steel and a lining with wear-resistant materials, which are more suitable for organic waste slurry. The recovery host 3 can be installed on the front frame. See Figure 1~3 As shown, the cover plate 3-6 of the present invention is provided with a feed inlet 3-11, a dilution water inlet 3-10 and a radar level gauge 3-9, which can be used to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com