Treatment method and device for fluidizing and stripping high ammonia and nitrogen waste water

A treatment method, high ammonia nitrogen technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, degassed water/sewage treatment, etc., can solve high construction and operation costs, easy adhesion and scaling of packing in the tower, Ammonia nitrogen removal effect becomes poor, so as to achieve the effect of reducing equipment cleaning times, good gas-liquid mass transfer performance, and avoiding adhesion and scaling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

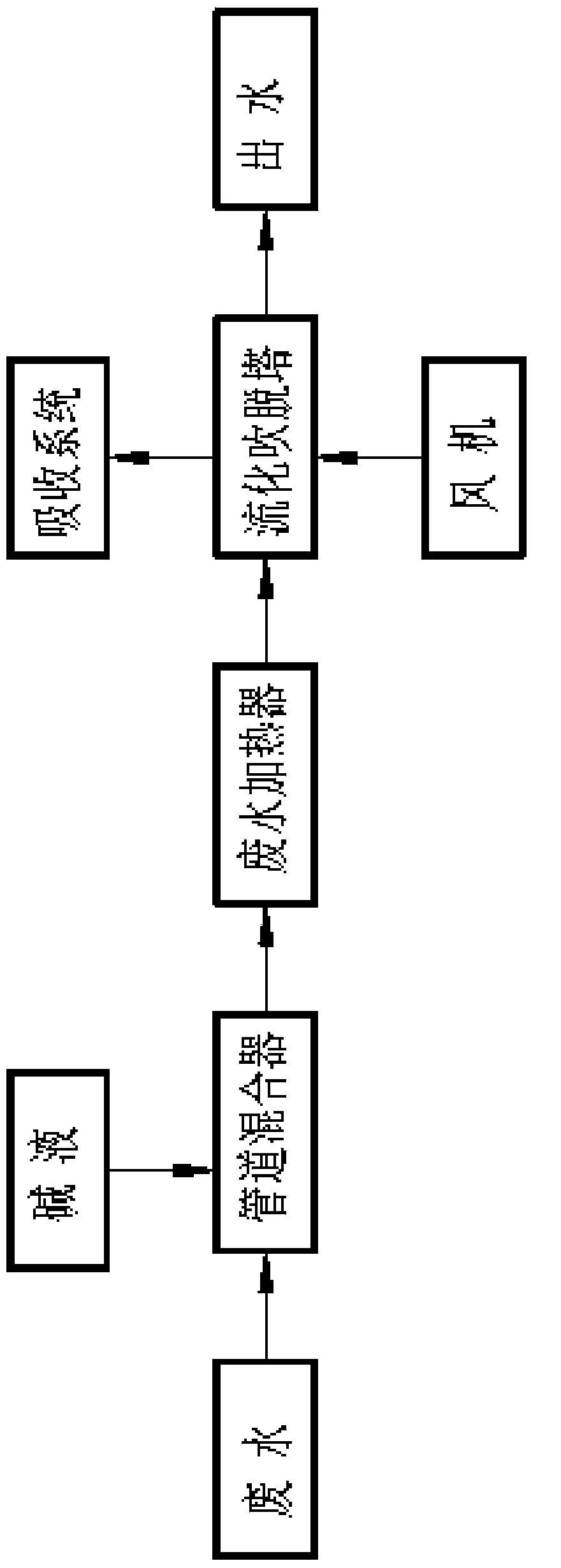

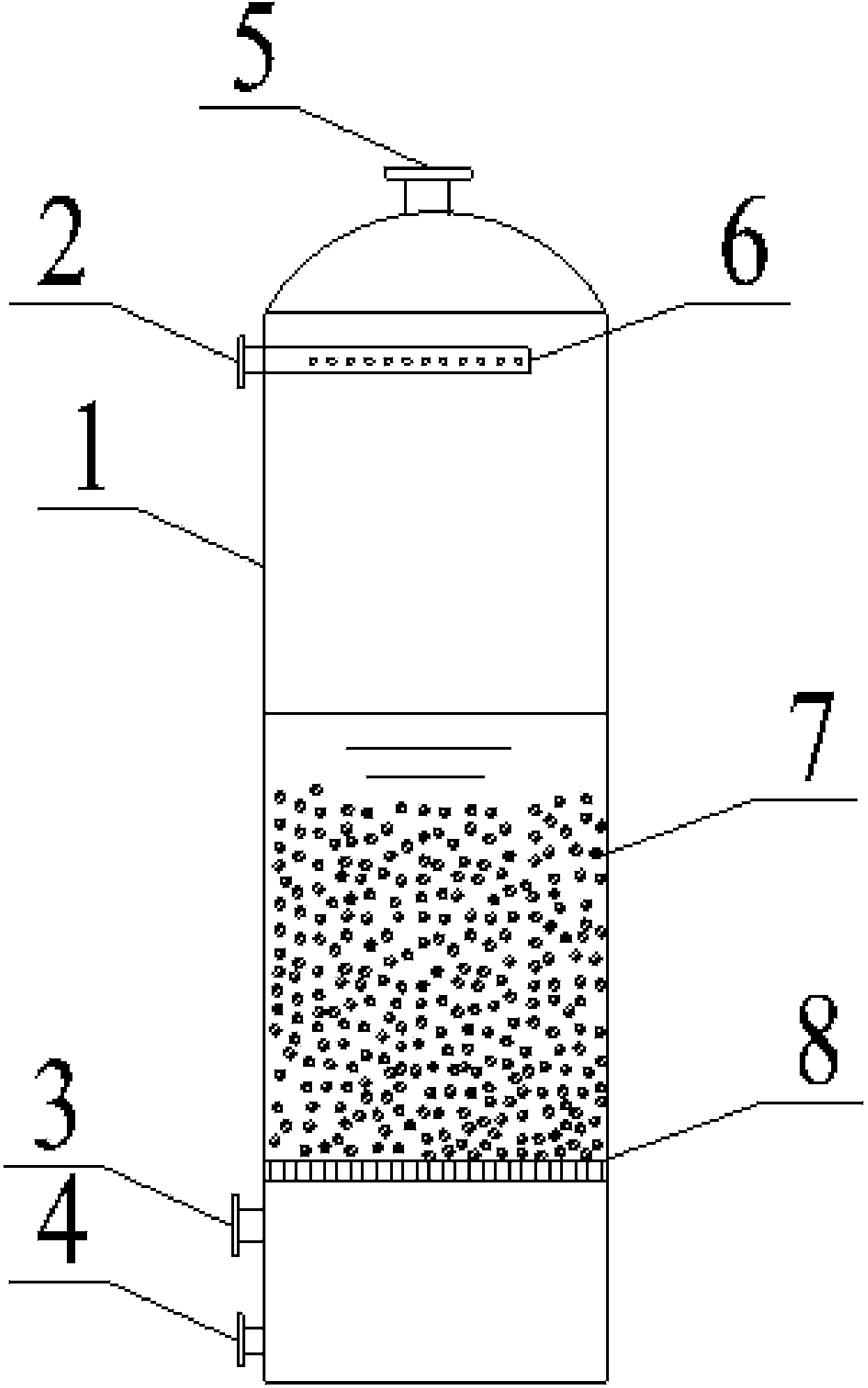

[0033] Please combine figure 1 and figure 2 , High ammonia nitrogen wastewater comes from the fecal sewage of the train feces collection system, the composition and concentration are: ammonia nitrogen 1800-2200mg / L, pH value 8-9.

[0034] Fecal sewage and lye are respectively pumped into the pipeline mixer for mixing, and the pH value of the wastewater is adjusted to 11; the mixed wastewater is sent to the wastewater heater to be heated to a temperature of 40°C; the heated wastewater is sent to the fluidized stripping tower The waste water inlet 2 on the upper part of the tower body 1 enters the fluidized stripping tower, and is evenly distributed in the tower through the waste water distributor 6; The gas distribution supporting plate 8 is evenly distributed in the tower, and the particle packing 7 is used as an absorption system in the fluidized stripping tower. Fluidized stripping tower treatment water volume is 5m 3 / h, the height of the tower is 6.4m, and the diameter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com