Workbench for clay model manufacturing

A sludge model and workbench technology, which is applied to workbenches, manufacturing tools, cleaning methods using gas flow, etc., can solve the problem that sludge is not easy to clean, achieve convenient cleaning, prevent adhesion to the surface of the airbag, and speed up heat transfer. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below by means of specific embodiments:

[0016] The reference signs in the accompanying drawings of the specification include:

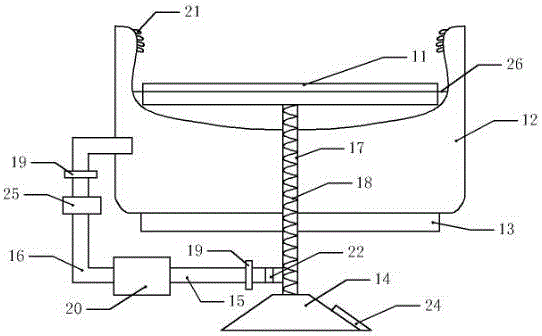

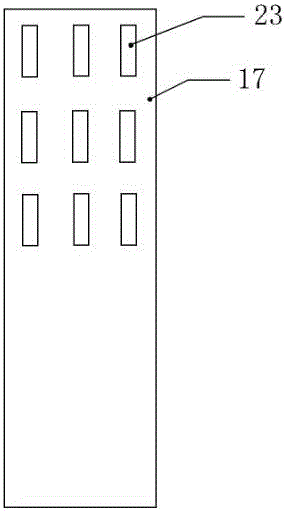

[0017] Workbench 11, air bag 12, turntable 13, base 14, exhaust pipe 15, exhaust pipe 16, rotating shaft 17, spring 18, one-way valve 19, air pump 20, air nozzle 21, filter screen 22, chip leakage hole 23, outlet Material door 24, refrigeration pump 25, round hoop 26.

[0018] Such as figure 1 The shown workbench 11 for making clay models includes a workbench 11 and a hollow base 14, a discharge door 24 is installed on the base 14, a drawer-type collecting box is arranged inside the base 14, and a hollow base 14 is fixedly installed on the base 14. The rotating shaft 17, the inner wall of the rotating shaft 17 is provided with a guide rail that spirally coils from top to bottom, the rotating shaft 17 communicates with the base 14, and the spring 18 that is tangent to the inner wall o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com