Nitrogen-doped carbon porous hollow carbon catalyst, preparation method thereof and application thereof

A nitrogen-doped carbon and hollow carbon technology, applied in electrical components, regenerative fuel cells, battery electrodes, etc., can solve the problems of short life and high cost of electrode materials and catalysts, and achieve the effect of improving the transfer rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

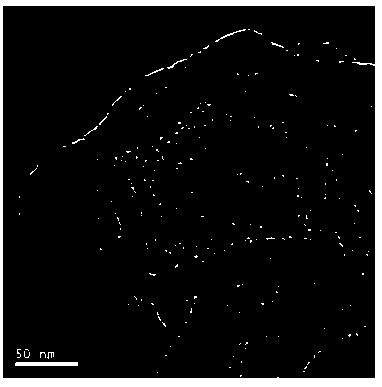

Image

Examples

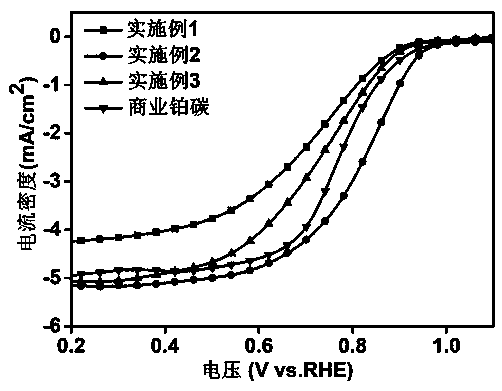

Embodiment 1

[0032] The preparation of nitrogen-doped carbon porous hollow carbon catalyst comprises the following steps:

[0033] 1) Mix 2-methylimidazole and zinc nitrate at a mass ratio of 2:1, add the mixture to methanol, stir evenly, let stand for 24 hours, filter, dry, and obtain solid powder; 2-methylimidazole The ratio of the mass of methanol to the volume of methanol is 1:20, the unit of mass is g, and the unit of volume is mL.

[0034] 2) Add 0.15 g of the solid powder obtained in step 1) into 10 mL of deionized water, and mix evenly by ultrasonic to obtain the mixed solution A. The aqueous solution of tannic acid with a concentration of 0.04 g / mL was adjusted to pH 9 with sodium hydroxide to obtain a mixed solution B.

[0035] 3) The mixture A and mixture B obtained in step 2) were mixed at a volume ratio of 0.3:1, stirred for 8 min, and then centrifuged and dried to obtain a solid powder adsorbing tannate anions.

[0036] 4) Mix the solid powder obtained in step 3) with 1-but...

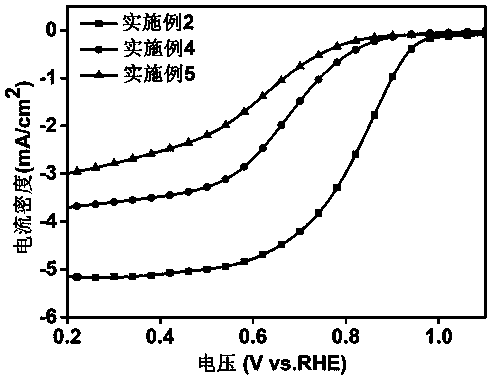

Embodiment 2

[0044] The preparation of nitrogen-doped carbon porous hollow carbon catalyst comprises the following steps:

[0045] 1) Mix 2-methylimidazole and zinc nitrate at a mass ratio of 2:1, add the mixture to methanol, stir evenly, let stand for 24 hours, filter, dry, and obtain solid powder; 2-methylimidazole The ratio of the mass of methanol to the volume of methanol is 1:20, the unit of mass is g, and the unit of volume is mL.

[0046] 2) Add 0.15 g of the solid powder obtained in step 1) into 10 mL of deionized water, and mix evenly by ultrasonic to obtain the mixed solution A. The aqueous solution of tannic acid with a concentration of 0.04 g / mL was adjusted to pH 9 with sodium hydroxide to obtain a mixed solution B.

[0047] 3) The mixture A and mixture B obtained in step 2) were mixed at a volume ratio of 0.3:1, stirred for 8 min, and then centrifuged and dried to obtain a solid powder adsorbing tannate anions.

[0048] 4) Mix the solid powder obtained in step 3) with 1-but...

Embodiment 3

[0053] The preparation of nitrogen-doped carbon porous hollow carbon catalyst comprises the following steps:

[0054] 1) Mix 2-methylimidazole and zinc nitrate at a mass ratio of 2:1, add the mixture to methanol, stir evenly, let stand for 24 hours, filter, dry, and obtain solid powder; 2-methylimidazole The ratio of the mass of methanol to the volume of methanol is 1:20, the unit of mass is g, and the unit of volume is mL.

[0055] 2) Add 0.15 g of the solid powder obtained in step 1) into 10 mL of deionized water, and mix evenly by ultrasonic to obtain the mixed solution A. The 0.04 g / mL tannic acid aqueous solution was adjusted to pH 9 with sodium hydroxide to obtain a mixed solution B.

[0056] 3) The mixture A and mixture B obtained in step 2) were mixed at a volume ratio of 0.3:1, stirred for 8 min, and then centrifuged and dried to obtain a solid powder adsorbing tannate anions.

[0057] 4) Mix the solid powder obtained in step 3) with 1-butyl-3-methylimidazolium tetr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com