Material mixing device for making bricks by using waste

A mixing device and waste technology, applied in mixers, transportation and packaging, chemical/physical processes, etc., can solve the problems of destroying the quality of finished products, affecting brick processing, and insufficient mixing of raw materials, so as to aggravate the effect and improve the mixing effect. The effect of improving material efficiency, improving mixing efficiency and mixing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below by means of specific embodiments:

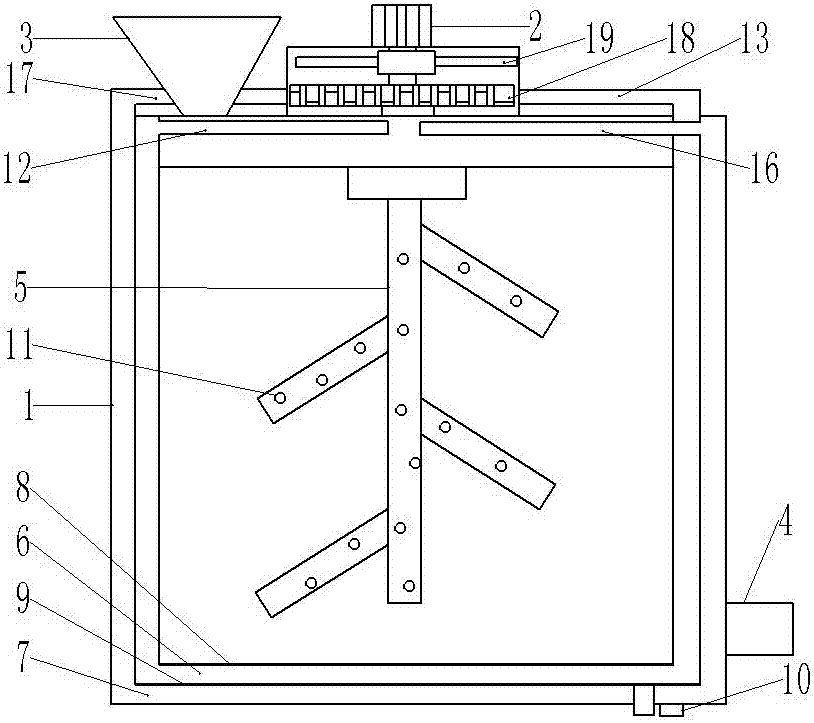

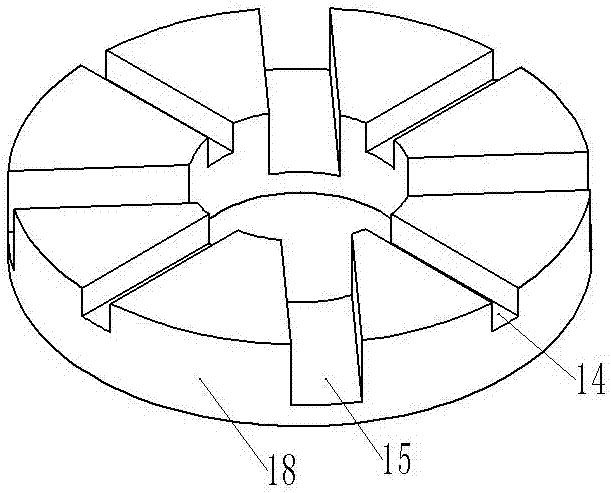

[0020] The reference signs in the drawings of the description include: mixing cylinder 1, motor 2, feed port 3, discharge port 4, stirring shaft 5, first chamber 6, second chamber 7, first elastic layer 8, Second elastic layer 9, pressure relief valve 10, air hole 11, first return pipe 12, first blowing pipe 13, first air guide groove 14, second air guide groove 15, second return pipe 16, second blowing pipe 17, disk 18, fan 19.

[0021] The embodiment is basically as figure 1 and figure 2 Shown: a waste brick mixing device, including a mixing tube 1, the top of the mixing tube 1 is provided with a feed port 3 and a motor 2 is fixed with screws, and the lower right part of the mixing tube 1 is provided with a discharge port 4 . The mixing cylinder 1 is connected with a stirring shaft 5 for rotation, and a passage is provided inside the stirring shaft 5, and the passa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com