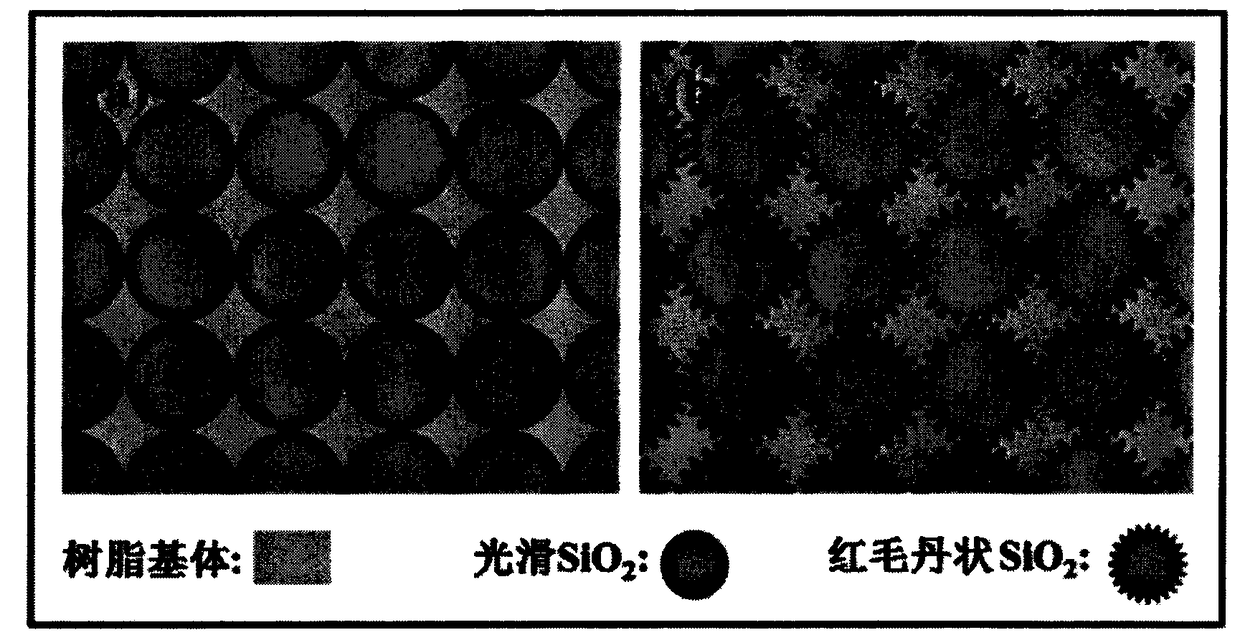

Rambutan-like SiO2-based dental composite resin and preparation method thereof

A composite resin, red hair technology, used in dental preparations, dentistry, dental prostheses, etc., can solve the problems of complex synthesis of new coupling agents and unavoidable degradation, so as to improve binding ability, reduce material breakage, increase Effect of contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] (1) Preparation of composite resin

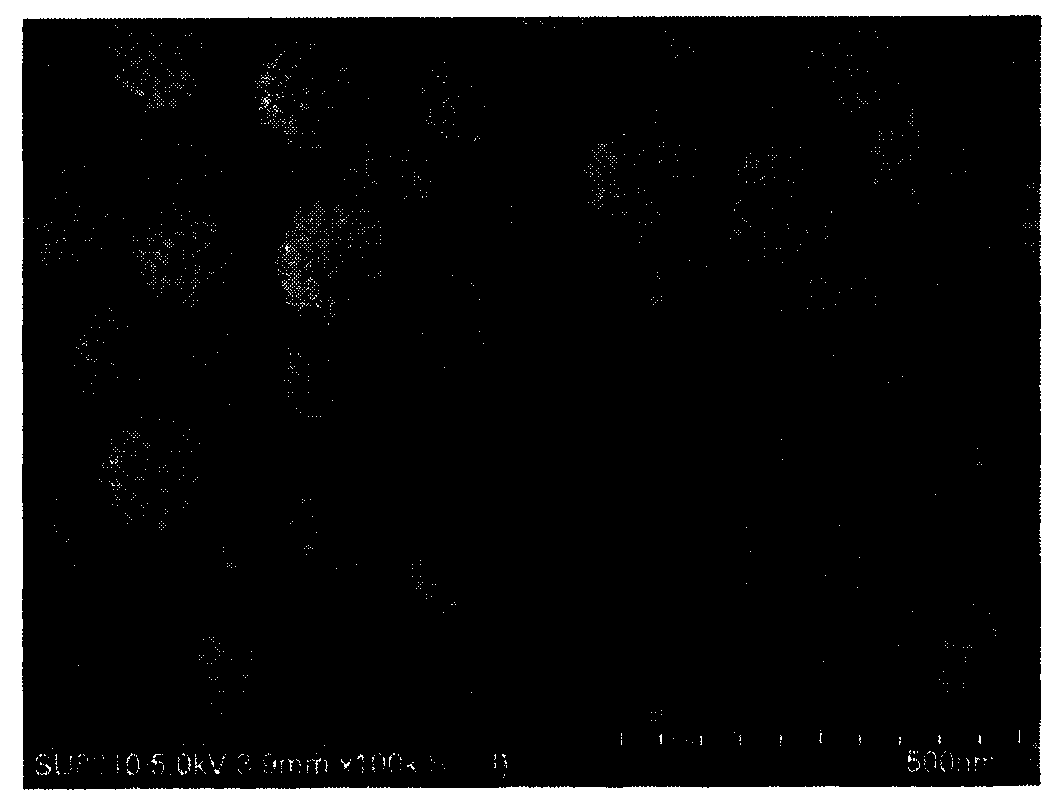

[0022] Rambutan-like SiO with a particle size of 2 μm was processed using a three-roll mill (EXAKT 80E, Germany). 2 , the resin matrix and the initiator system were uniformly mixed according to the formula shown in the following table to obtain an uncured composite resin paste, and then cured by light to obtain a dental composite resin.

[0023]

[0024] (2) Characterization of composite resin

[0025] Utilize the universal testing machine (Instron 5900, the United States) to test the bending and compressive properties of the composite resin sample. The size of the bending sample is 2mm×2mm×25mm, the span during the test is 20mm, and the pressure head speed is 0.75mm / min; The size of the compressed sample is Φ4mm×6mm, and the loading rate during the test is 1.00mm / min. The flexural strength of the prepared composite resin material is 126±5MPa, the flexural modulus is 12±0.8GPa, and the compressive strength is 317±15MPa.

Embodiment 2

[0027] (1) Preparation of composite resin

[0028] The rambutan-like SiO with a particle size of 0.5 μm was milled using a three-roll mill (EXAKT 80E, Germany). 2 , the resin matrix and the initiator system were uniformly mixed according to the formula shown in the following table to obtain an uncured composite resin paste, and then cured by light to obtain a dental composite resin.

[0029]

[0030] (2) Characterization of composite resin

[0031] The characterization method is the same as in Example 1. The bending strength of the prepared composite resin material is 145±10MPa, the bending modulus is 11±0.5GPa, and the compressive strength is 350±21MPa.

Embodiment 3

[0033] (1) Preparation of composite resin

[0034] Rambutan-like SiO with a particle size of 1 μm was milled using a three-roll mill (EXAKT 80E, Germany). 2 , the resin matrix and the initiator system were uniformly mixed according to the formula shown in the following table to obtain an uncured composite resin paste, and then cured by light to obtain a dental composite resin.

[0035]

[0036] (2) Characterization of composite resin

[0037] The characterization method is the same as in Example 1. The flexural strength of the prepared composite resin material is 122±7MPa, the flexural modulus is 9±0.6GPa, and the compressive strength is 328±14MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com