Piston braking system and braking method thereof

A braking system and piston technology, applied in the direction of brake actuators, gear shifting mechanisms, mechanical equipment, etc., can solve the problem of inability to completely cure brake wear and slip failure, and achieve the goal of increasing mutual friction and achieving stable braking. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

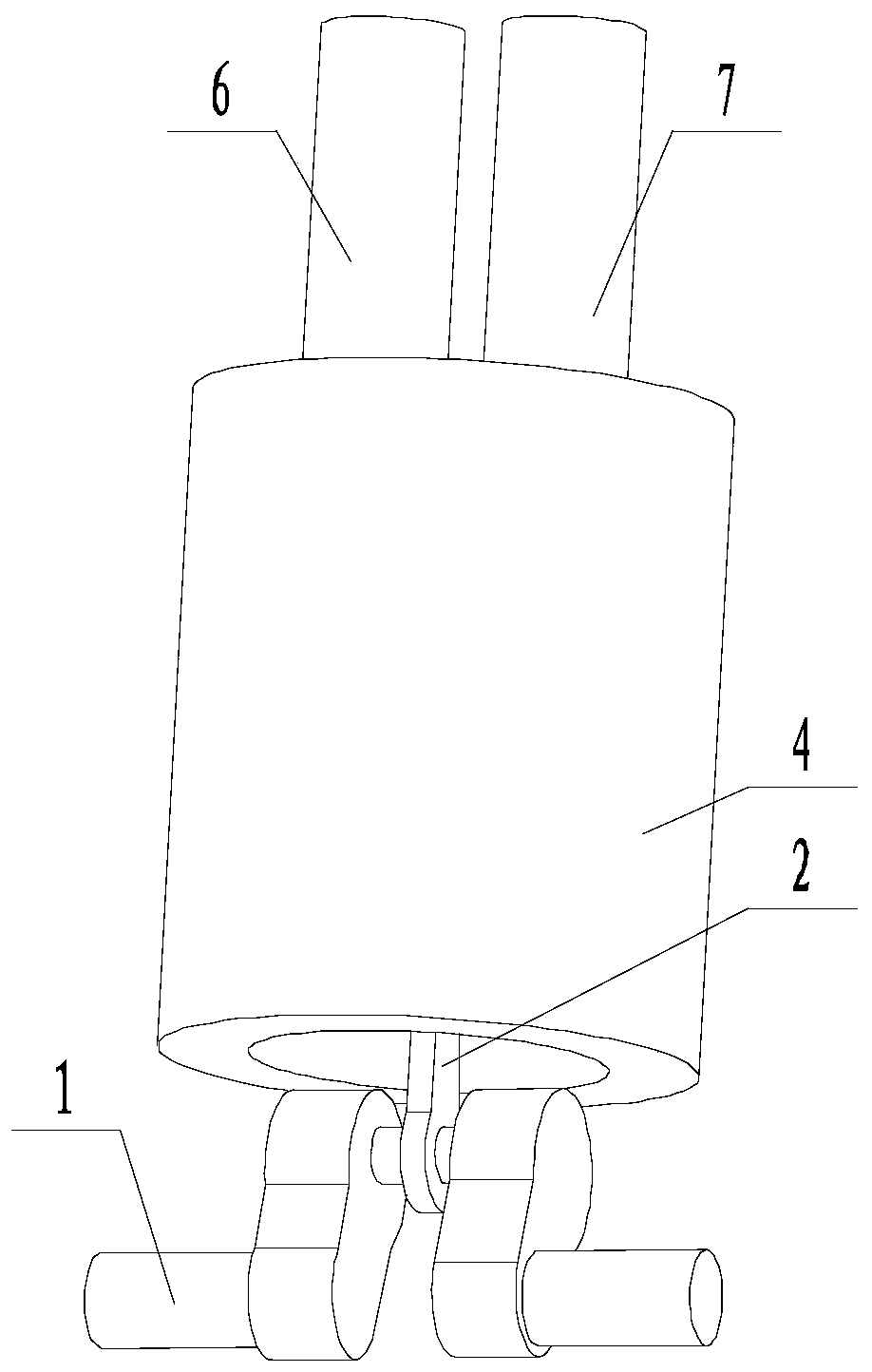

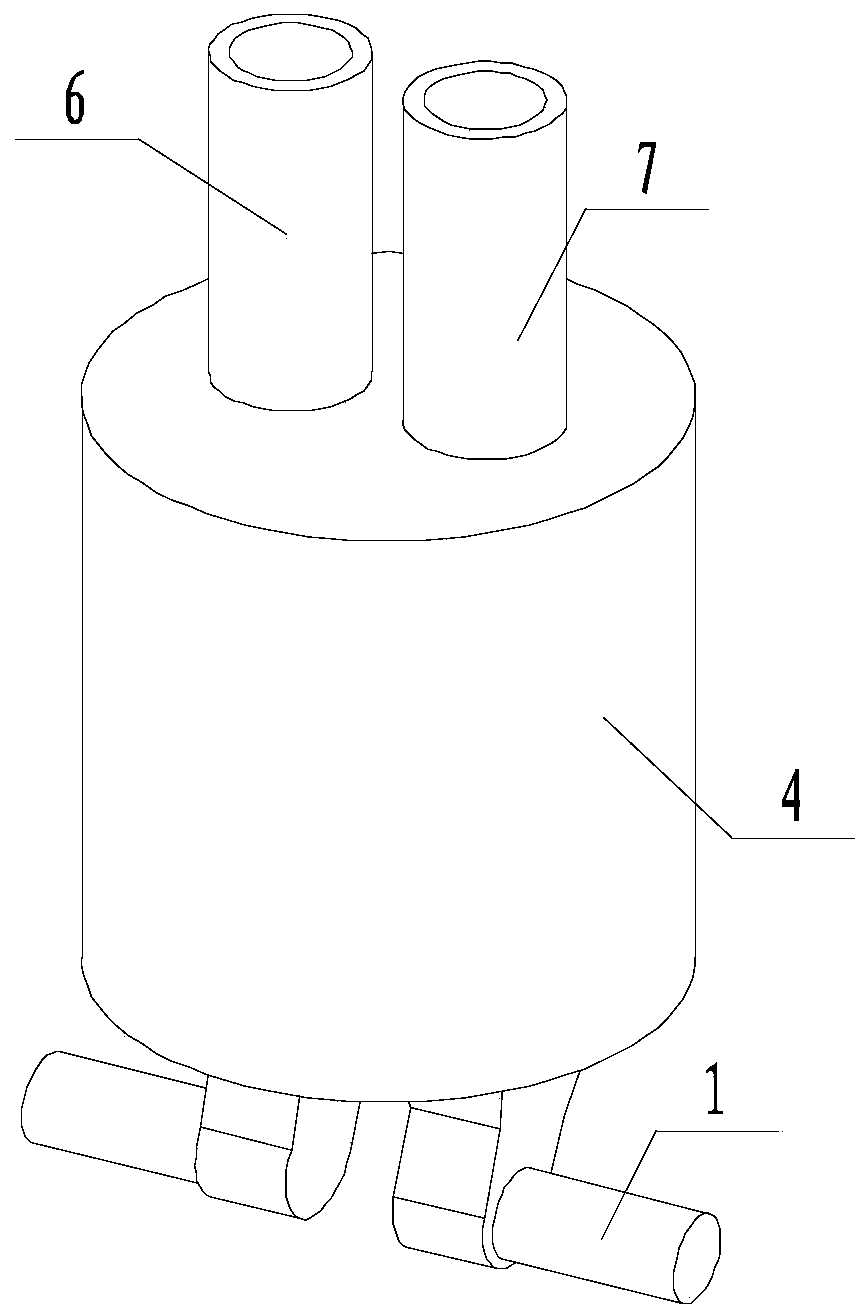

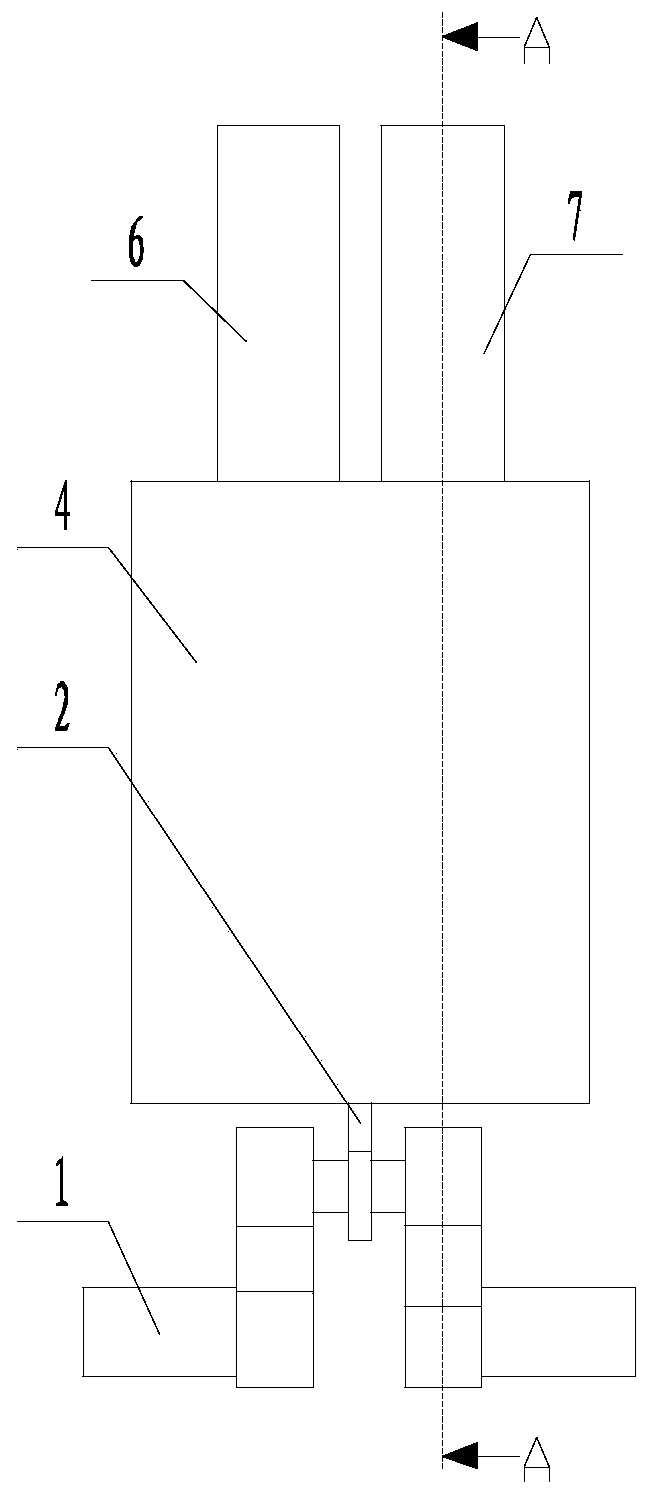

[0042] Such as Figure 1 to Figure 6 The piston brake system shown includes a transmission shaft 1 located between the starting part and the working part, and also includes a piston 3 connected to the transmission shaft 1. When the transmission shaft 1 rotates, it drives the piston 3 in the cylinder liner 4 Performing linear reciprocating motion, a pressure regulating chamber 5 is formed between the piston 3 and the cylinder liner 4, and a pressure regulating mechanism for regulating the pressure in the pressure regulating chamber 5 is also included. The pressure regulating mechanism includes an inlet pipe 6 and a discharge pipe 7 communicating with the pressure regulating chamber 5. A one-way valve 8 communicating with the pressure regulating chamber 5 is arranged in the inlet pipe 6. A one-way valve 8 communicating in a direction away from the pressure regulating chamber 5 is provided, and a regulating valve 9 is also provided in the discharge pipe 7 . The piston rod 2 of t...

Embodiment 2

[0048] Such as Figure 1 to Figure 7 In the piston braking system shown, on the basis of Embodiment 1, the pressure regulating mechanism further includes an oil cylinder 10 connected to the inlet pipe 6 and the outlet pipe 7, and the oil cylinder 10 contains hydraulic oil. The inlet pipe 6 is connected to the bottom of the oil cylinder 10; within the stroke range of the piston 3, the highest liquid level of the hydraulic oil in the oil cylinder 10 is lower than the height of the joint between the discharge pipe 7 and the oil cylinder 10. It also includes a bypass pipe 11, a bypass valve 12 is arranged on the bypass pipe 11, a regulating valve 9 is also arranged in the inlet pipe 6, and one end of the bypass pipe 11 is connected to the one-way valve 8 in the inlet pipe 6 and Between the regulating valves 9 , the other end is connected to the oil cylinder 10 ; within the travel range of the piston 3 , the maximum liquid level of the hydraulic oil in the oil cylinder 10 is lower ...

Embodiment 3

[0053] Such as Figure 1 to Figure 9 In the piston brake system shown, two pistons 3 connected to the transmission shaft 1 form a piston group; when the transmission shaft 1 rotates, the volumes of the two pressure regulating chambers 5 in the piston group always increase one by one. One is large, the other is small. It also includes a pressure sensor located in the pressure regulating chamber 5, and the pressure regulating mechanism adjusts the pressure in the pressure regulating chamber 5 according to the monitoring information of the pressure sensor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com