Multi-cylinder type water-free cleaning equipment for waste glass

A technology for waterless cleaning and waste glass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

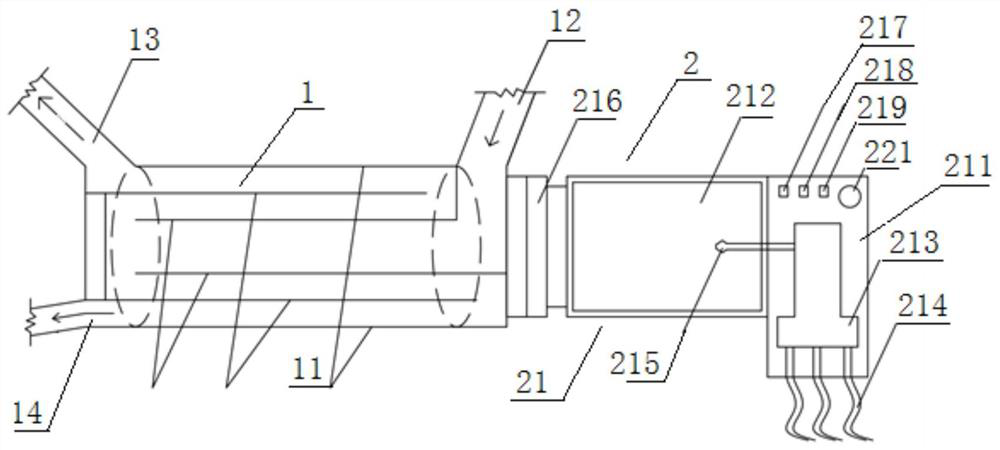

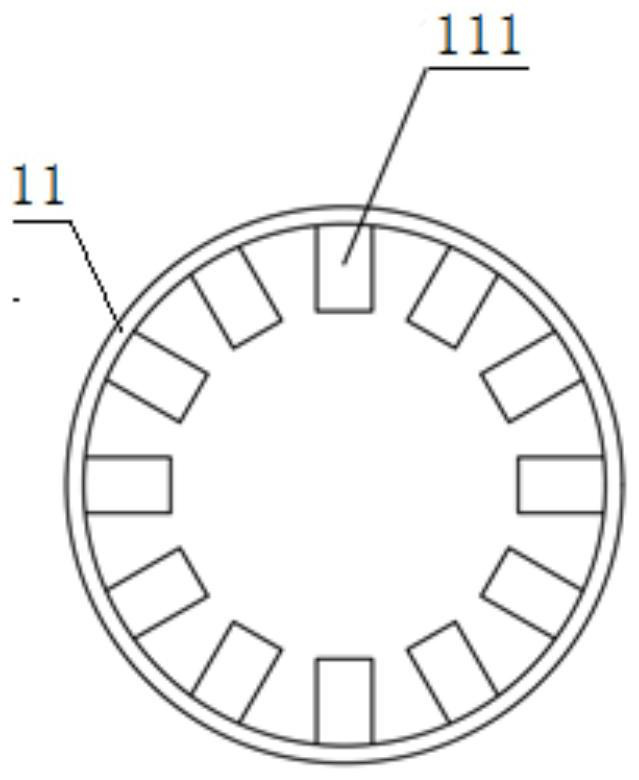

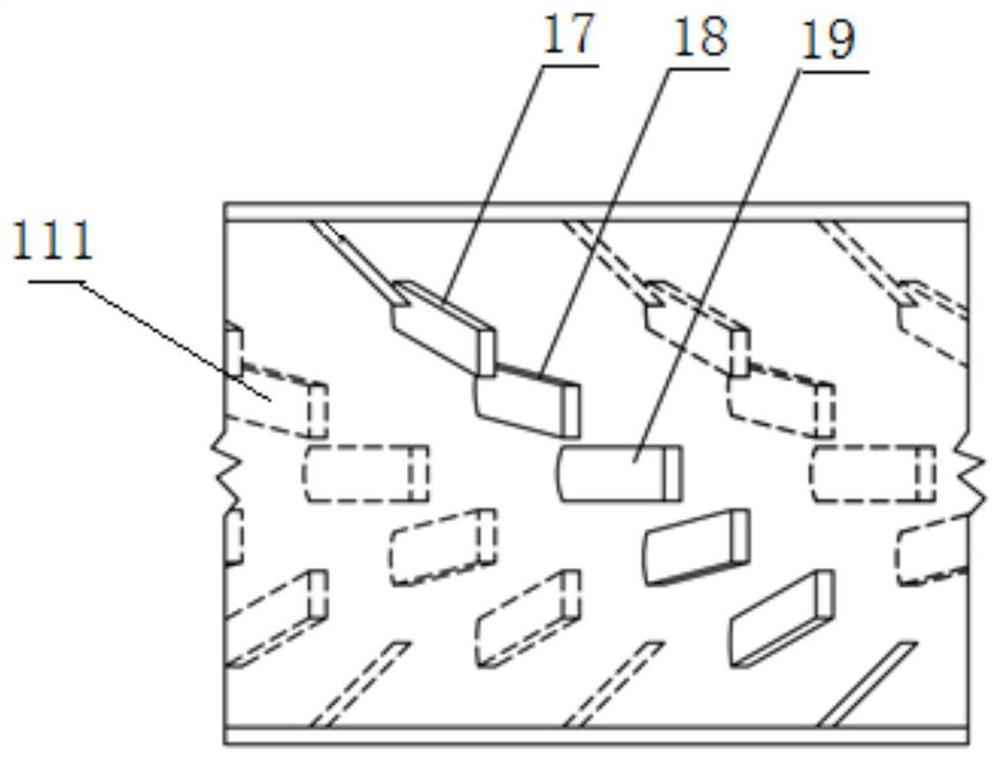

[0028] Such as Figure 1 to Figure 3 Shown is an embodiment of a multi-cylinder waste glass anhydrous cleaning equipment, which includes a cleaning and stirring device 1 for anhydrous cleaning of waste glass and a power device 2 for providing power to the cleaning and agitating device 1. The stirring device 1 includes at least three concentrically socketed drums 11, and a number of helically arranged baffle structures 111 are distributed on the side walls of the drums 11.

[0029] It should be noted that the cleaning and stirring device 1 includes at least three concentrically sleeved drums 11, which is beneficial to reduce the volume of the equipment and save energy consumption through cascade utilization of heat.

[0030] Wherein, the included angles between the several baffle structures 111 and the side wall of the drum 11 are all different.

[0031] In addition, one end of the cleaning and stirring device 1 is provided with a feed inlet 12, and the other end is provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com