Grinding slice of defibrator

A thermal mill and grinding disc technology, applied in textiles and papermaking, fiber raw material processing, fiber raw materials, etc. The problem of reducing the decomposition efficiency of sheet fibers, etc., achieves the effect of improving the decomposition efficiency of fibers, simple structure and strong force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

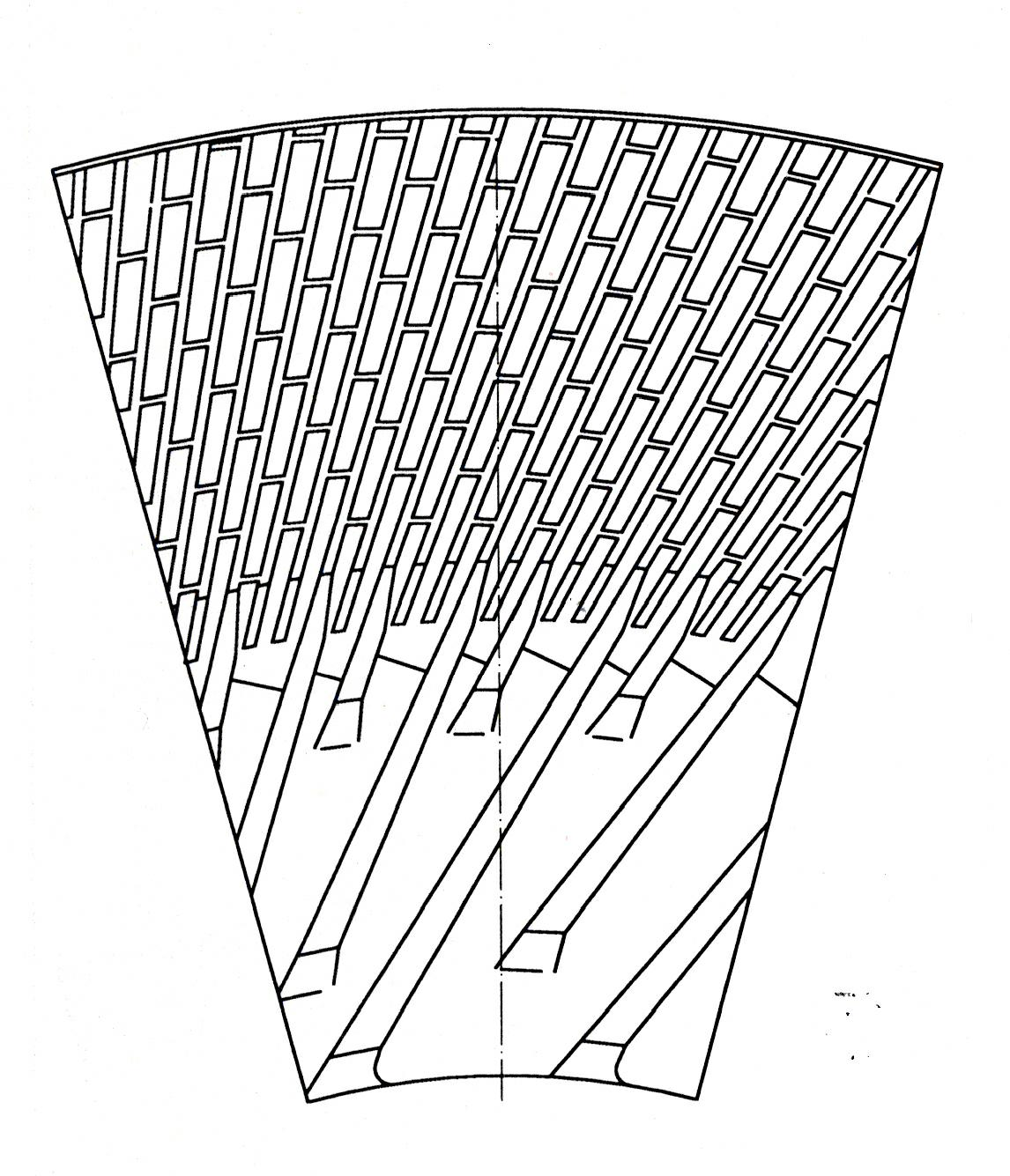

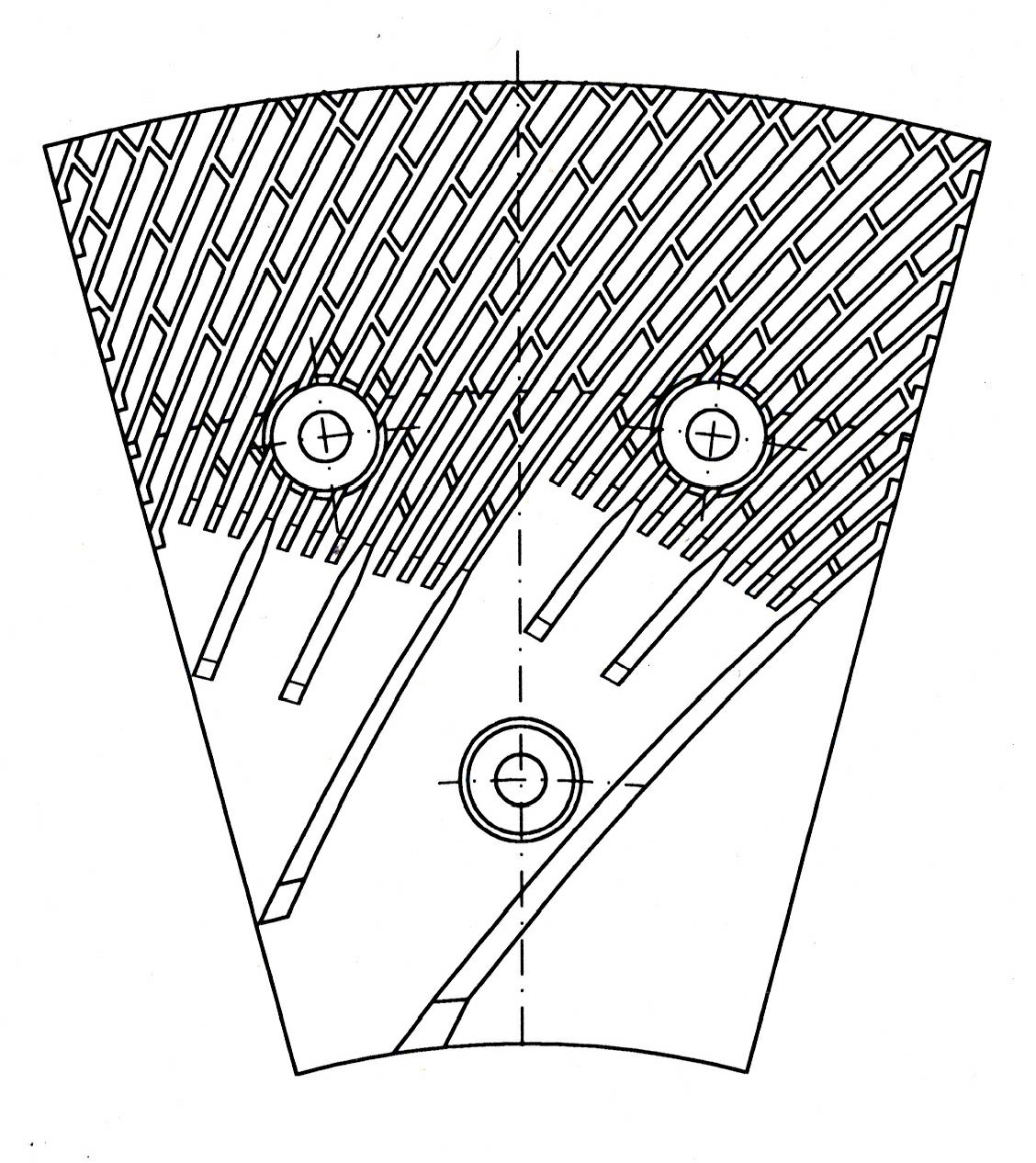

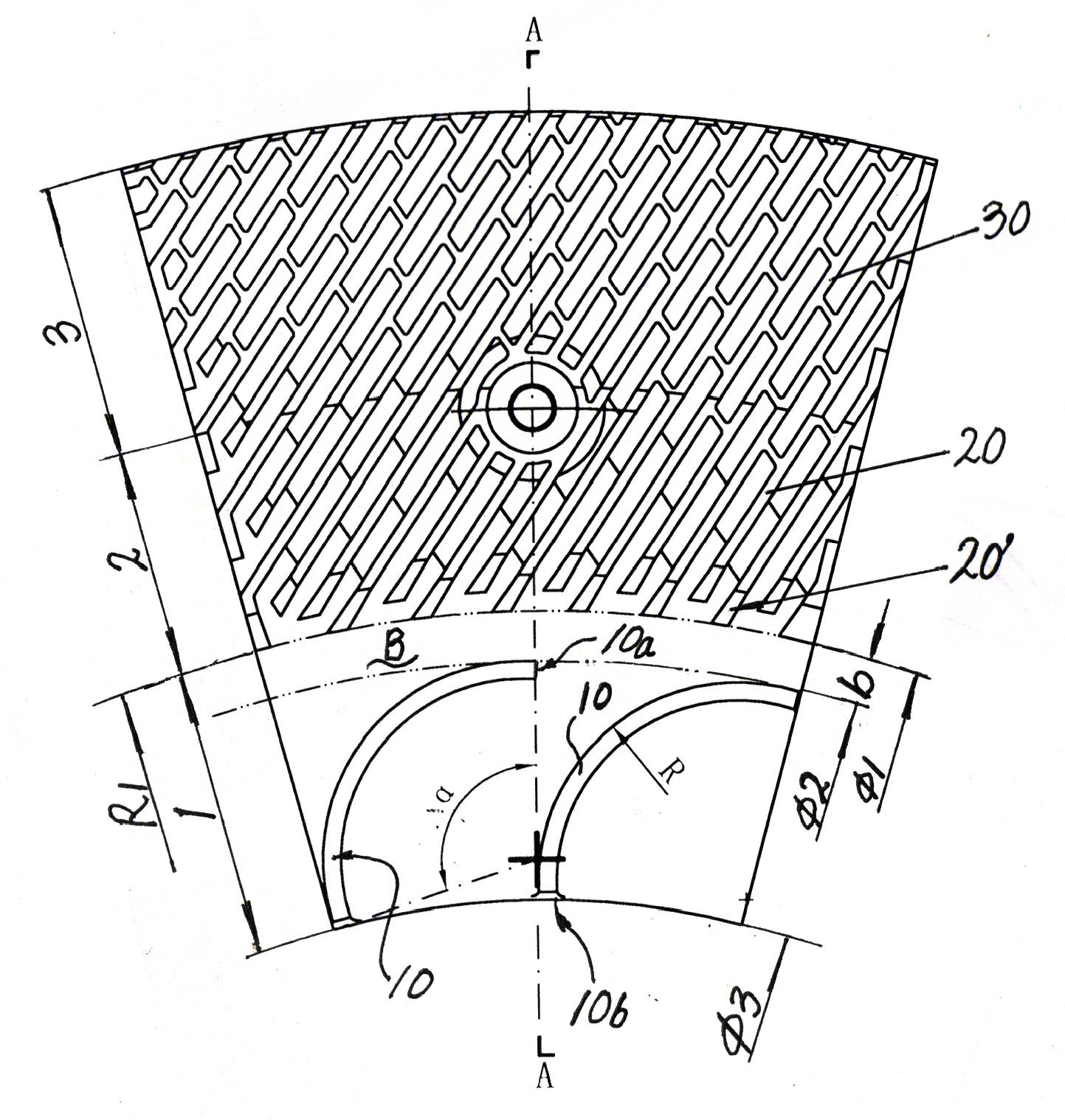

[0017] The thermal grinder grinding plate of the present invention includes a dynamic grinding plate and a static grinding plate. The grinding plate is composed of an integral disc or a combination of multiple sector plates. Grinding teeth are provided on the bottom plate of the grinding plate. From inside to outside, it is divided into crushing zone 1, rough grinding zone 2 and fine grinding zone 3. The surface of grinding teeth 20 in coarse grinding zone 2 and the surface of grinding teeth 30 in fine grinding zone 3 are connected at a certain slope. Crushing zone 1 grinds teeth. 10 is disconnected from the grinding teeth 20 of the coarse grinding area 2, the lower end 20' of the grinding teeth 20 in the rough grinding area 2 is chamfered at 30-60°, and the lower end root 20a of the grinding teeth 20 in the rough grinding area 2 forms a circular ring ?1 The ring formed with the upper end 10a of the grinding tooth 10 in the crushing zone 1 ?2 The spacing b=5-15mm, so that a c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com