Steel pipe mechanical-oiling equipment

An oiling and mechanical technology, applied in the direction of coating, liquid coating device on the surface, etc., can solve the problems of low coating efficiency, uneven coating, uneven coating, etc., to improve the quality of oil coating and facilitate coating Oil, the effect of ensuring the quality of oil coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

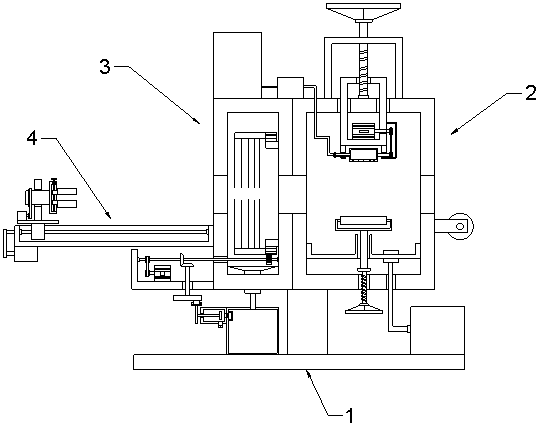

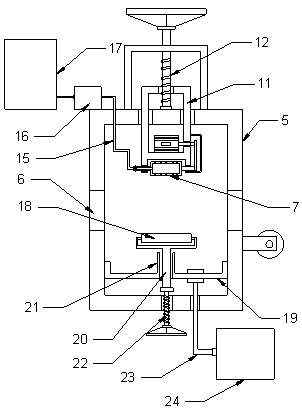

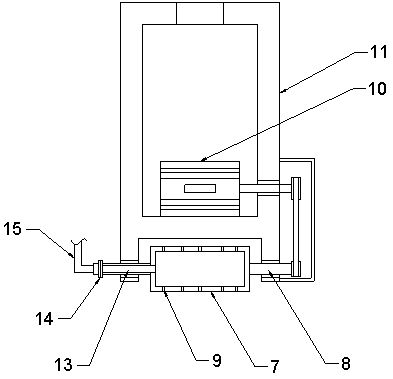

[0027] see Figure 1-7, in an embodiment of the present invention, a mechanical oiling equipment for steel pipes includes a base 1, an oiling mechanism 2 and a dust removal mechanism 3; the oiling mechanism 2 includes an oiling tank 5 fixedly connected to the base 1, and the oiling tank serves as a In the working space of oil coating, the two ends of the oil coating tank 5 are provided with circular through holes for steel pipes to enter. , the oiling tank 5 is provided with an oiling roller 7, the oiling roller 7 is a round hair roller, so that the oiling roller 7 can fully contact with the circumferential surface of the steel pipe, so that the anti-rust oil can be evenly applied to the circumference of the steel pipe On the surface, the oiling roller 7 is rotatably connected with a lifting frame 11, and the lower end surface of the lifting frame 11 is in the shape of an arc plate, so as to prevent the oiling roller 7 from being in close contact with the steel pipe surface wh...

Embodiment 2

[0031] see Figure 8 and Figure 9 The difference between this embodiment and Embodiment 1 is that: the left side of the dust removal box 25 is provided with a feed mechanism 4, the feed mechanism 4 includes a sliding frame 43 and drives the sliding frame 43 to move the linear screw module 44 laterally, and the linear wire The rod module 44 includes a screw rod, a screw motor and a linear guide rail, the screw rod motor drives the screw rod to rotate, and the screw rod drives the sliding frame 43 to move laterally on the linear guide rail, which is a prior art, and the present application will not repeat it; the sliding frame 43 is nested with a cylindrical drum 45, the drum 45 is rotationally connected with the sliding frame 43 through a bearing sleeve, the right side of the drum 45 is fixedly connected with a clamping frame 47, and the clamping frame 47 is nested with a third screw rod 49 , the third threaded mandrel 49 runs through and is threadedly connected with clamping...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com