Fire extinguishing agent filling equipment and filling method thereof

A technology of fire extinguishing agent and equipment, which is applied in the field of filling equipment in the field of fire extinguishing technology, can solve the problems of slow filling speed and filling pressure error, so as to reduce the filling pressure error, improve filling efficiency, and effectively Good for vacuuming and leak detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

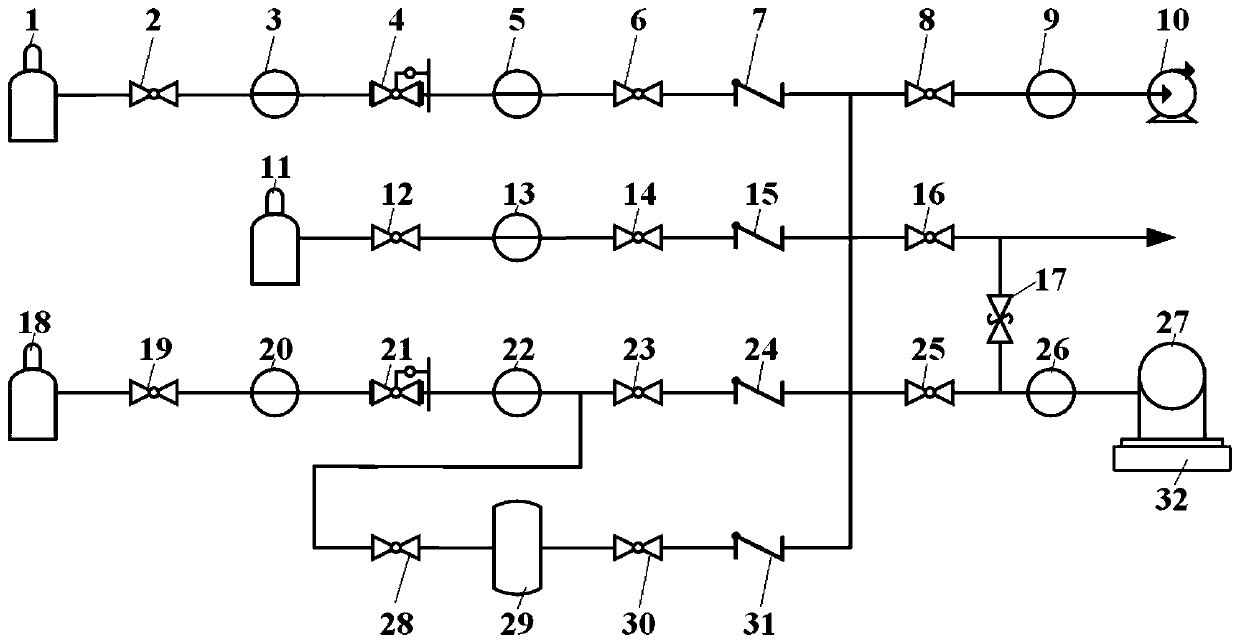

[0064] see figure 1 , the present embodiment provides a kind of fire extinguishing agent filling equipment, and this equipment is used for filling fire extinguishing agent to fire extinguisher 27. Wherein, the fire extinguishing agent filling equipment includes a vacuum pump 10, a storage container 11, a filling assembly 1, a storage container 2 29, a filling assembly 2, a storage container 3 1, a filling assembly 3, a storage container 4 18 and a filling assembly 4 , also includes a vacuum assembly, a filling control assembly, a pressure regulating assembly, a pressurized ball valve 28 and a weighing mechanism 32 . It should be noted here that the components of this embodiment may be connected by multiple pipelines, and the dimensions of the pipelines may be different. Among them, in this embodiment, all the gas pipelines are 316L stainless steel tubing with an outer diameter of 1 / 4 inch, and the pressure resistance value is 35 MPa. Each part of the aforementioned fire exti...

Embodiment 2

[0089] This embodiment provides a kind of fire extinguishing agent filling equipment, this equipment has increased controller in embodiment 1, and this controller can realize step (a) to step (e) in embodiment 1, and in this embodiment, The valves used are all electronic valves, and these valves are controlled by means of electronic control. In this embodiment, an electronic display screen and an alarm can also be added. The electronic display screen can directly display the pressure displayed by each pressure gauge, and the alarm can be set with multiple alarm messages, and can send out an alarm message when the pressure detected by the fire extinguishing agent pressure gauge 13 is lower than a pressure threshold value 1. 3. When the detected pressure is lower than a pressure threshold 2, an alarm message 2 is issued; when the pressure detected by the pressure gauge 20 on the nitrogen high pressure side is lower than a pressure threshold 3, an alarm message 3 is issued. When...

Embodiment 3

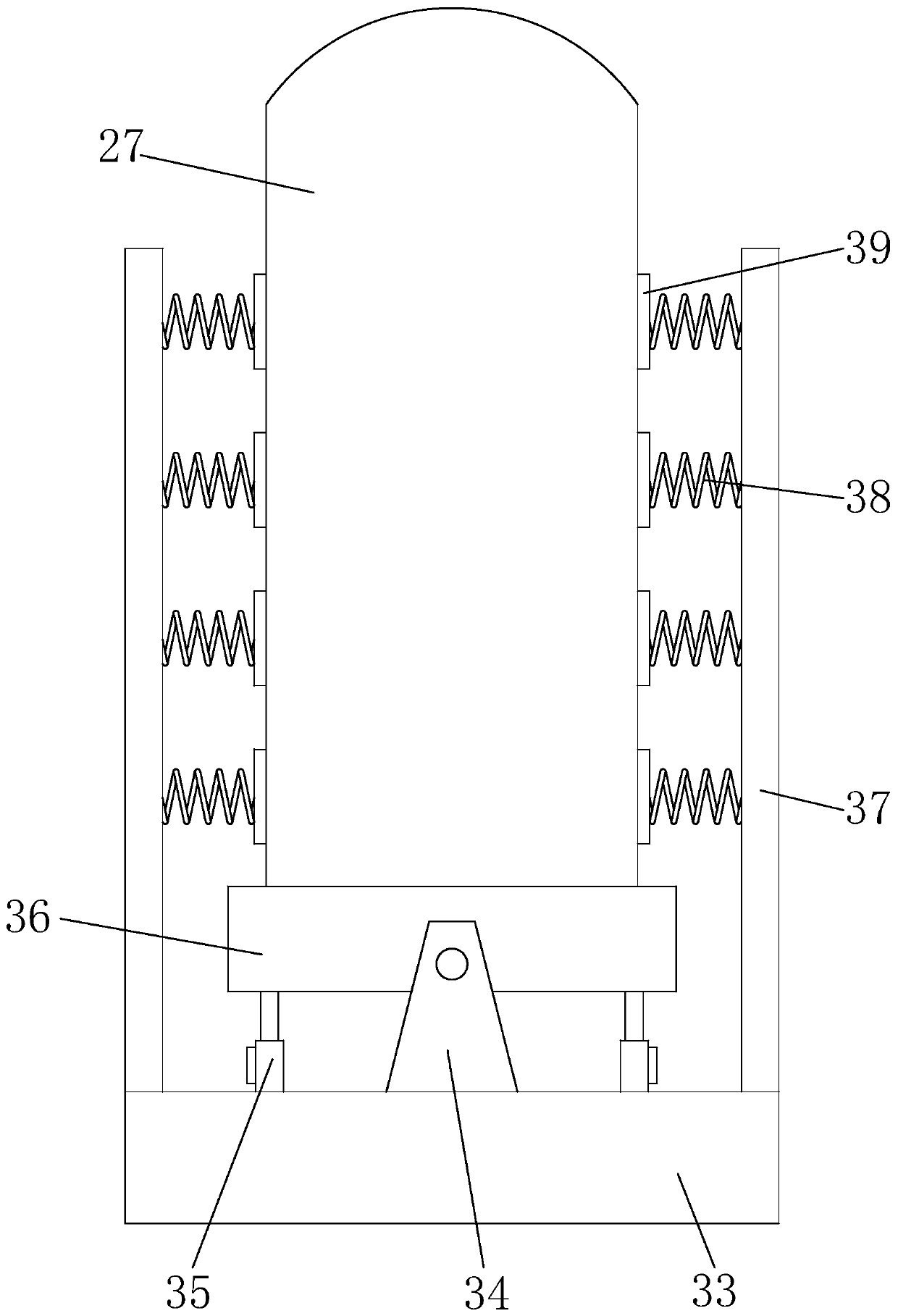

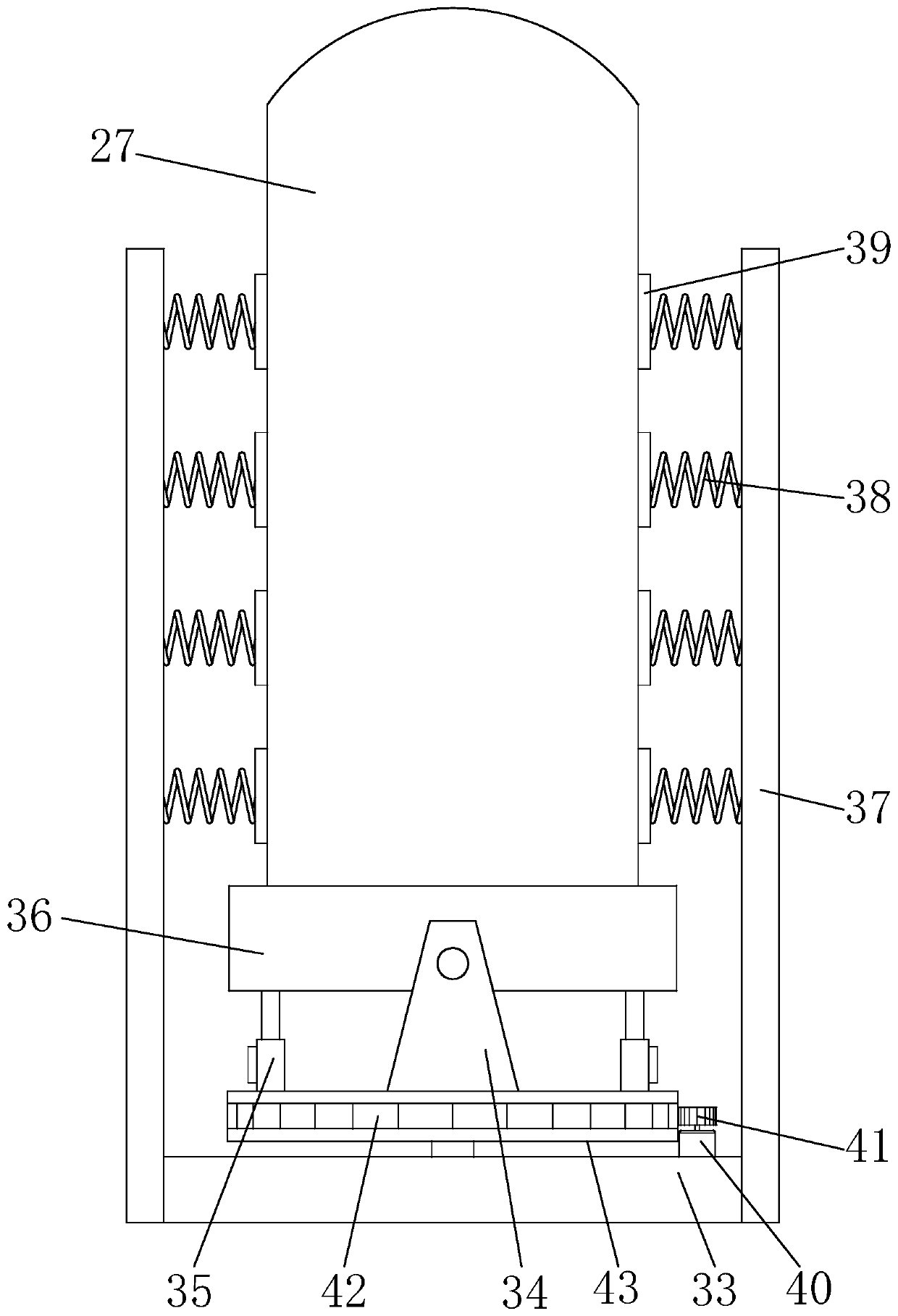

[0091] see figure 2 , The present embodiment provides a fire extinguishing agent filling equipment, which adds an automatic shaking device on the basis of Embodiment 1.

[0092] Wherein, the automatic shaking device includes a base 33, two positioning plates 34, at least one telescopic element 35, a positioning bucket 36, a supporting bucket 37 and a plurality of elastic components. The two positioning plates 34 are arranged in parallel and installed on the base 33 . The positioning bucket 36 is rotatably installed between the two positioning plates 34 and has a certain distance from the base 33 . The telescopic member 35 is installed on the base 33 , and the telescopic end is fixed to the positioning barrel 36 to drive the positioning barrel 36 to rotate relative to the base 33 . The support barrel 37 is installed on the base 33 and covers the positioning barrel 36 . Multiple elastic components are arranged between the positioning bucket 36 and the supporting bucket 37 , ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com