Blocking device for concrete conveying pipe pouring port and connection structure of blocking device

A technology for a concrete conveying pipe and a blocking device, which is applied in building construction, processing of building materials, construction, etc., can solve the problems of inconvenient production and increase of production cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

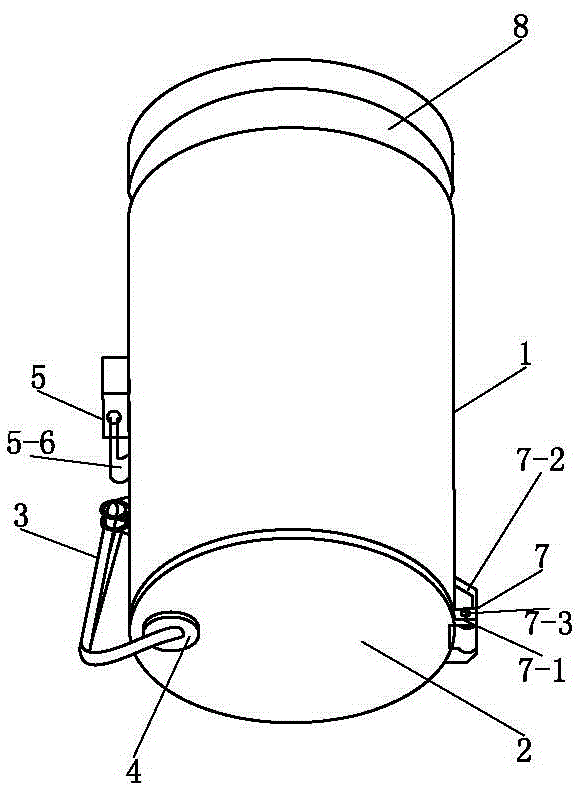

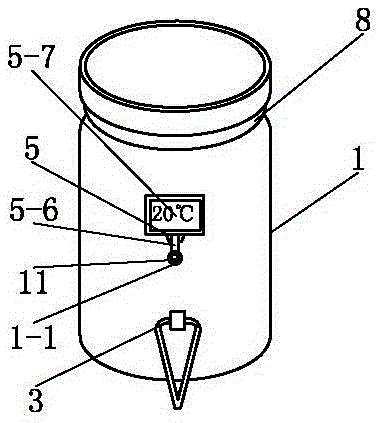

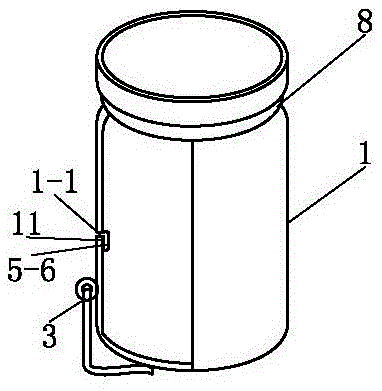

[0108] Such as Figure 1 to Figure 9 As shown, this embodiment provides a plugging device for the pouring port of a concrete delivery pipe, including a bobbin 1, one end of the bobbin 1 is a discharge port, and the bobbin 1 is provided with a device that can make the bobbin 1 The baffle plate 2 that closes or opens the discharge port of the bobbin tube 1 is movably connected. When the discharge port of the bobbin tube 1 is closed, the baffle plate 2 and the bobbin tube 1 The bobbins 1 are locked and connected by locking components 3 and 6 .

[0109] In this embodiment, when the discharge port of the bobbin is closed, the baffle plate and the bobbin are locked and connected by a locking component, so that the discharge port is always closed when it is closed. Therefore, during the movement of the pouring port of the concrete delivery pipe, the residual concrete in the concrete delivery pipe is not easy to leak out through the plugging device.

[0110] As the first step to imp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com