Fully-segmented presplitting squeezing primary-blasting mining method

A mining method and stope technology, which is applied in the field of fully segmented pre-splitting and extrusion blasting mining method of gently inclined thick and large broken ore bodies, can solve the problems of mutual interference in production, small production capacity, low labor efficiency, etc., and achieve the goal of mining The effect of short time, large production capacity and low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

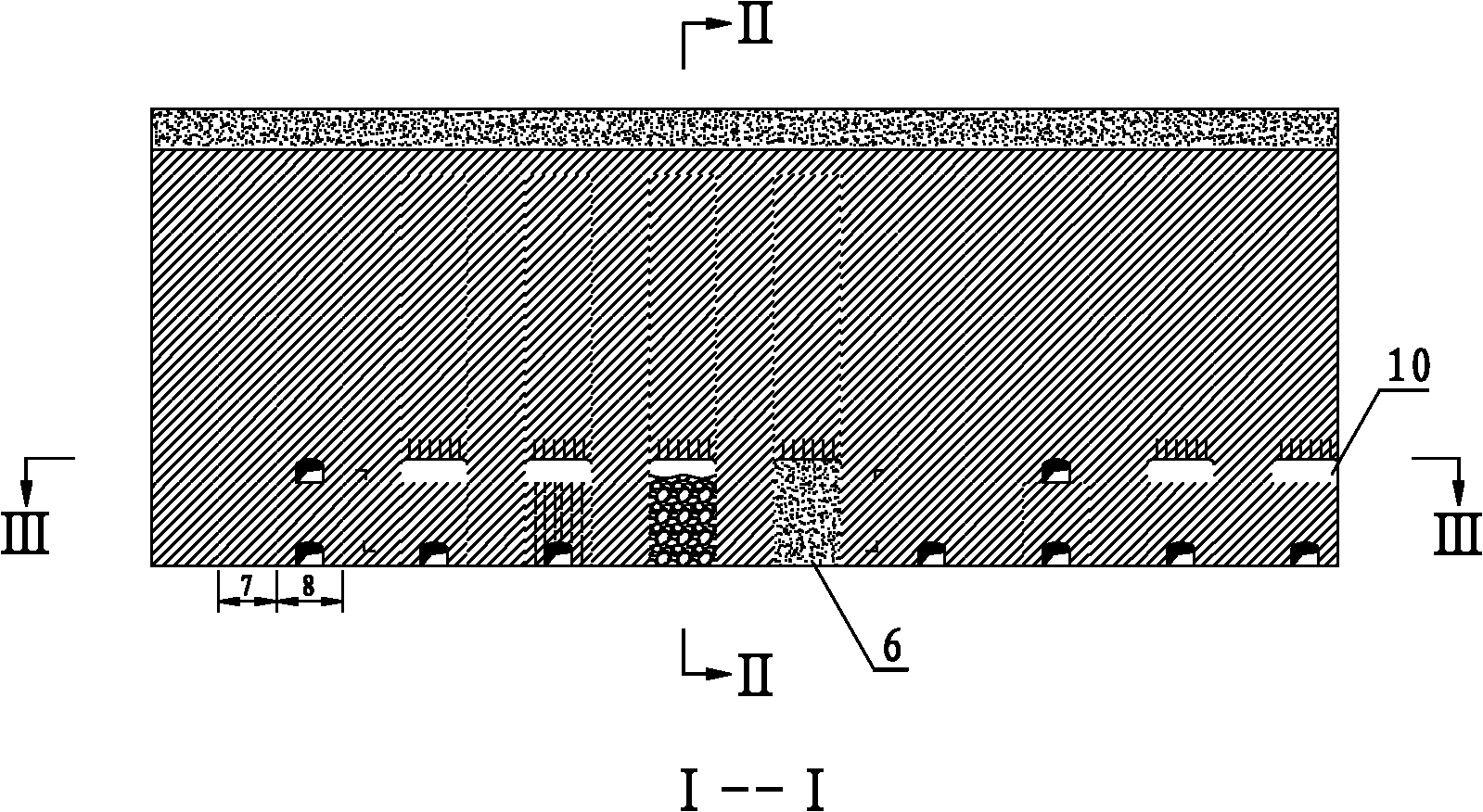

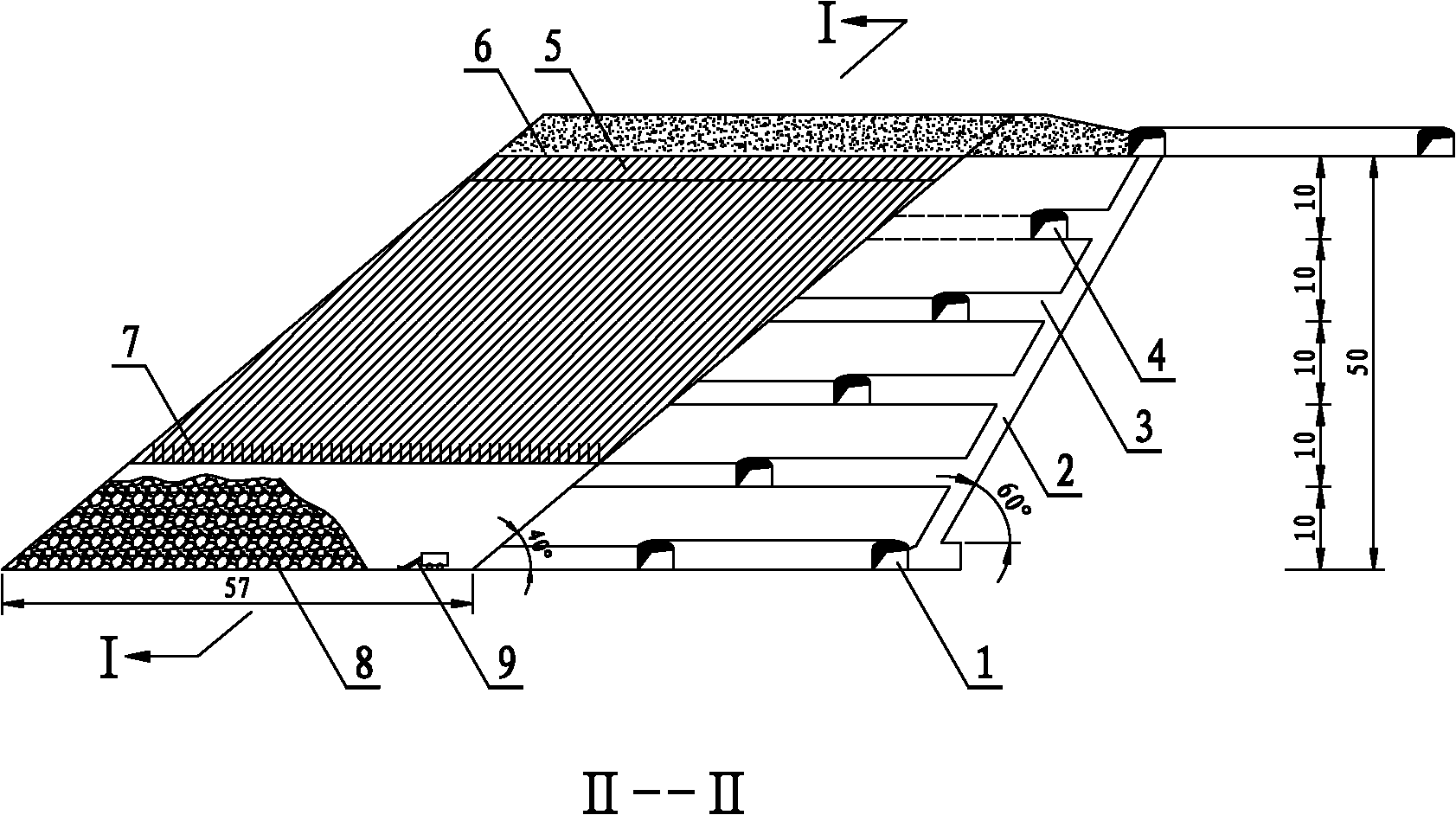

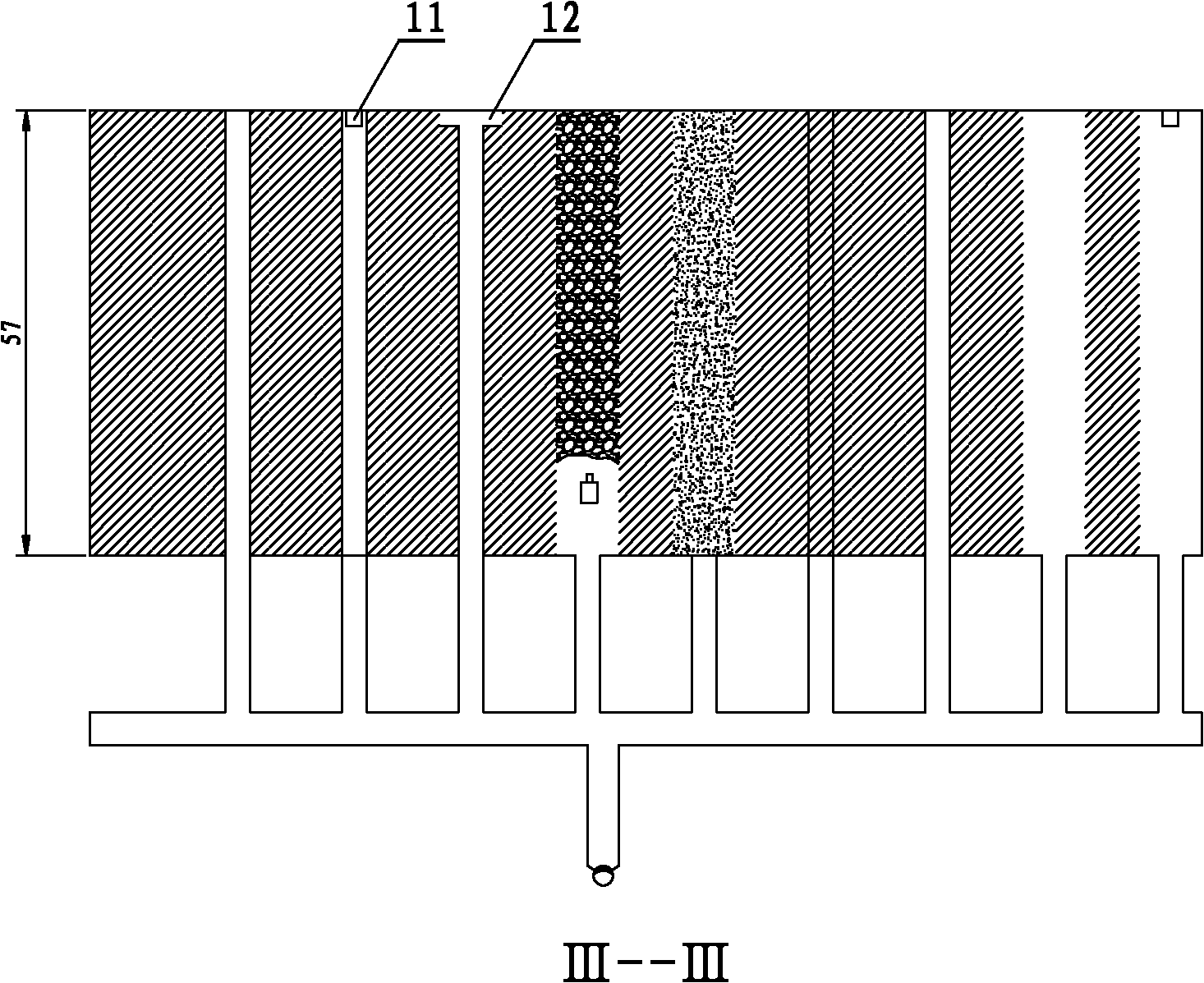

[0036] ①. The ore body is divided into stopes along the strike, and the stopes are arranged vertically. The length of the stope is the thickness of the ore body, and the width is 7-9m. It is divided into the middle section along the vertical direction. The middle section is 50m high, and the middle section is divided into subsections , with a segment height of 10m, and segmental mining from bottom to top; the stope without bottom structure adopts the trackless mining method of segmented roadway 4 outside the footwall and concentrated chute 2, and the segmented roadway 4 is arranged parallel to the boundary of the footwall of the ore body , each segmented roadway is connected with the main ramp through the segmented connecting roadway, the stope is connected with the segmented roadway through the stope connecting roadway, and the centralized chute 2 is connected with the segmented roadway 4 through the chute connecting roadway 3, as figure 1 , figure 2 and image 3 shown.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com