A filling and caving mining method

A technology of caving mining and sub-caving method, which is applied in the fields of filling, ground mining, mining equipment, etc., can solve the problems such as mixing of gravel and tailings into ore drawing, large ore loss and dilution, and deterioration of ore drawing effect, etc. The effect of low loss and dilution, high mining intensity, and no surface subsidence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

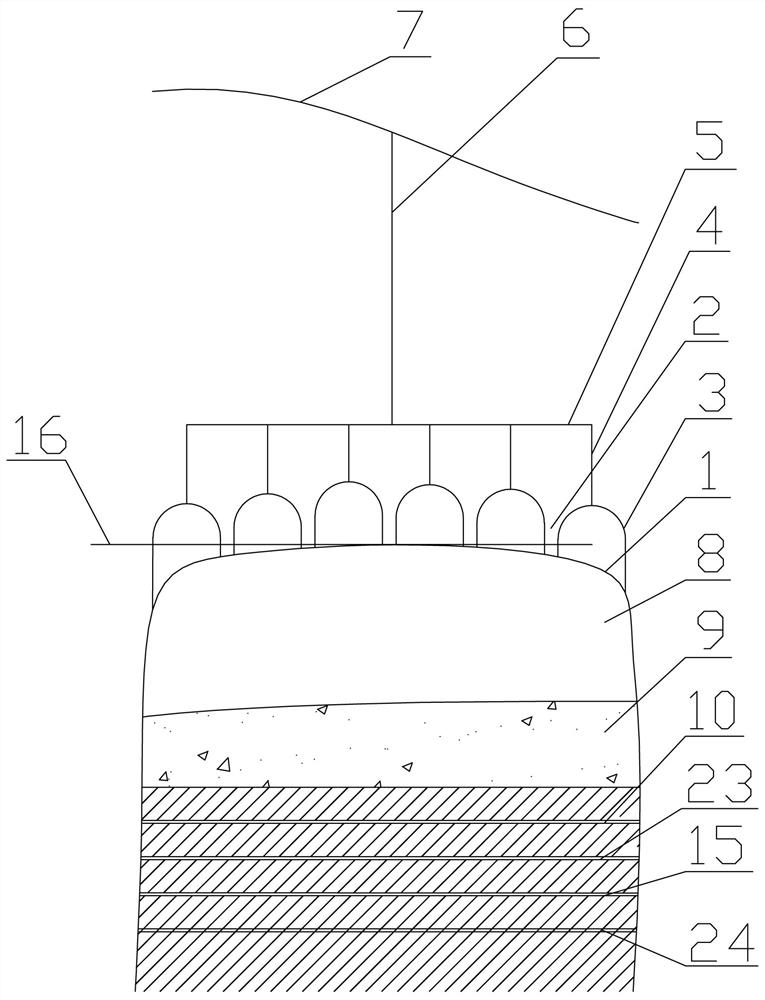

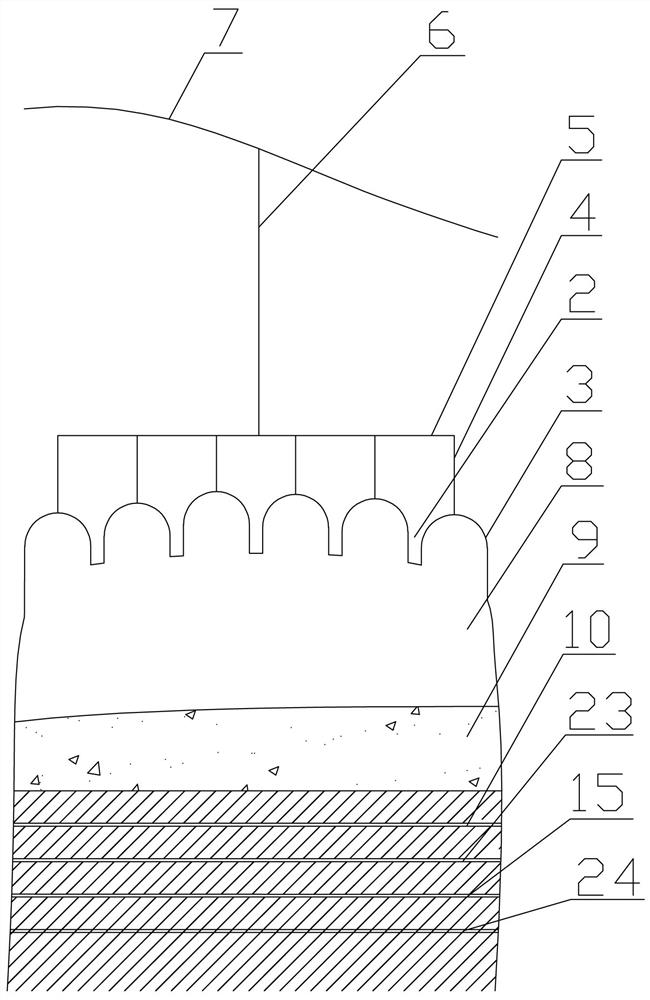

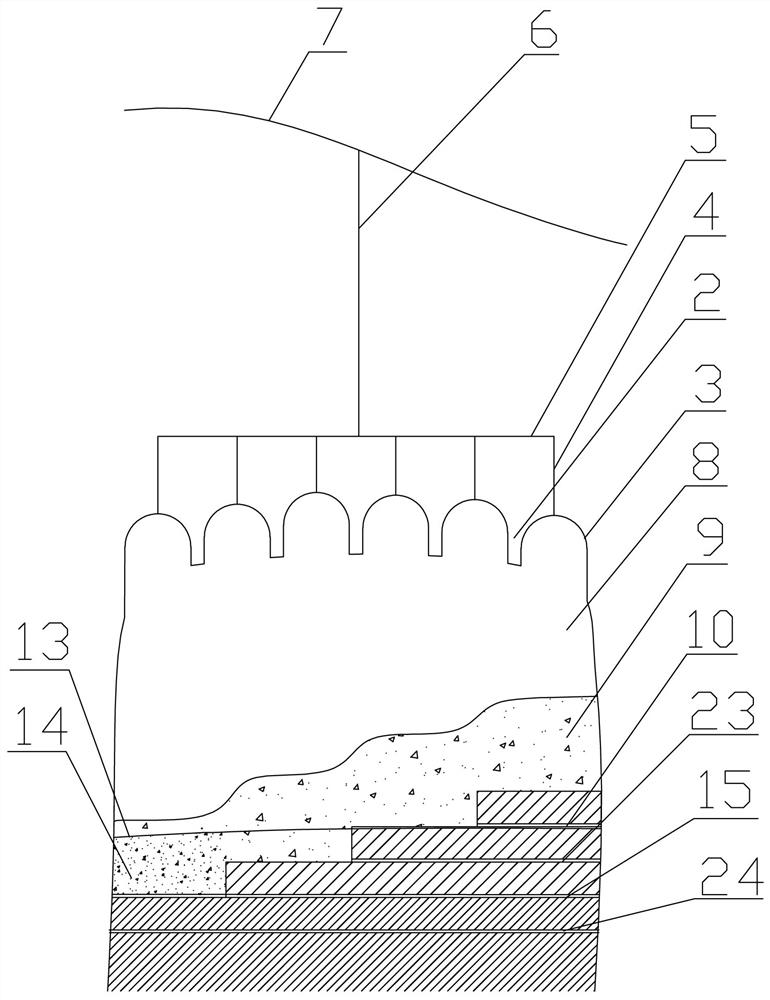

[0053] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings.

[0054] Such as figure 1 with figure 2 As shown, a filling and caving mining method of the present invention is characterized in that the ore is mined by subsection caving method without bottom pillars under the grouting cover rock layer 14, and arched suspension beams are constructed on the roof of the goaf, and the filling is carried out at the top. Concentrated filling of the goaf in the blind chute, the specific steps are as follows:

[0055] Step 1: Construct the arched suspension beam on the goaf roof and arrange the filling system

[0056] Adopt the blasting method to blast the roof 1 of the goaf 8 formed by the stepwise caving method without bottom pillars to form several arched suspension beam structures, and the arched suspension beams are composed of arches 3 and vertical beams 2; A number of filling blind chutes 4 co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com